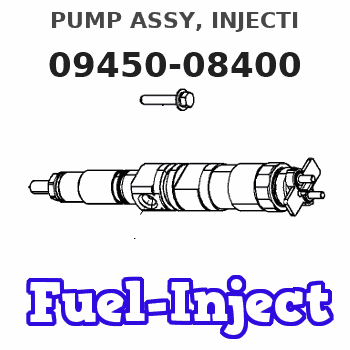

Information pump assy, injecti

Nozzle:

0935007520

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

131017961 Fuel Injection Pump Compatible with Perkins 403D-11 403C-11 Engine 094500-8400 0945008400

KoovDem Part Number: 131017961 094500-8400 0945008400 || Part Name: 131017961 094500-8400 0945008400 Fuel Injection Pump || Compatible with Perkins 403D-11 and 403C-11 engines, this product ensures optimal performance and reliability. Users can trust that it will work seamlessly with their specified engines, providing a smooth and hassle-free experience. || Please verify the accurate part number instead of solely relying on the model number. || Please carefully review the product image and part number to ensure that it is the correct item before making a purchase. This will help prevent any unnecessary returns or exchanges.

KoovDem Part Number: 131017961 094500-8400 0945008400 || Part Name: 131017961 094500-8400 0945008400 Fuel Injection Pump || Compatible with Perkins 403D-11 and 403C-11 engines, this product ensures optimal performance and reliability. Users can trust that it will work seamlessly with their specified engines, providing a smooth and hassle-free experience. || Please verify the accurate part number instead of solely relying on the model number. || Please carefully review the product image and part number to ensure that it is the correct item before making a purchase. This will help prevent any unnecessary returns or exchanges.

Fuel Injection Pump Compatible with Perkins 403D-11 403C-11 Engine 094500-8400

KoovDem Part Number: 094500-8400, 0945008400. || Compatible Model: for Perkins 403D-11 403C-11 Engine. || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 094500-8400, 0945008400. || Compatible Model: for Perkins 403D-11 403C-11 Engine. || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

Fuel Injection Pump Compatible with Perkins 403D-11 403C-11 Diesel Engine 3 Cylinder 400 Series 094500-8400 131017961 131017960

KoovDem Part Number: 131017961 131017960 094500-8400 094500-8630 094500-8120 || Engine Model: for Perkins 403D-11 403C-11 Engine, 3 Cylinder || The 403D-11 Diesel Engine Fuel Pump is a reliable and durable component designed to provide optimal fuel pressure for efficient engine operation. With precision engineering and high-quality materials, this pump ensures proper fuel delivery to the combustion chamber, resulting in optimal performance and fuel efficiency. Whether you need a replacement pump or a component for a new engine, the 403D-11 Diesel Engine Fuel Pump is a trustworthy choice for powering your diesel engine. || Friendly reminder: Before making a purchase, we suggest that you carefully review the image and part number provided in the product listing to ensure that the fuel pump you are considering is the correct one for your specific requirements. If you have any doubts or uncertainties, feel free to reach out to us with the model of your vehicle for further assistance. || Service: We offer a 3-month warranty and 24-hour customer support for all products. Feel free to reach out to us via email for any questions or concerns.

KoovDem Part Number: 131017961 131017960 094500-8400 094500-8630 094500-8120 || Engine Model: for Perkins 403D-11 403C-11 Engine, 3 Cylinder || The 403D-11 Diesel Engine Fuel Pump is a reliable and durable component designed to provide optimal fuel pressure for efficient engine operation. With precision engineering and high-quality materials, this pump ensures proper fuel delivery to the combustion chamber, resulting in optimal performance and fuel efficiency. Whether you need a replacement pump or a component for a new engine, the 403D-11 Diesel Engine Fuel Pump is a trustworthy choice for powering your diesel engine. || Friendly reminder: Before making a purchase, we suggest that you carefully review the image and part number provided in the product listing to ensure that the fuel pump you are considering is the correct one for your specific requirements. If you have any doubts or uncertainties, feel free to reach out to us with the model of your vehicle for further assistance. || Service: We offer a 3-month warranty and 24-hour customer support for all products. Feel free to reach out to us via email for any questions or concerns.

