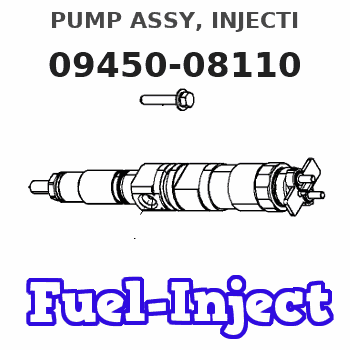

Information pump assy, injecti

Nozzle:

0935002510

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

094500-8110 0945008110 Fuel Injection Pump for Perkins 403C-11 103-10 Engine

HIRINTOL 🔸Replace Part Number: 094500-8110 0945008110 || 🔸Engine Model: for Perkins 403C-11 103-10 Engine || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

HIRINTOL 🔸Replace Part Number: 094500-8110 0945008110 || 🔸Engine Model: for Perkins 403C-11 103-10 Engine || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

Fuel Injection Pump for Ford New Holland TC24D TC23DA TC26DA TC24DA Case DX24 DX23 DX26 Tractor 131017950 131017951 094500-8110

KoovDem Part Number: 094500-8110, 0945008110, 131017950, 131017951 || Compatible Model: for Ford New Holland Tractor TC24D TC23DA TC26DA TC24DA; for Case Tractor DX24 DX23 DX26 || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 094500-8110, 0945008110, 131017950, 131017951 || Compatible Model: for Ford New Holland Tractor TC24D TC23DA TC26DA TC24DA; for Case Tractor DX24 DX23 DX26 || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

PFR3 Fuel Injection Pump Compatible with Perkins 403C-11 103-10 Engine 131017950 131017951 094500-8110

KoovDem Part Number: 131017950 131017951 094500-8110 SBA131017950 SBA131017951 || Application:For Ford New Holland TC24D TC23DA TC24DA TC26DA Tractors; for McCormick Agricultural G30R Tractors || Specifications for the Perkins 403C-11 103-10 Engine model include a compact, reliable design with X horsepower output and advanced fuel injection technology. High-quality components ensure dependable performance and durability in challenging conditions. This engine meets strict emissions standards, has low maintenance needs, and is suitable for construction, agriculture, and industrial equipment. In summary, it is a dependable and efficient power source for diverse applications. || for verification. This will help ensure that you receive the correct part for your vehicle. It is important to double check the accuracy of the part numbers to avoid any delays or inconvenience. Thank you for your attention to detail and for choosing our services. || Service: We offer a 5-month warranty on all products, along with 24-hour customer support for any inquiries or issues. If you have any questions regarding the product, please don't hesitate to reach out to us via email.

KoovDem Part Number: 131017950 131017951 094500-8110 SBA131017950 SBA131017951 || Application:For Ford New Holland TC24D TC23DA TC24DA TC26DA Tractors; for McCormick Agricultural G30R Tractors || Specifications for the Perkins 403C-11 103-10 Engine model include a compact, reliable design with X horsepower output and advanced fuel injection technology. High-quality components ensure dependable performance and durability in challenging conditions. This engine meets strict emissions standards, has low maintenance needs, and is suitable for construction, agriculture, and industrial equipment. In summary, it is a dependable and efficient power source for diverse applications. || for verification. This will help ensure that you receive the correct part for your vehicle. It is important to double check the accuracy of the part numbers to avoid any delays or inconvenience. Thank you for your attention to detail and for choosing our services. || Service: We offer a 5-month warranty on all products, along with 24-hour customer support for any inquiries or issues. If you have any questions regarding the product, please don't hesitate to reach out to us via email.

You can express buy:

USD 393.47

19-05-2025

19-05-2025

Fuel 3 Cylinder Head Rotor 104135-3080 131017951 131017950 131017640 for Engine 103.13 103.15403A-15.403D-15.403F-15

USD 636.29

19-05-2025

19-05-2025

Fuel Injection Pump 131017950 131017951 131017640 131017641 For Perkins Engine 403C-11 103-10 Shibaura Tractor ST318 ST321 ST324

Images:

USD 739.76

[03-May-2025]

