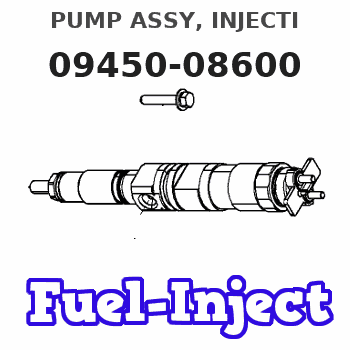

Information pump assy, injecti

Nozzle:

0935007810

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-08600 |

Scheme ###:

| 000. | [01] | 09450-08600 | PUMP ASSY, INJECTI | 1E158-51011 |

| 001. | [01] | 09011-06060 | HOUSING SUB-ASSY, | |

| 002. | [04] | 09013-00770 | HOLDER SUB-ASSY, D | |

| 003. | [04] | 09013-61260 | SPRING, DELIVERY V | |

| 004. | [04] | 09013-70250 | GASKET, DELIVERY V | |

| 004. | [08] | 09013-70100 | GASKET, DELIVERY V | 10626-24500 |

| 005. | [04] | 09014-02750 | VALVE SUB-ASSY, IN | |

| 006. | [04] | 09015-06820 | ELEMENT SUB-ASSY, | |

| 008. | [04] | 09016-30240 | SEAT, SPRING, UPR | |

| 009. | [04] | 09016-40370 | SPRING, PUMP PLUNG | |

| 010. | [04] | 09016-10640 | SLEEVE, PLUNGER CO | |

| 011. | [04] | 09017-00390 | TAPPET SUB-ASSY,IN | |

| 012. | [01] | 09021-00860 | RACK ASSY, CONTROL | |

| 015. | [01] | 09024-50170 | SCREW, HOLLOW | 15471-51321 |

| 016. | [02] | 09022-20050 | WASHER, FUEL PIPE | 15401-96652 |

| 017. | [04] | 09018-30050 | PIN, INJECTION PUM | 14611-51251 |

| 018. | [04] | 09016-50370 | SEAT, SPRING, LWR | |

| 018. | [04] | 09016-50390 | SEAT, SPRING, LWR | |

| 019. | [02] | 09046-70110 | PLATE | |

| 022. | [04] | 94914-02570 | O-RING | |

| 022. | [08] | 94914-02570 | O-RING | |

| 024. | [ C] | 09031-11140 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-11130 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10780 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10770 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10760 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10750 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10740 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10730 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10670 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10680 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10690 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10700 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10710 | PLATE, TAPPET ADJU | |

| 024. | [ C] | 09031-10720 | PLATE, TAPPET ADJU | |

| 025. | [02] | 09023-10081 | PLATE, DELIVERY VA | |

| 026. | [02] | 09023-20050 | PLATE, DELIVERY VA | |

| 028. | [02] | 94904-79210 | BOLT, W/WASHER |

Include in #3:

09450-08600

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-08600 | 1E158-5101 | PUMP ASSY, INJECTI | |

| 1E158-51011 | KUBOTA | PUMP ASSY, INJECTI |

Information:

General Information

These instructions give procedures and recommendations that will keep the possibility of damage at a minimum when engines are in storage for one year or less.After one year, the complete protection procedure must be followed again if the engine is kept in storage.The best protection for outside parts of the engine is by thorough use of paint. Paint is a good protection for a period storage of up to two years. Thoroughly clean the engine and repaint areas that have paint damage with a good quality paint.If an engine is not used, oil can run off the cylinder walls, piston rings, main bearings, connecting rod bearings, crankshaft, gears and other parts that normally get lubrication. This lack of lubricant lets corrosion start on the metal, especially in areas of high humidity (water content of the air).When the engine is started again, before these surfaces get oil, the metal-to-metal contact will cause wear. To keep this wear at a minimum, use the starter to turn the engine with the throttle in fuel OFF position until oil pressure is shown on the pressure gauge.Use an air compressor with a sprayer attachment to spray external engine parts with a mixture of 50% VCI oil and 50% engine oil to prepare the engine for storage. It should be possible to change the nozzle adjustment to give either spray or fog. The fog adjustment is better if access to components is difficult. The spray is better for parts on the outside.Volatile Corrosion Inhibitor (VCI) (NOX-RUST VCI #10 oil or equivalent) oil gives both liquid and vapor protection of ferrous metal surfaces against corrosion caused by moisture. In a closed compartment, protection is either by direct contact with VCI oil or by contact with the VCI vapors. See your local supplier for a similar type oil. Additional information as to ordering and use of NOX-RUST VCI #10 and NOX-RUST 1031B rust preventive and a list of suppliers outside the U.S.A. are available from:Daubert Chemical Co.

