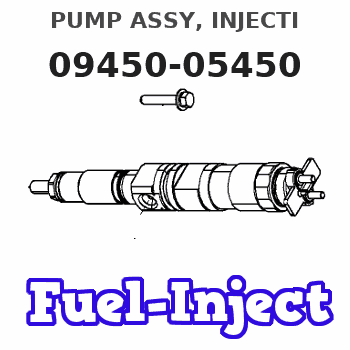

Information pump assy, injecti

Nozzle:

0935001660

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-05450 |

Scheme ###:

| 000. | [01] | 09450-05450 | PUMP ASSY, INJECTI | MM438910 |

| 005. | [01] | 09011-02590 | HOUSING SUB-ASSY, | MM501312 |

| 006. | [03] | 09013-10520 | HOLDER, DELIVERY V | MM501507 |

| 007. | [03] | 09013-60540 | SPRING, DELIVERY V | MM501161 |

| 008. | [03] | 09013-70061 | GASKET, DELIVERY V | P720-16141 |

| 008. | [03] | 09013-70130 | GASKET, DELIVERY V | MM501856 |

| 009. | [03] | 09014-00800 | VALVE SUB-ASSY, IN | MM501076 |

| 010. | [03] | 09015-02190 | ELEMENT SUB-ASSY, | MM501200 |

| 011. | [03] | 09016-10210 | SLEEVE, PLUNGER CO | MM500229 |

| 012. | [03] | 09016-30082 | SEAT, SPRING, UPR | MM501098 |

| 013. | [03] | 09016-40170 | SPRING, PUMP PLUNG | MM500360 |

| 014. | [03] | 09017-00170 | TAPPET SUB-ASSY,IN | MM500230 |

| 014-001. | [03] | 09017-10021 | TAPPET, INJECTION | |

| 014-002. | [03] | 09217-60010 | ROLLER, FEED PUMP | ME702227 |

| 014-003. | [03] | 09017-60020 | PIN, INJECTION PUM | P720-1429 |

| 015. | [03] | 09018-30050 | PIN, INJECTION PUM | MM500231 |

| 016. | [01] | 09021-00470 | RACK ASSY, CONTROL | MM501311 |

| 017. | [03] | 09030-10060 | SEAT, SPRING, LWR | MM500316 |

| 018. | [01] | 09046-70040 | PLATE | MM501162 |

| 019. | [3C] | 09031-10310 | PLATE, TAPPET ADJU | MM501365 |

| 019. | [3C] | 09031-10300 | PLATE, TAPPET ADJU | MM501364 |

| 019. | [3C] | 09031-10280 | PLATE, TAPPET ADJU | MM501246 |

| 019. | [3C] | 09031-10170 | PLATE, TAPPET ADJU | P760-15160 |

| 019. | [3C] | 09031-10160 | PLATE, TAPPET ADJU | MM500314 |

| 019. | [3C] | 09031-10140 | PLATE, TAPPET ADJU | MM500312 |

| 019. | [3C] | 09031-10130 | PLATE, TAPPET ADJU | MM500311 |

| 019. | [3C] | 09031-10120 | PLATE, TAPPET ADJU | MM500310 |

| 019. | [3C] | 09031-10110 | PLATE, TAPPET ADJU | MM500309 |

| 019. | [3C] | 09031-10010 | PLATE, TAPPET ADJU | ME702559 |

| 020. | [01] | 94901-81020 | WASHER, COPPER PLA | ME022309 |

| 020. | [01] | 09022-20080 | WASHER, FUEL PIPE | ME702235 |

| 021. | [01] | 09024-40180 | SCREW, AIR BLEEDER | MM501152 |

| 022. | [01] | 09024-50210 | SCREW, HOLLOW | MM501320 |

| 023. | [02] | 09006-80020 | PLATE, ADJUSTING | MM514109 |

| 024. | [02] | 94904-71980 | BOLT, W/WASHER | MM501244 |

| 024. | [02] | 94904-80800 | BOLT, WASHER HEAD | |

| 025. | [01] | 09055-40340 | SPRING, DIAPHRAGM | MM501382 |

| 026. | [01] | 09055-40440 | SPRING, DIAPHRAGM | MM501676 |

| 027. | [03] | 90802-20150 | O-RING | MM500438 |

| 028. | [01] | 09089-40020 | E-RING | ME702639 |

| 030. | [01] | 09089-40010 | E-RING | ME702112 |

| 031. | [1C] | 09021-92540 | STOPPER | MM501275 |

| 031. | [1C] | 09021-92530 | STOPPER | MM501260 |

| 031. | [1C] | 09021-92520 | STOPPER | MM501259 |

| 031. | [1C] | 09021-92510 | STOPPER | MM501258 |

| 031. | [1C] | 09021-92500 | STOPPER | MM501257 |

| 032. | [1C] | 09021-94090 | STOPPER | MM501352 |

| 032. | [1C] | 09021-94080 | STOPPER | MM501591 |

| 032. | [1C] | 09021-94070 | STOPPER | MM501351 |

| 032. | [1C] | 09021-94060 | STOPPER | MM501590 |

| 032. | [1C] | 09021-94050 | STOPPER | MM501350 |

| 032. | [1C] | 09021-94040 | STOPPER | MM501589 |

| 032. | [1C] | 09021-94030 | STOPPER | MM501349 |