You can express buy:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-08400 |

| 001. | PUMP ASSY, INJECTI | 09450-08400 |

Scheme ###:

| 000. | [01] | 09450-08400 | PUMP ASSY, INJECTI | 131010020 |

| 000. | [01] | 09450-08400 | PUMP ASSY, INJECTI | 131010021 |

| 001. | [01] | 09011-06000 | HOUSING SUB-ASSY, | |

| 002. | [03] | 09013-00390 | HOLDER SUB-ASSY, D | 131196210 |

| 003. | [03] | 09013-60530 | SPRING, DELIVERY V | 131176430 |

| 004. | [03] | 09013-70130 | GASKET, DELIVERY V | 131186050 |

| 005. | [03] | 09014-02790 | VALVE SUB-ASSY, IN | |

| 006. | [03] | 09015-06590 | ELEMENT SUB-ASSY, | 131116670 |

| 007. | [03] | 09016-00140 | SLEEVE SUB-ASSY, C | 131296950 |

| 008. | [03] | 09016-30140 | SEAT, SPRING, UPR | 131296620 |

| 009. | [03] | 09016-40220 | SPRING, PUMP PLUNG | 131176440 |

| 010. | [03] | 09016-50170 | SEAT, SPRING, LWR | 131296621 |

| 011. | [03] | 09017-00220 | TAPPET SUB-ASSY,IN | 131256120 |

| 012. | [01] | 09021-00500 | RACK ASSY, CONTROL | 131296636 |

| 014. | [01] | 09024-50240 | SCREW, HOLLOW | 131236190 |

| 016. | [02] | 09025-10010 | WASHER, INJECTION | 131426180 |

| 017. | [03] | 09018-30090 | PIN, INJECTION PUM | 131296651 |

| 018. | [03] | 09023-00070 | PLATE SET, VALVE H | 131296662 |

| 019. | [01] | 09069-11020 | BRACKET, STOP WIRE | 131296650 |

| 020. | [02] | 94900-20500 | SCREW, COUNTERSUNK | 131136320 |

| 021. | [03] | 94900-75390 | SCREW, W/WASHER | 131136330 |

| 022. | [03] | 90801-10130 | O-RING | 131226170 |

| 022. | [03] | 09013-90400 | O-RING | |

| 023. | [01] | 94918-10430 | NIPPLE, SWIVELING | 131246130 |

| 024. | [ C] | 09031-10400 | PLATE, TAPPET ADJU | 131296630 |

| 024. | [ C] | 09031-10410 | PLATE, TAPPET ADJU | 131296631 |

| 024. | [ C] | 09031-10420 | PLATE, TAPPET ADJU | 131296632 |

| 024. | [ C] | 09031-10430 | PLATE, TAPPET ADJU | 131296633 |

| 024. | [ C] | 09031-10440 | PLATE, TAPPET ADJU | 131296634 |

| 024. | [ C] | 09031-10390 | PLATE, TAPPET ADJU | 131296629 |

| 024. | [ C] | 09031-10380 | PLATE, TAPPET ADJU | 131296628 |

| 024. | [ C] | 09031-10370 | PLATE, TAPPET ADJU | 131296627 |

| 024. | [ C] | 09031-10360 | PLATE, TAPPET ADJU | 131296626 |

| 024. | [ C] | 09031-10350 | PLATE, TAPPET ADJU | 131296625 |

| 024. | [ C] | 09031-10340 | PLATE, TAPPET ADJU | 131296624 |

| 024. | [ C] | 09031-10330 | PLATE, TAPPET ADJU | 131296623 |

| 024. | [ C] | 09031-10320 | PLATE, TAPPET ADJU | 131296622 |

| 024. | [ C] | 09031-10450 | PLATE, TAPPET ADJU | 131296635 |

Include in #3:

09450-08400

as PUMP ASSY, INJECTI

09450-08400

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-08400 | 131010020 | PUMP ASSY, INJECTI | |

| 131010021 | ISHIKAWAJIMA | PUMP ASSY, INJECTI | |

| 131010020 | ISHIKAWAJIMA | PUMP ASSY, INJECTI |

Information:

Air Cleaners (Caterpillar Dry-type Air Cleaners Only)

Regular service intervals, along with close visual inspection of the air cleaner, are necessary for proper cleaning of the engine inlet air. The service interval will vary with the weather and working conditions. Where dust conditions are severe, it will be necessary to service the air cleaner frequently. In damp weather and other conditions of little or no dust, the service interval can be extended.To extend the service life of the element, the exhaust and air cleaner inlet pipes should be arranged so that exhaust and/or oil fumes do not enter the engine air cleaner.Visual inspection of the gaskets and seals is important in keeping dust from bypassing the air cleaner. Any dirt allowed to enter, accelerates wear throughout the engine. If the condition of any of the replaceable seals and gaskets is questionable, replace them. If the sealing ends of the filter element or the element pleats are damaged, replace the element.Extra filter elements should be kept on hand for replacement or for use in the air cleaner while the element that was removed is being cleaned.The air service cleaner indicator is connected to the air inlet pipe between the air cleaner and the turbocharger. It contains a red marked piston, which gradually rises with restriction to the air flow. When the entire piston is visible it will lock in this position. This indicates a need for air cleaner service. The piston will remain in this position whether or not the engine is running. After servicing the air cleaner, reset the piston by depressing the plunger in the bottom of the indicator.

