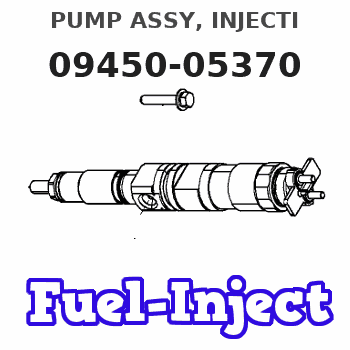

Information pump assy, injecti

Nozzle:

0935004310

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-05370 |

Scheme ###:

| 000. | [01] | 09450-05370 | PUMP ASSY, INJECTI | 30A6500500 |

| 005. | [01] | 09011-02590 | HOUSING SUB-ASSY, | |

| 006. | [03] | 09013-10720 | HOLDER, DELIVERY V | |

| 007. | [03] | 09013-60900 | SPRING, DELIVERY V | MM514003 |

| 008. | [03] | 09013-70130 | GASKET, DELIVERY V | |

| 009. | [03] | 09014-02030 | VALVE SUB-ASSY, IN | |

| 010. | [03] | 09015-04640 | ELEMENT SUB-ASSY, | |

| 011. | [03] | 09016-10210 | SLEEVE, PLUNGER CO | |

| 012. | [03] | 09016-30082 | SEAT, SPRING, UPR | MM501098 |

| 013. | [03] | 09016-40170 | SPRING, PUMP PLUNG | |

| 014. | [03] | 09017-00170 | TAPPET SUB-ASSY,IN | EZ01775027 |

| 014-001. | [03] | 09017-10022 | TAPPET, INJECTION | |

| 014-002. | [03] | 09217-60010 | ROLLER, FEED PUMP | 09217-60010 |

| 014-003. | [03] | 09017-60020 | PIN, INJECTION PUM | |

| 015. | [03] | 09018-30050 | PIN, INJECTION PUM | |

| 016. | [01] | 09021-00470 | RACK ASSY, CONTROL | |

| 017. | [03] | 09030-10060 | SEAT, SPRING, LWR | EZ0177514 |

| 018. | [01] | 09046-70040 | PLATE | |

| 019. | [3C] | 09031-10310 | PLATE, TAPPET ADJU | |

| 019. | [3C] | 09031-10300 | PLATE, TAPPET ADJU | |

| 019. | [3C] | 09031-10280 | PLATE, TAPPET ADJU | |

| 019. | [3C] | 09031-10170 | PLATE, TAPPET ADJU | FR51530028 |

| 019. | [3C] | 09031-10160 | PLATE, TAPPET ADJU | FR51530027 |

| 019. | [3C] | 09031-10140 | PLATE, TAPPET ADJU | 09031-10140 |

| 019. | [3C] | 09031-10130 | PLATE, TAPPET ADJU | 09031-10130 |

| 019. | [3C] | 09031-10120 | PLATE, TAPPET ADJU | 09031-10120 |

| 019. | [3C] | 09031-10110 | PLATE, TAPPET ADJU | 09031-10110 |

| 019. | [3C] | 09031-10010 | PLATE, TAPPET ADJU | 09031-10010 |

| 022. | [01] | 94918-00050 | SCREW, HOLLOW | 34061-06200 |

| 023. | [01] | 09006-80020 | PLATE, ADJUSTING | |

| 024. | [02] | 94904-80800 | BOLT, WASHER HEAD | MM514195 |

| 024. | [02] | 94904-71980 | BOLT, W/WASHER | |

| 025. | [01] | 09055-40470 | SPRING, DIAPHRAGM | |

| 026. | [01] | 09055-40280 | SPRING, DIAPHRAGM | |

| 027. | [03] | 90802-20150 | O-RING | |

| 027. | [03] | 09013-90410 | O-RING | 47X0122700 |

| 028. | [01] | 09089-40020 | E-RING | MM501496 |

| 029. | [01] | 09089-40010 | E-RING | 09089-40010 |

| 032. | [1C] | 09021-95370 | STOPPER | |

| 032. | [1C] | 09021-95360 | STOPPER | MM501747 |

| 032. | [1C] | 09021-93120 | STOPPER | |

| 032. | [1C] | 09021-93110 | STOPPER | |

| 032. | [1C] | 09021-93100 | STOPPER | |

| 032. | [1C] | 09021-93090 | STOPPER | |

| 032. | [1C] | 09021-93080 | STOPPER | |

| 033. | [1C] | 09021-93690 | STOPPER | |

| 033. | [1C] | 09021-93700 | STOPPER | MM501273 |

| 033. | [1C] | 09021-93710 | STOPPER | |

| 033. | [1C] | 09021-93720 | STOPPER | MM501274 |

| 033. | [1C] | 09021-93730 | STOPPER | |

| 033. | [1C] | 09021-93740 | STOPPER | |

| 033. | [1C] | 09021-93680 | STOPPER | |

| 033. | [1C] | 09021-93670 | STOPPER | |

| 033. | [1C] | 09021-93660 | STOPPER | |

| 033. | [1C] | 09021-93650 | STOPPER | |

| 033. | [1C] | 09021-93640 | STOPPER | |

| 033. | [1C] | 09021-93630 | STOPPER | |

| 033. | [1C] | 09021-93620 | STOPPER | |

| 033. | [1C] | 09021-93610 | STOPPER | |

| 033. | [1C] | 09021-93750 | STOPPER |

Include in #3:

09450-05370

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-05370 | 30A6500500 | PUMP ASSY, INJECTI | |

| 30A6500500 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Introduction

Table 1

Revision Summary of Changes in SEBF9180

06 Added new serial number prefixes for New Product Introduction (NPI).

Updated copyright date to 2018.

