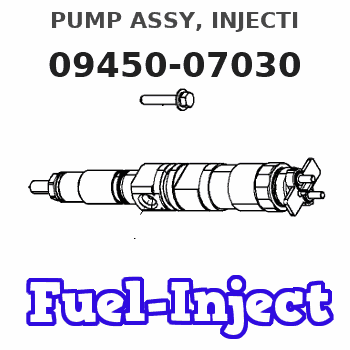

Information pump assy, injecti

Nozzle:

0935004320

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 094500-7030 0945007030 Compatible With Cub Cadet 7305 PFR3M70A1ND703

DGTYBHR The fuel pump sucks the fuel out of the tank, pressurizes it and sends it to the fuel system of the engine, and the engine gets enough fuel supply. || The pump body is the main body of the fuel pump, which contains various moving parts. || It is composed of pump body, drive mechanism, oil port, safety valve and so on. || When installing the fuel pump, ensure that the installation position is correct and the connection is firm. || Note that the import and export direction of the fuel pump cannot be reversed, otherwise it cannot be normally transmitted

DGTYBHR The fuel pump sucks the fuel out of the tank, pressurizes it and sends it to the fuel system of the engine, and the engine gets enough fuel supply. || The pump body is the main body of the fuel pump, which contains various moving parts. || It is composed of pump body, drive mechanism, oil port, safety valve and so on. || When installing the fuel pump, ensure that the installation position is correct and the connection is firm. || Note that the import and export direction of the fuel pump cannot be reversed, otherwise it cannot be normally transmitted

Fuel Injection Pump 094500-7030 0945007030 Compatible With Cub Cadet 7305 PFR3M70A1ND703

Adfghjk Compatible with Cub Cadet 7305: Designed for model 094500-7030, it perfectly matches the original fuel pressure and flow parameters to ensure efficient engine operation. || High Pressure Reinforced Fuel Supply System: Precision forged plunger and reinforced spring increase pressure resistance by 25%, suitable for high load agricultural machinery. || Anti-corrosion plating technology: Zinc-nickel alloy pump body surface treatment, resistant to rain, fertilizer corrosion, to extend the life of field operations. || Quick replacement without commissioning: Plug and play design, directly compatible with the original wiring harness and fuel line, 30 minutes to complete the installation. || Severe working condition test certification: Passed vibration, shock and salt spray triple test, complying with ISO 8528 standard.

Adfghjk Compatible with Cub Cadet 7305: Designed for model 094500-7030, it perfectly matches the original fuel pressure and flow parameters to ensure efficient engine operation. || High Pressure Reinforced Fuel Supply System: Precision forged plunger and reinforced spring increase pressure resistance by 25%, suitable for high load agricultural machinery. || Anti-corrosion plating technology: Zinc-nickel alloy pump body surface treatment, resistant to rain, fertilizer corrosion, to extend the life of field operations. || Quick replacement without commissioning: Plug and play design, directly compatible with the original wiring harness and fuel line, 30 minutes to complete the installation. || Severe working condition test certification: Passed vibration, shock and salt spray triple test, complying with ISO 8528 standard.

HGHJKZYZ Injection Pump 0945007030 Compatible with 7305 PFR3M70A1ND703 Replacement Parts

HGHJKZYZ Designed Compatible With compatibility with model 7305 PFR3M70A1ND703 to ensure integration and functionality. || Manufactured with materials, guaranteeing durability and reliability in various operating conditions. || Engineered Compatible With performance, enhancing the efficiency of your vehicle's fuel system Compatible With improved engine responsiveness. || Easy to install, making it suitable Compatible With both professional mechanics and DIY enthusiasts looking to upgrade their injection system. || Tested Compatible With quality assurance, providing peace of mind with each use and ensuring performance. || Versatile usage range, ideal Compatible With various applications in automotive and machinery sectors, accommodating diverse needs. || Cost-effective solution that delivers value without compromising on quality, making it a choice Compatible With maintenance and repairs.