1200 Jorie Blvd.

Oakbrook, IL 60521

Telephone: (312) 582-1000

Attach a "DO NOT OPERATE" tag on the start switch, start button or air start knob, before servicing the engine. These tags, Form SEHS7332, are available from your Caterpillar dealer.Storage Procedure

1. Clean the outside of the engine and repaint areas that have paint damage with a good quality paint.2. Remove the batteries and use them in some other place or put them in storage where they can be checked and electrically charged again when needed. If the batteries are not removed, wash the tops. Put an electrical charge to the battery to a specific gravity of 1.275. Disconnect the battery terminals. Put a plastic cover over the battery.3. Loosen all fan, alternator belts, etc. Attach a tag to indicate what work has been done.4. Put a waterproof cover over engines with enclosures stored outdoors. Make the cover tight, but loose enough to allow air to circulate around the engine to prevent damage to exposed metal parts from condensation. Remove the waterproof cover every

These instructions give procedures and recommendations that will keep the possibility of damage at a minimum when engines are in storage for one year or less.After one year, the complete protection procedure must be followed again if the engine is kept in storage.The best protection for outside parts of the engine is by thorough use of paint. Paint is a good protection for a period storage of up to two years. Thoroughly clean the engine and repaint areas that have paint damage with a good quality paint.If an engine is not used, oil can run off the cylinder walls, piston rings, main bearings, connecting rod bearings, crankshaft, gears and other parts that normally get lubrication. This lack of lubricant lets corrosion start on the metal, especially in areas of high humidity (water content of the air).When the engine is started again, before these surfaces get oil, the metal-to-metal contact will cause wear. To keep this wear at a minimum, use the starter to turn the engine with the throttle in fuel OFF position until oil pressure is shown on the pressure gauge.Use an air compressor with a sprayer attachment to spray external engine parts with a mixture of 50% VCI oil and 50% engine oil to prepare the engine for storage. It should be possible to change the nozzle adjustment to give either spray or fog. The fog adjustment is better if access to components is difficult. The spray is better for parts on the outside.Volatile Corrosion Inhibitor (VCI) (NOX-RUST VCI #10 oil or equivalent) oil gives both liquid and vapor protection of ferrous metal surfaces against corrosion caused by moisture. In a closed compartment, protection is either by direct contact with VCI oil or by contact with the VCI vapors. See your local supplier for a similar type oil. Additional information as to ordering and use of NOX-RUST VCI #10 and NOX-RUST 1031B rust preventive and a list of suppliers outside the U.S.A. are available from:Daubert Chemical Co.

1200 Jorie Blvd.

Oakbrook, IL 60521

Telephone: (312) 582-1000

Attach a "DO NOT OPERATE" tag on the start switch, start button or air start knob, before servicing the engine. These tags, Form SEHS7332, are available from your Caterpillar dealer.Storage Procedure

1. Clean the outside of the engine and repaint areas that have paint damage with a good quality paint.2. Remove the batteries and use them in some other place or put them in storage where they can be checked and electrically charged again when needed. If the batteries are not removed, wash the tops. Put an electrical charge to the battery to a specific gravity of 1.275. Disconnect the battery terminals. Put a plastic cover over the battery.3. Loosen all fan, alternator belts, etc. Attach a tag to indicate what work has been done.4. Put a waterproof cover over engines with enclosures stored outdoors. Make the cover tight, but loose enough to allow air to circulate around the engine to prevent damage to exposed metal parts from condensation. Remove the waterproof cover every