Removed old Repair Process Engineering point of contacts.

Added new Repair Process Engineering point of contact.

Added Caterpillar confidential yellow statement to introduction.

Removed NENG2500 "Dealer Service Tool Catalog"from References table.

Added PERJ1017 "Dealer Service Tool Catalog" to References table.

05 Updated Introduction.

Added "Think Safety" graphic.

Updated Reference Table.

Added 383-4255 Contamination Monitor Group to Tooling and Equipment.

04 Updated Introduction.

Added Canceled Replaced Part Numbers statement.

Added Safety Information.

PEJT5025 canceled replaced by PEGJ0045.

03 Added SEPD1173 to References.

Inserted a warning in the Preparation of Apparatus section.

Inserted the copyright line of text. © 2018 Caterpillar All Rights Reserved. This guideline is for the use of Cat dealers only. Unauthorized use of this document or the proprietary processes therein without permission may be violation of intellectual property law.Information contained in this document is considered Caterpillar: Confidential Yellow.This guideline enables dealers and customers to benefit from cost reductions which were made possible through an established Contamination Control Program. Fluids that are used in Caterpillar machines are highly effective unless the fluid contains damaging amounts of contaminates. Therefore, every effort must be made to reduce the contamination level within Caterpillar fluid systems. Caterpillar makes ongoing changes and improvements to the Caterpillar products. This guideline must be used with the latest technical information available from Caterpillar to ensure that such changes and improvements are incorporated when applicable.For technical questions when using this document, work with your Dealer Technical Communicator (TC).To report suspected errors, inaccuracies, or suggestions regarding the document, submit a form for feedback in the Service Information System (SIS Web) Interface.Canceled Part Numbers and Replaced Part Numbers

This document may include canceled part numbers and replaced part numbers. Use NPR on SIS for information about canceled part numbers and replaced part numbers. NPR will provide the current part numbers for replaced parts.Summary

Diesel fuel that is contaminated with debris and/or water is the primary cause of fuel system failures. Proper storage, handling, and filtration of diesel fuel minimizes the risk of fuel system failure due to contaminated fuel. Particle counting of diesel fuel is a quick and informative tool. Particle counting will evaluate the effectiveness of the storage, handling, and filtration processes by checking the fuel cleanliness.Read and understand this procedure as well as any operating manuals for the equipment used in processing and or analyzing fuel samples.Important Safety Information

Illustration 1 g02139237Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly.Improper operation, lubrication, maintenance, or repair of this product is dangerous. Improper methods could result in injury or death.Do not operate or perform any lubrication, maintenance, or repair of this product, until you understand the operation, lubrication, maintenance, and repair information. Safety precautions and warnings

Table 1

Revision Summary of Changes in SEBF9180

06 Added new serial number prefixes for New Product Introduction (NPI).

Updated copyright date to 2018.

Removed old Repair Process Engineering point of contacts.

Added new Repair Process Engineering point of contact.

Added Caterpillar confidential yellow statement to introduction.

Removed NENG2500 "Dealer Service Tool Catalog"from References table.

Added PERJ1017 "Dealer Service Tool Catalog" to References table.

05 Updated Introduction.

Added "Think Safety" graphic.

Updated Reference Table.

Added 383-4255 Contamination Monitor Group to Tooling and Equipment.

04 Updated Introduction.

Added Canceled Replaced Part Numbers statement.

Added Safety Information.

PEJT5025 canceled replaced by PEGJ0045.

03 Added SEPD1173 to References.

Inserted a warning in the Preparation of Apparatus section.

Inserted the copyright line of text. © 2018 Caterpillar All Rights Reserved. This guideline is for the use of Cat dealers only. Unauthorized use of this document or the proprietary processes therein without permission may be violation of intellectual property law.Information contained in this document is considered Caterpillar: Confidential Yellow.This guideline enables dealers and customers to benefit from cost reductions which were made possible through an established Contamination Control Program. Fluids that are used in Caterpillar machines are highly effective unless the fluid contains damaging amounts of contaminates. Therefore, every effort must be made to reduce the contamination level within Caterpillar fluid systems. Caterpillar makes ongoing changes and improvements to the Caterpillar products. This guideline must be used with the latest technical information available from Caterpillar to ensure that such changes and improvements are incorporated when applicable.For technical questions when using this document, work with your Dealer Technical Communicator (TC).To report suspected errors, inaccuracies, or suggestions regarding the document, submit a form for feedback in the Service Information System (SIS Web) Interface.Canceled Part Numbers and Replaced Part Numbers

This document may include canceled part numbers and replaced part numbers. Use NPR on SIS for information about canceled part numbers and replaced part numbers. NPR will provide the current part numbers for replaced parts.Summary

Diesel fuel that is contaminated with debris and/or water is the primary cause of fuel system failures. Proper storage, handling, and filtration of diesel fuel minimizes the risk of fuel system failure due to contaminated fuel. Particle counting of diesel fuel is a quick and informative tool. Particle counting will evaluate the effectiveness of the storage, handling, and filtration processes by checking the fuel cleanliness.Read and understand this procedure as well as any operating manuals for the equipment used in processing and or analyzing fuel samples.Important Safety Information

Illustration 1 g02139237Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly.Improper operation, lubrication, maintenance, or repair of this product is dangerous. Improper methods could result in injury or death.Do not operate or perform any lubrication, maintenance, or repair of this product, until you understand the operation, lubrication, maintenance, and repair information. Safety precautions and warnings