HGHJKZYZ Designed Compatible With compatibility with model 7305 PFR3M70A1ND703 to ensure integration and functionality. || Manufactured with materials, guaranteeing durability and reliability in various operating conditions. || Engineered Compatible With performance, enhancing the efficiency of your vehicle's fuel system Compatible With improved engine responsiveness. || Easy to install, making it suitable Compatible With both professional mechanics and DIY enthusiasts looking to upgrade their injection system. || Tested Compatible With quality assurance, providing peace of mind with each use and ensuring performance. || Versatile usage range, ideal Compatible With various applications in automotive and machinery sectors, accommodating diverse needs. || Cost-effective solution that delivers value without compromising on quality, making it a choice Compatible With maintenance and repairs.

You can express buy:

USD 642.61

13-05-2025

13-05-2025

Fuel Injection Pump 094500-7030 For Cub Cadet 7305 PFR3M70A1ND703 Automobiles Parts Engines Parts Fuel Supply System Fuel Pumps

Components :

| 001. | PUMP ASSY, INJECTI | 09450-07030 |

Scheme ###:

| 000. | [01] | 09450-07030 | PUMP ASSY, INJECTI | |

| 005. | [01] | 09011-02830 | HOUSING SUB-ASSY, | |

| 006. | [03] | 09013-10720 | HOLDER, DELIVERY V | |

| 007. | [03] | 09013-60940 | SPRING, DELIVERY V | |

| 008. | [03] | 09013-70130 | GASKET, DELIVERY V | |

| 009. | [03] | 09014-02100 | VALVE SUB-ASSY, IN | |

| 010. | [03] | 09015-04650 | ELEMENT SUB-ASSY, | |

| 011. | [03] | 09016-10210 | SLEEVE, PLUNGER CO | |

| 012. | [03] | 09016-30082 | SEAT, SPRING, UPR | MM501098 |

| 013. | [03] | 09016-40170 | SPRING, PUMP PLUNG | |

| 014. | [03] | 09017-00170 | TAPPET SUB-ASSY,IN | EZ01775027 |

| 014-001. | [03] | 09017-10022 | TAPPET, INJECTION | |

| 014-002. | [03] | 09217-60010 | ROLLER, FEED PUMP | 09217-60010 |

| 014-003. | [03] | 09017-60020 | PIN, INJECTION PUM | |

| 015. | [03] | 09018-30050 | PIN, INJECTION PUM | |

| 016. | [01] | 09021-00470 | RACK ASSY, CONTROL | |

| 017. | [03] | 09030-10060 | SEAT, SPRING, LWR | EZ0177514 |

| 018. | [01] | 09046-70040 | PLATE | |

| 019. | [3C] | 09031-10010 | PLATE, TAPPET ADJU | 09031-10010 |

| 019. | [3C] | 09031-10310 | PLATE, TAPPET ADJU | |

| 019. | [3C] | 09031-10300 | PLATE, TAPPET ADJU | |

| 019. | [3C] | 09031-10280 | PLATE, TAPPET ADJU | |

| 019. | [3C] | 09031-10170 | PLATE, TAPPET ADJU | FR51530028 |

| 019. | [3C] | 09031-10160 | PLATE, TAPPET ADJU | FR51530027 |

| 019. | [3C] | 09031-10140 | PLATE, TAPPET ADJU | 09031-10140 |

| 019. | [3C] | 09031-10130 | PLATE, TAPPET ADJU | 09031-10130 |

| 019. | [3C] | 09031-10120 | PLATE, TAPPET ADJU | 09031-10120 |

| 019. | [3C] | 09031-10110 | PLATE, TAPPET ADJU | 09031-10110 |

| 020. | [02] | 94901-81020 | WASHER, COPPER PLA | 94901-81020 |

| 020. | [02] | 09022-20080 | WASHER, FUEL PIPE | MM500114 |

| 021. | [02] | 09024-40180 | SCREW, AIR BLEEDER | |

| 022. | [01] | 94918-00510 | SCREW, HOLLOW | MM500083 |

| 023. | [02] | 09006-80020 | PLATE, ADJUSTING | |

| 024. | [02] | 94904-80800 | BOLT, WASHER HEAD | MM514195 |

| 025. | [01] | 09055-40470 | SPRING, DIAPHRAGM | |

| 026. | [01] | 09055-40280 | SPRING, DIAPHRAGM | |

| 027. | [03] | 90802-20150 | O-RING | |

| 027. | [03] | 09013-90410 | O-RING | 47X0122700 |

| 028. | [01] | 09089-40020 | E-RING | MM501496 |

