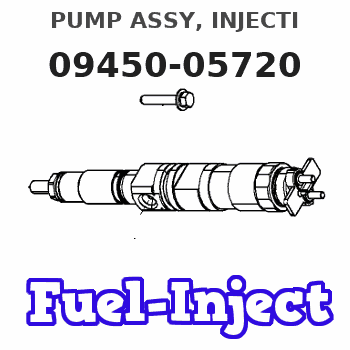

Information pump assy, injecti

Nozzle:

0935004540

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-05720 |

Scheme ###:

| 000. | [01] | 09450-05720 | PUMP ASSY, INJECTI | 16662-51011 |

| 001. | [01] | 09011-04310 | HOUSING SUB-ASSY, | 16475-51081 |

| 002. | [04] | 09013-00450 | HOLDER SUB-ASSY, D | 16415-51221 |

| 003. | [04] | 09013-60970 | SPRING, DELIVERY V | 16475-51231 |

| 004. | [04] | 09013-70130 | GASKET, DELIVERY V | 11420-51241 |

| 005. | [04] | 09014-02050 | VALVE SUB-ASSY, IN | 16475-51031 |

| 006. | [04] | 09015-05020 | ELEMENT SUB-ASSY, | |

| 008. | [04] | 09016-30082 | SEAT, SPRING, UPR | 15221-51271 |

| 009. | [04] | 09016-40170 | SPRING, PUMP PLUNG | 15221-51281 |

| 010. | [04] | 09016-10210 | SLEEVE, PLUNGER CO | 15221-51382 |

| 011. | [04] | 09017-00170 | TAPPET SUB-ASSY,IN | 15221-51071 |

| 011-001. | [04] | 09017-10021 | TAPPET, INJECTION | 15021-51990 |

| 011-002. | [04] | 09217-60010 | ROLLER, FEED PUMP | 15109-52931 |

| 011-003. | [04] | 09017-60020 | PIN, INJECTION PUM | 15021-51970 |

| 012. | [01] | 09021-00251 | RACK ASSY, CONTROL | 15401-51061 |

| 015. | [01] | 09024-50170 | SCREW, HOLLOW | 15471-51321 |

| 016. | [02] | 09022-20050 | WASHER, FUEL PIPE | 15109-51731 |

| 017. | [04] | 09018-30050 | PIN, INJECTION PUM | 14611-51251 |

| 018. | [04] | 09030-10060 | SEAT, SPRING, LWR | 15021-51291 |

| 019. | [02] | 09046-70030 | PLATE | 14611-51441 |

| 020. | [03] | 09006-80020 | PLATE, ADJUSTING | 14384-51391 |

| 021. | [03] | 94904-71980 | BOLT, W/WASHER | 15221-91031 |

| 021. | [03] | 94904-80800 | BOLT, WASHER HEAD | |

| 022. | [04] | 90802-20150 | O-RING | 14611-51201 |

| 024. | [4C] | 09031-10530 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10520 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10510 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10500 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10490 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10060 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10050 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10040 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10030 | PLATE, TAPPET ADJU | |

| 024. | [4C] | 09031-10020 | PLATE, TAPPET ADJU | |

| 029. | [02] | 94904-44330 | BOLT |

Include in #3:

09450-05720

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-05720 | 16662-5101 | PUMP ASSY, INJECTI | |

| 16662-51011 | KUBOTA | PUMP ASSY, INJECTI |

Information:

Problem

A failed sleeve or sleeve to head joint 3176 Truck Engines may cause fuel dilution of the cooling system, coolant entry into the injector cavity, or coolant entry into the cylinder.

Affected Product

Mode & Identification Number

3176 (2YG4902-9368*)

*If not previously reworked and stamped with "3S" next to Serial No. PlateParts Needed

4 - 7C2597 Gasket (water lines)5 - 8C3684 Antifreeze (gal) (if contaminated with fuel)6 - 3H2388 seal-O ring (spacer to head)6 - 4P7135 sleeve6 - 5P8066 O-ring (upper injector)1 - 1S7057 Gasket (turbo oil supply)1 - 7W2398 Gasket (turbo drain)6 - 9X7722 O-ring (lower injector)1 - 9Y7044 Gasket-Cylinder Head (only if head needs removal)Action Required

1. When it is necessary to replace a sleeve due to failure of the sleeve or the sleeve to head joint:a) Check for 3S stamped on the block next to the serial number plate. If block is stamped with 3S, change only the failed sleeve using 4P7135 sleeves. The 4C6730 Roller Expander and 4C6714 Swage must be used to install the new sleeves. See Special Instruction SEHS9246. Failure on engines marked 3S should be filed as normal warranty.b) If block is not stamped 3S replace all six sleeves using 4P7135 sleeves. The 4C6730 Roller Expander and 4C6714 Swage must be used to install the new sleeves. See Special Instruction SEHS9246.2. Ream all sleeves and check injector sleeve seating surface in head. Install the injector and check for good seat using blue dykem.3. Stamp 3S in the block next to the serial number plate after work is complete.Engine Disassembly

Cylinder Head Removal - It is possible to replace the sleeves without removing the cylinder head. See Special Instruction SEHS9246. However, in some applications it may be more efficient to remove the head. This decision is left to the dealer. Reason to remove the head must be explained in the claim story.