Components :

| 001. | PUMP ASSY, INJECTI | 09450-08110 |

| 001. | PUMP ASSY, INJECTI | 09450-08110 |

Scheme ###:

| 000. | [01] | 09450-08110 | PUMP ASSY, INJECTI | 131017950 |

| 000. | [01] | 09450-08110 | PUMP ASSY, INJECTI | 131017951 |

| 001. | [01] | 09011-06000 | HOUSING SUB-ASSY, | |

| 002. | [03] | 09013-00390 | HOLDER SUB-ASSY, D | 131196210 |

| 003. | [03] | 09013-60530 | SPRING, DELIVERY V | 131176430 |

| 004. | [03] | 09013-70130 | GASKET, DELIVERY V | 131186050 |

| 005. | [03] | 09014-01670 | VALVE SUB-ASSY, IN | 131156160 |

| 006. | [03] | 09015-03680 | ELEMENT SUB-ASSY, | 131116400 |

| 007. | [03] | 09016-00140 | SLEEVE SUB-ASSY, C | 131296950 |

| 008. | [03] | 09016-30140 | SEAT, SPRING, UPR | 131296620 |

| 009. | [03] | 09016-40220 | SPRING, PUMP PLUNG | 131176440 |

| 010. | [03] | 09016-50170 | SEAT, SPRING, LWR | 131296621 |

| 011. | [03] | 09017-00220 | TAPPET SUB-ASSY,IN | 131256120 |

| 012. | [01] | 09021-00500 | RACK ASSY, CONTROL | 131296636 |

| 014. | [01] | 09024-50240 | SCREW, HOLLOW | 131236190 |

| 016. | [02] | 09025-10010 | WASHER, INJECTION | 131426180 |

| 017. | [03] | 09018-30090 | PIN, INJECTION PUM | 131296651 |

| 018. | [03] | 09023-00070 | PLATE SET, VALVE H | 131296662 |

| 019. | [01] | 09069-11020 | BRACKET, STOP WIRE | 131296650 |

| 020. | [02] | 94900-20500 | SCREW, COUNTERSUNK | 131136320 |

| 021. | [03] | 94900-75390 | SCREW, W/WASHER | 131136330 |

| 022. | [03] | 90801-10130 | O-RING | 131226170 |

| 022. | [03] | 09013-90400 | O-RING | |

| 023. | [01] | 94918-10430 | NIPPLE, SWIVELING | 131246130 |

| 024. | [3C] | 09031-10400 | PLATE, TAPPET ADJU | 131296630 |

| 024. | [3C] | 09031-10410 | PLATE, TAPPET ADJU | 131296631 |

| 024. | [3C] | 09031-10420 | PLATE, TAPPET ADJU | 131296632 |

| 024. | [3C] | 09031-10430 | PLATE, TAPPET ADJU | 131296633 |

| 024. | [3C] | 09031-10440 | PLATE, TAPPET ADJU | 131296634 |

| 024. | [3C] | 09031-10390 | PLATE, TAPPET ADJU | 131296629 |

| 024. | [3C] | 09031-10380 | PLATE, TAPPET ADJU | 131296628 |

| 024. | [3C] | 09031-10370 | PLATE, TAPPET ADJU | 131296627 |

| 024. | [3C] | 09031-10360 | PLATE, TAPPET ADJU | 131296626 |

| 024. | [3C] | 09031-10350 | PLATE, TAPPET ADJU | 131296625 |

| 024. | [3C] | 09031-10340 | PLATE, TAPPET ADJU | 131296624 |

| 024. | [3C] | 09031-10330 | PLATE, TAPPET ADJU | 131296623 |

| 024. | [3C] | 09031-10320 | PLATE, TAPPET ADJU | 131296622 |

| 024. | [3C] | 09031-10450 | PLATE, TAPPET ADJU | 131296635 |

Include in #3:

09450-08110

as PUMP ASSY, INJECTI

09450-08110

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-08110 | 131017950 | PUMP ASSY, INJECTI | |

| 131017951 | ISHIKAWAJIMA | PUMP ASSY, INJECTI | |

| 131017950 | ISHIKAWAJIMA | PUMP ASSY, INJECTI |

Information:

After the engine starts, and at frequent intervals while the engine is operating, the gauges should be observed. Determine the normal reading for each gauge. Investigate the cause whenever there is a significant change in the reading.Gauges

Tachometer

The tachometer indicates engine RPM. The high idle RPM and the full load RPM are stamped on the engine's information plate. The engine can be operated between these two speed limits for long periods of time without shortening engine life. Prolonged operation at high idle with little or no load can cause adverse engine operation. Engine Oil Pressure

If the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Observe the oil level. Maintain the oil level between the ADD and FULL mark on the dipstick. If the reading continues to fluctuate when the oil level is correct, stop engine and call your Caterpillar dealer. Engine Jacket Water Temperature

The engine should operate within the NORMAL (green) range. If the engine is operating in the (red) range and steam becomes apparent:1. Reduce the load and engine RPM.2. Inspect for coolant leaks.3. Determine if the engine must be shut down immediately; or if the engine can be safely cooled by reducing the load.See COOLING SYSTEM MAINTENANCE INSTRUCTIONS.