| 029. | [01] | 09089-40010 | E-RING | 09089-40010 |

| 032. | [1C] | 09021-95370 | STOPPER | |

| 032. | [1C] | 09021-95360 | STOPPER | MM501747 |

| 032. | [1C] | 09021-93120 | STOPPER | |

| 032. | [1C] | 09021-93110 | STOPPER | |

| 032. | [1C] | 09021-93100 | STOPPER | |

| 032. | [1C] | 09021-93090 | STOPPER | |

| 032. | [1C] | 09021-93080 | STOPPER | |

| 033. | [1C] | 09021-93780 | STOPPER | |

| 033. | [1C] | 09021-93790 | STOPPER | |

| 033. | [1C] | 09021-93800 | STOPPER | |

| 033. | [1C] | 09021-93810 | STOPPER | |

| 033. | [1C] | 09021-97260 | STOPPER | |

| 033. | [1C] | 09021-97270 | STOPPER | 47X0115800 |

| 033. | [1C] | 09021-97280 | STOPPER | 47X0115900 |

| 033. | [1C] | 09021-97290 | STOPPER | 47X0116000 |

| 033. | [1C] | 09021-97300 | STOPPER | 47X0116100 |

| 033. | [1C] | 09021-93770 | STOPPER | |

| 033. | [1C] | 09021-93760 | STOPPER | |

| 033. | [1C] | 09021-93670 | STOPPER | |

| 033. | [1C] | 09021-93680 | STOPPER | |

| 033. | [1C] | 09021-93690 | STOPPER | |

| 033. | [1C] | 09021-93700 | STOPPER | MM501273 |

| 033. | [1C] | 09021-93710 | STOPPER | MM501573 |

| 033. | [1C] | 09021-93720 | STOPPER | MM501274 |

| 033. | [1C] | 09021-93730 | STOPPER | 47X0115700 |

| 033. | [1C] | 09021-93740 | STOPPER | MM501275 |

| 033. | [1C] | 09021-93750 | STOPPER | |

| 033. | [1C] | 09021-97310 | STOPPER | 47X0116200 |

Include in #3:

09450-07030

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-07030 | PUMP ASSY, INJECTI |

Information:

(1) Thickness of spacer plate ... .3925 .0010 in.(9.970 0.025 mm) Thickness of spacer plate gasket ... .0082 .0010 in.(0.208 0.025 mm) For height of liner over top of spacer plate make reference to CYLINDER LINER PROJECTION.(2) Camshaft bearing bore (installed) ... 2.3150 .0020 in.(58.801 0.051 mm) Bore in block for camshaft bearings ... 2.5630 .0010 in.(65.100 0.025 mm)Depth to install camshaft bearings at both ends of block ... .06 .02 in.(1.5 0.5 mm) The camshaft bearing at the front of the block must be installed with oil holes in a horizontal position and joint at top within 15° from vertical.(3) Bore in block for main bearings (standard size) (with main bearing caps torqued) ... 3.8160 .0005 in.(96.926 0.013 mm) Bore in block for main bearings .020 in. (0.51 mm oversize) ... 3.8360 .0005 in.(97.434 0.013 mm)(4) Dimension from center of main bearing bore to top of cylinder block (new) ... 15.099 .006 in.(383.51 0.15 mm)(5) Dimension from center of main bearing bore to bottom of cylinder block (new) ... 6.063 .004 in.(154.00 0.10 mm)(6) Torque for bolts holding bearing caps for main bearings: a. Put engine oil on threads and washer face.b. Tighten all bolts to ... 30 3 lb. ft.(40 4 N m)c. Put a mark on each bolt and cap.d. Tighten all bolts from mark ... 90° Install bearing caps with the part number toward the front of the engine. Be sure that the mark (number) on the bearing cap next to the bolt hole is in agreement with the mark in the cylinder block.(7) Clearance between slot in block and bearing cap (with main bearing caps torqued) ... .0017 in.(0.043 mm) loose to ... .0013 in.(0.033 mm) tight

There are holes in the bores for the main bearings, between the cylinders for piston cooler orifices. These holes must have orifices (8) installed.

There are holes in the bores for the main bearings, between the cylinders for piston cooler orifices. These holes must have orifices (8) installed.