| 032. | [1C] | 09021-94020 | STOPPER | MM501588 |

| 032. | [1C] | 09021-94010 | STOPPER | MM501348 |

| 032. | [1C] | 09021-94000 | STOPPER | MM501587 |

| 032. | [1C] | 09021-93990 | STOPPER | MM501347 |

| 032. | [1C] | 09021-93980 | STOPPER | MM501586 |

| 032. | [1C] | 09021-93970 | STOPPER | MM501346 |

| 032. | [1C] | 09021-93960 | STOPPER | MM501585 |

| 032. | [1C] | 09021-94100 | STOPPER | MM501592 |

Include in #3:

09450-05450

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-05450 | MM438910 | PUMP ASSY, INJECTI | |

| MM438910 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Introduction

Table 1

Revision History

Revision Summary of Changes

02 Updated machine effectivity

01 Pressure value was changed from 6500 psi to 5000 psi at Nozzle Tester Group and Fuel Collector section and Injector Test Procedure section. The purpose of this test procedure is to inspect the injector for leakage and observe the injection spray pattern for uneven spray.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.References

Reference: Refer to Special Publication , NENG2500 , "Dealer Service Tool Catalog" , for tools and supplies suitable to collect and contain fluids on Cat products.Safety Section

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Required Tools

Table 2

Required Tools

Item Qty Part Number Part Name

T1 1 440-6907 Injector Test Kit

T2 1 5P-4150 Nozzle Testing Group

T3 2 8S-2270 Fuel Collector

T4 1 - Battery Injector Test Kit

Illustration 1 g06345147

Injector test kit

Nozzle Tester Group and Fuel Collector

Use a correct nozzle tester or pop tester that is able to build (5000 psi) fuel pressure. Use the fuel collector to contain the spray from injector. Reference below to see container, use suitable container.

Illustration 2 g06345166

5P-4150 Nozzle Testing Group

Table 1

Revision History

Revision Summary of Changes

02 Updated machine effectivity

01 Pressure value was changed from 6500 psi to 5000 psi at Nozzle Tester Group and Fuel Collector section and Injector Test Procedure section. The purpose of this test procedure is to inspect the injector for leakage and observe the injection spray pattern for uneven spray.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.References

Reference: Refer to Special Publication , NENG2500 , "Dealer Service Tool Catalog" , for tools and supplies suitable to collect and contain fluids on Cat products.Safety Section

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Failure to follow all safety guidelines prescribed in this document and by governing authorities and regulatory agencies may result in severe injury or death of personnel or machine damage.

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Required Tools

Table 2

Required Tools

Item Qty Part Number Part Name

T1 1 440-6907 Injector Test Kit

T2 1 5P-4150 Nozzle Testing Group

T3 2 8S-2270 Fuel Collector

T4 1 - Battery Injector Test Kit

Illustration 1 g06345147

Injector test kit

Nozzle Tester Group and Fuel Collector

Use a correct nozzle tester or pop tester that is able to build (5000 psi) fuel pressure. Use the fuel collector to contain the spray from injector. Reference below to see container, use suitable container.

Illustration 2 g06345166

5P-4150 Nozzle Testing Group