Off Engine Test

Test electronic unit injectors for leaks and VOP on test bench if milage is less than 150,000 mi. Replace as necessary.

Engine Assembly

1) Pressurize the cooling system to 15 psi. Look for leakage in and around sleeve cavity to check installation process. Replace any leaking sleeves.2) Test for fuel leaks past the upper injector O-rings by blocking the fuel return line and pressurizing to 100 psi. (observe for 3 minutes)3) Install the remainder of the parts to complete assembly of the engine.4) If failure resulted in fuel in the coolant, flush and fill cooling system. Flush the system for a minimum of 30 minutes using 4C4609/4C4613 Cleaner (may use 6V4511 as a substitute). Fill the cooling system using a 50% mixture of low silicate antifreeze and distilled water. If Caterpillar antifreeze is not used, add 6% cooling system conditioner.Service Claim Allowances

This a labor breakdown for in-frame repair when the block has been stamped 3S.

This is a labor breakdown (when the block has not been stamped 3S) if removal of the cylinder is needed. Head removal must be justified in the claim story.

Additional Labor segments can be claimed if necessary.

Parts Disposition

Handle the parts in accordance with your Warranty

A failed sleeve or sleeve to head joint 3176 Truck Engines may cause fuel dilution of the cooling system, coolant entry into the injector cavity, or coolant entry into the cylinder.

Affected Product

Mode & Identification Number

3176 (2YG4902-9368*)

*If not previously reworked and stamped with "3S" next to Serial No. PlateParts Needed

4 - 7C2597 Gasket (water lines)5 - 8C3684 Antifreeze (gal) (if contaminated with fuel)6 - 3H2388 seal-O ring (spacer to head)6 - 4P7135 sleeve6 - 5P8066 O-ring (upper injector)1 - 1S7057 Gasket (turbo oil supply)1 - 7W2398 Gasket (turbo drain)6 - 9X7722 O-ring (lower injector)1 - 9Y7044 Gasket-Cylinder Head (only if head needs removal)Action Required

1. When it is necessary to replace a sleeve due to failure of the sleeve or the sleeve to head joint:a) Check for 3S stamped on the block next to the serial number plate. If block is stamped with 3S, change only the failed sleeve using 4P7135 sleeves. The 4C6730 Roller Expander and 4C6714 Swage must be used to install the new sleeves. See Special Instruction SEHS9246. Failure on engines marked 3S should be filed as normal warranty.b) If block is not stamped 3S replace all six sleeves using 4P7135 sleeves. The 4C6730 Roller Expander and 4C6714 Swage must be used to install the new sleeves. See Special Instruction SEHS9246.2. Ream all sleeves and check injector sleeve seating surface in head. Install the injector and check for good seat using blue dykem.3. Stamp 3S in the block next to the serial number plate after work is complete.Engine Disassembly

Cylinder Head Removal - It is possible to replace the sleeves without removing the cylinder head. See Special Instruction SEHS9246. However, in some applications it may be more efficient to remove the head. This decision is left to the dealer. Reason to remove the head must be explained in the claim story.

Off Engine Test

Test electronic unit injectors for leaks and VOP on test bench if milage is less than 150,000 mi. Replace as necessary.

Engine Assembly

1) Pressurize the cooling system to 15 psi. Look for leakage in and around sleeve cavity to check installation process. Replace any leaking sleeves.2) Test for fuel leaks past the upper injector O-rings by blocking the fuel return line and pressurizing to 100 psi. (observe for 3 minutes)3) Install the remainder of the parts to complete assembly of the engine.4) If failure resulted in fuel in the coolant, flush and fill cooling system. Flush the system for a minimum of 30 minutes using 4C4609/4C4613 Cleaner (may use 6V4511 as a substitute). Fill the cooling system using a 50% mixture of low silicate antifreeze and distilled water. If Caterpillar antifreeze is not used, add 6% cooling system conditioner.Service Claim Allowances

This a labor breakdown for in-frame repair when the block has been stamped 3S.

This is a labor breakdown (when the block has not been stamped 3S) if removal of the cylinder is needed. Head removal must be justified in the claim story.

Additional Labor segments can be claimed if necessary.

Parts Disposition

Handle the parts in accordance with your Warranty