Do not add cold water to a hot engine: Cracking of engine components may occur. Allow the engine to cool, then add coolant.

If the temperature gauge reading registers in or near the cold range (white) while operating under load:1. Check the water temperature gauge for accuracy.2. Check the temperature regulators for proper temperature range. Replace regulators if necessary.See COOLING SYSTEM MAINTENANCE for DETAILS. Fuel pressure

If the fuel filter gauge registers in the OUT range, clean the primary fuel filter, if so equipped. Install new secondary or final fuel filter elements if gauge still registers OUT. See the FUEL MAINTENANCE INSTRUCTIONS and FUEL SPECIFICATIONS. Ammeter:

The ammeter reading is normal when the indicator is at or on the (+) side of zero, when the engine is running at rated speed. If indicator is to the left (-) side of zero, investigate and correct cause. Air Cleaner Service Indicator

When the gauge indicator locks in the red range, service the air cleaner. With the engine stopped; see AIR INDUCTION AND EXHAUST SYSTEM MAINTENANCE INSTRUCTIONS. Calibrated Gauges

Calibrated gauges are used on some engines to monitor the engine systems. If an abnormal engine condition develops, determine and analyze and correct the cause before a failure and downtime occurs.The operating limits given in the "OPERATING RANGES FOR ENGINES" chart are based on the engine running at continuous rated speed and load, after warm-up, using SAE 30, oil. If any of the gauges register at or outside the operating limits, investigate and correct any malfunction. See TROUBLESHOOTING GUIDE for guidance.

Shut the engine down if work on or around the engine is required.

DO NOT OPERATE THE ENGINE WITH THE GAUGES REGISTERING AT OR OUTSIDE THE LIMITS.

1. Tachometer.2. Left inlet manifold temperature.3. Right inlet manifold temperature.4. Left and right exhaust manifold

Tachometer

The tachometer indicates engine RPM. The high idle RPM and the full load RPM are stamped on the engine's information plate. The engine can be operated between these two speed limits for long periods of time without shortening engine life. Prolonged operation at high idle with little or no load can cause adverse engine operation. Engine Oil Pressure

If the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Observe the oil level. Maintain the oil level between the ADD and FULL mark on the dipstick. If the reading continues to fluctuate when the oil level is correct, stop engine and call your Caterpillar dealer. Engine Jacket Water Temperature

The engine should operate within the NORMAL (green) range. If the engine is operating in the (red) range and steam becomes apparent:1. Reduce the load and engine RPM.2. Inspect for coolant leaks.3. Determine if the engine must be shut down immediately; or if the engine can be safely cooled by reducing the load.See COOLING SYSTEM MAINTENANCE INSTRUCTIONS.

Do not add cold water to a hot engine: Cracking of engine components may occur. Allow the engine to cool, then add coolant.

If the temperature gauge reading registers in or near the cold range (white) while operating under load:1. Check the water temperature gauge for accuracy.2. Check the temperature regulators for proper temperature range. Replace regulators if necessary.See COOLING SYSTEM MAINTENANCE for DETAILS. Fuel pressure

If the fuel filter gauge registers in the OUT range, clean the primary fuel filter, if so equipped. Install new secondary or final fuel filter elements if gauge still registers OUT. See the FUEL MAINTENANCE INSTRUCTIONS and FUEL SPECIFICATIONS. Ammeter:

The ammeter reading is normal when the indicator is at or on the (+) side of zero, when the engine is running at rated speed. If indicator is to the left (-) side of zero, investigate and correct cause. Air Cleaner Service Indicator

When the gauge indicator locks in the red range, service the air cleaner. With the engine stopped; see AIR INDUCTION AND EXHAUST SYSTEM MAINTENANCE INSTRUCTIONS. Calibrated Gauges

Calibrated gauges are used on some engines to monitor the engine systems. If an abnormal engine condition develops, determine and analyze and correct the cause before a failure and downtime occurs.The operating limits given in the "OPERATING RANGES FOR ENGINES" chart are based on the engine running at continuous rated speed and load, after warm-up, using SAE 30, oil. If any of the gauges register at or outside the operating limits, investigate and correct any malfunction. See TROUBLESHOOTING GUIDE for guidance.

Shut the engine down if work on or around the engine is required.

DO NOT OPERATE THE ENGINE WITH THE GAUGES REGISTERING AT OR OUTSIDE THE LIMITS.

1. Tachometer.2. Left inlet manifold temperature.3. Right inlet manifold temperature.4. Left and right exhaust manifold