AIR CLEANER SERVICE INDICATORExcessive engine exhaust smoke and/or loss of power may indicate the need for servicing the air cleaner. Never service the air cleaner while the engine is running.Single Stage Air Cleaner

Changing Filter Element

Service the air cleaner with the engine stopped.

1. Remove the air cleaner cover and element. 2. Cover the air inlet opening to prevent foreign objects from entering the engine.3. Clean the inside of the air cleaner cover and the air cleaner body. 4. Inspect the replacement element for damage and cleanliness. Have a replacement element on hand to install and use while cleaning the dirty element. This will save you down time.5. Remove the covering from the air inlet opening.6. Install the element.

Install the air cleaner element as shown in the illustration. Note the arrows indicating air flow on the side of the element, and the position of the gasket.

7. Install the air cleaner cover.8. Reset the service indicator button by pushing on the reset button.9. Clean the used air cleaner element. See the instructions for cleaning. Cleaning Filter Elements

Cleaning Elements With Air

1. Use clean, dry air-30 PSI (2 kg/cm2) maximum. Hold the nozzle at least one inch from the element and at a slight angle.

When using pressure air, wear safety glasses and protective clothing. Use no more than 30 PSI (2 kg/cm2) pressure.

2. Direct the air stream along the complete length of each pleat on

Regular service intervals, along with close visual inspection of the air cleaner, are necessary for proper cleaning of the engine inlet air. The service interval will vary with the weather and working conditions. Where dust conditions are severe, it will be necessary to service the air cleaner frequently. In damp weather and other conditions of little or no dust, the service interval can be extended.To extend the service life of the element, the exhaust and air cleaner inlet pipes should be arranged so that exhaust and/or oil fumes do not enter the engine air cleaner.Visual inspection of the gaskets and seals is important in keeping dust from bypassing the air cleaner. Any dirt allowed to enter, accelerates wear throughout the engine. If the condition of any of the replaceable seals and gaskets is questionable, replace them. If the sealing ends of the filter element or the element pleats are damaged, replace the element.Extra filter elements should be kept on hand for replacement or for use in the air cleaner while the element that was removed is being cleaned.The air service cleaner indicator is connected to the air inlet pipe between the air cleaner and the turbocharger. It contains a red marked piston, which gradually rises with restriction to the air flow. When the entire piston is visible it will lock in this position. This indicates a need for air cleaner service. The piston will remain in this position whether or not the engine is running. After servicing the air cleaner, reset the piston by depressing the plunger in the bottom of the indicator.

AIR CLEANER SERVICE INDICATORExcessive engine exhaust smoke and/or loss of power may indicate the need for servicing the air cleaner. Never service the air cleaner while the engine is running.Single Stage Air Cleaner

Changing Filter Element

Service the air cleaner with the engine stopped.

1. Remove the air cleaner cover and element. 2. Cover the air inlet opening to prevent foreign objects from entering the engine.3. Clean the inside of the air cleaner cover and the air cleaner body. 4. Inspect the replacement element for damage and cleanliness. Have a replacement element on hand to install and use while cleaning the dirty element. This will save you down time.5. Remove the covering from the air inlet opening.6. Install the element.

Install the air cleaner element as shown in the illustration. Note the arrows indicating air flow on the side of the element, and the position of the gasket.

7. Install the air cleaner cover.8. Reset the service indicator button by pushing on the reset button.9. Clean the used air cleaner element. See the instructions for cleaning. Cleaning Filter Elements

Cleaning Elements With Air

1. Use clean, dry air-30 PSI (2 kg/cm2) maximum. Hold the nozzle at least one inch from the element and at a slight angle.

When using pressure air, wear safety glasses and protective clothing. Use no more than 30 PSI (2 kg/cm2) pressure.

2. Direct the air stream along the complete length of each pleat on