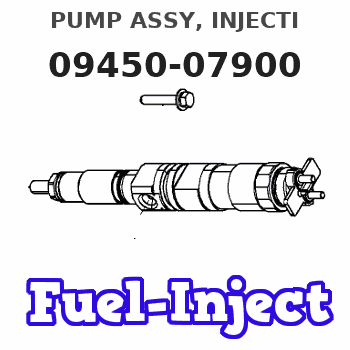

Information pump assy, injecti

Nozzle:

0935005060

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-07900 |

Scheme ###:

| 000. | [01] | 09450-07900 | PUMP ASSY, INJECTI | 1A086-51011 |

| 001. | [01] | 09011-05970 | HOUSING SUB-ASSY, | |

| 002. | [04] | 09013-00450 | HOLDER SUB-ASSY, D | 16415-51221 |

| 003. | [04] | 09013-61100 | SPRING, DELIVERY V | 16454-51231 |

| 004. | [04] | 09013-70130 | GASKET, DELIVERY V | 11420-51241 |

| 005. | [04] | 09014-02310 | VALVE SUB-ASSY, IN | 16454-51031 |

| 006. | [04] | 09015-05150 | ELEMENT SUB-ASSY, | |

| 008. | [04] | 09016-30082 | SEAT, SPRING, UPR | 15221-51271 |

| 009. | [04] | 09016-40170 | SPRING, PUMP PLUNG | 15221-51281 |

| 010. | [04] | 09016-10210 | SLEEVE, PLUNGER CO | 15221-51382 |

| 011. | [04] | 09017-00170 | TAPPET SUB-ASSY,IN | 15221-51071 |

| 011-001. | [04] | 09017-10022 | TAPPET, INJECTION | 15021-51990 |

| 011-002. | [04] | 09217-60010 | ROLLER, FEED PUMP | 15109-52931 |

| 011-003. | [04] | 09017-60020 | PIN, INJECTION PUM | 15021-51970 |

| 012. | [01] | 09021-00251 | RACK ASSY, CONTROL | 15401-51061 |

| 015. | [01] | 09024-50170 | SCREW, HOLLOW | 15471-51321 |

| 016. | [02] | 09022-20050 | WASHER, FUEL PIPE | 15401-96652 |

| 017. | [04] | 09018-30050 | PIN, INJECTION PUM | 14611-51251 |

| 018. | [04] | 09030-10060 | SEAT, SPRING, LWR | 15021-51291 |

| 019. | [02] | 09046-70030 | PLATE | 14611-51441 |

| 020. | [04] | 90802-20150 | O-RING | 14611-51201 |

| 020. | [04] | 09013-90410 | O-RING | |

| 022. | [4C] | 09031-10530 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10520 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10510 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10500 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10490 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10060 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10050 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10040 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10030 | PLATE, TAPPET ADJU | |

| 022. | [4C] | 09031-10020 | PLATE, TAPPET ADJU | |

| 025. | [02] | 09023-10081 | PLATE, DELIVERY VA | |

| 026. | [02] | 09023-20050 | PLATE, DELIVERY VA | |

| 029. | [02] | 94904-44330 | BOLT |

Include in #3:

09450-07900

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-07900 | 1A086-5101 | PUMP ASSY, INJECTI | |

| 1A086-51011 | KUBOTA | PUMP ASSY, INJECTI |

Information:

1. The customer must be asked many questions to determine whether his complaint is valid, or whether his diagnosis of an actual problem is correct.Some of the questions that must be asked are as follows:a. Does poor performance occur when the vehicle is operated at steady speed on a level road surface, or when vehicle is pulled up a grade? A positive response to either or both of the above conditions would indicate a low power (steady state) problem. Begin with Low Power Diagnosis.b. Does the poor performance always occur under the same conditions or is the problem intermittent (happens only occasionally)? This is a very important line of questioning to pursue. Any constant performance problem can normally be identified and the problem corrected. If an intermittent problem exists, the mechanic must be aware that the condition is only occasional, and must run certain tests several times in an attempt to force the malfunction condition. If the condition is not duplicated, the diagnosis that no problem exists will be incorrect, and the vehicle operator will again be confronted with the problem somewhere out on the road.c. Was the engine running rough or misfiring when the poor performance was noticed? A positive response to this question will indicate the need to isolate the bad cylinder(s) and correct the problem. See section Cylinder Misfire.2. Check the crankcase oil level and the coolant level of the radiator. Remove the boost air line from the AFRC (air-fuel ratio control) during the Primary Engine Test. This will prevent the AFRC from becoming pnuematically activated during the checks. If activated, the AFRC could give an indication of a problem when there is none.3. A slightly lower rpm (15 rpm below low limit) should be expected for the engine in vehicle than the rpm shown in the RACK SETTING INFORMATION. This is caused by the parasitic loads of the engine accessories involved.4. With the engine running, the throttle must have enough travel for the governor control lever to break over (go past the normal governor stop for high idle position) a small amount when the throttle pedal is fully depressed. If full travel is not available, disconnect throttle linkage from governor lever. With throttle linkage disconnected, full travel of governor lever will indicate linkage problems, and the linkage will have to be adjusted. Limited travel of the governor lever will indicte a problem within the governor.5. Only a mechanic with the correct training should change the high idle setting. The procedure is given in the Service Manual under the subject GOVERNOR ADJUSTMENTS.6. If high idle rpm can not be made correct with the high idle adjustment screw, there is a problem inside the governor. Disassemble the governor and check for damaged parts or wrong parts installed in the governor. Some common problems are worn bushings, worn spring seat, or a broken or wrong governor spring.7. Before 8S4627 Circuit Tester is installed, be sure to test the light for correct operation. Test light must come on