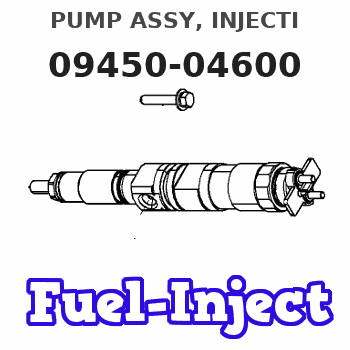

Information pump assy, injecti

Nozzle:

0935003350

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-04600 |

Scheme ###:

| 000. | [01] | 09450-04600 | PUMP ASSY, INJECTI | 16361-51012 |

| 001. | [01] | 09011-01481 | HOUSING SUB-ASSY, | |

| 005. | [06] | 09013-10280 | HOLDER, DELIVERY V | 15601-51221 |

| 005. | [06] | 09013-10520 | HOLDER, DELIVERY V | |

| 006. | [06] | 09013-60230 | SPRING, DELIVERY V | 15221-51231 |

| 007. | [06] | 90802-20150 | O-RING | 14611-51201 |

| 008. | [06] | 09013-70061 | GASKET, DELIVERY V | 15221-51241 |

| 008. | [06] | 09013-70130 | GASKET, DELIVERY V | 11420-51241 |

| 009. | [06] | 09014-00410 | VALVE SUB-ASSY, IN | 15221-51031 |

| 010. | [06] | 09015-01161 | ELEMENT SUB-ASSY, | 15221-51051 |

| 011. | [06] | 09016-10210 | SLEEVE, PLUNGER CO | 15221-51382 |

| 012. | [06] | 09016-30082 | SEAT, SPRING, UPR | 15221-51271 |

| 013. | [06] | 09016-40170 | SPRING, PUMP PLUNG | 15221-51281 |

| 014. | [06] | 09030-10060 | SEAT, SPRING, LWR | 15021-51291 |

| 015. | [ C] | 09031-10310 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10300 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10280 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10170 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10160 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10140 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10130 | PLATE, TAPPET ADJU | 15221-51491 |

| 015. | [ C] | 09031-10120 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10110 | PLATE, TAPPET ADJU | |

| 015. | [ C] | 09031-10010 | PLATE, TAPPET ADJU | 14109-51301 |

| 016. | [06] | 09017-00170 | TAPPET SUB-ASSY,IN | 15221-51071 |

| 016-001. | [06] | 09017-10022 | TAPPET, INJECTION | 15021-51990 |

| 016-002. | [06] | 09217-60010 | ROLLER, FEED PUMP | 15109-52931 |

| 016-003. | [06] | 09017-60020 | PIN, INJECTION PUM | 15021-51970 |

| 017. | [06] | 09018-30050 | PIN, INJECTION PUM | 14611-51251 |

| 018. | [02] | 09046-70040 | PLATE | 19484-51461 |

| 019. | [01] | 09021-00302 | RACK ASSY, CONTROL | 15601-51061 |

| 020. | [01] | 09007-00012 | PLATE ASSY, ADJUST | 14611-51391 |

| 020. | [01] | 09006-80020 | PLATE, ADJUSTING | 14384-51391 |

| 021. | [05] | 90260-00601 | WASHER, WAVE | 14952-51551 |

| 022. | [05] | 94904-71980 | BOLT, W/WASHER | 15221-91031 |

| 022. | [05] | 94904-80800 | BOLT, WASHER HEAD | |

| 023. | [01] | 09024-50170 | SCREW, HOLLOW | 15471-51321 |

| 026. | [02] | 09022-20050 | WASHER, FUEL PIPE | 15109-51731 |

Include in #3:

09450-04600

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-04600 | 16361-5101 | PUMP ASSY, INJECTI | |

| 16361-51012 | KUBOTA | PUMP ASSY, INJECTI |

Information:

Introduction

This Special Instruction provides information on how to rework the phase change tank on the machines listed above.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Safety Section

Personal injury or death can result from fumes, gases and ultraviolet rays from the weld arc.Welding can cause fumes, burn skin and produce ultraviolet rays.Keep your head out of the fumes. Use ventilation, exhaust at the arc, or both, to keep fumes and gases from your breathing area. Wear eye, ear and body protection before working.Protect yourself and others; read and understand this warning. Fumes and gases can be dangerous to your health. Ultraviolet rays from the weld arc can injure eyes and burn skin. Electric shock can cause death.Read and understand the manufacturer's instructions and your employer's safety practices. Do not touch live electrical parts.See "American National Standard Z49.1, Safety in Welding and Cutting" published by the American Welding Society.American Welding Society

2501 N.W. 7th Street

Miami, Florida 33125

See "OSHA Safety and Health Standards, 29 CFR 1910", available from U.S. Department of Labor.U.S. Department of Labor

Washington, D.C. 20210

Personal injury can result from flame cutting or welding on painted areas.The effect of gasses from burned paint is a hazard to the person doing the cutting or welding.Do not flame cut or weld on painted areas.

Be sure all personnel are clear of equipment while equipment is being lowered.Failure to stay clear may result in personal injury.

Hydraulic oil pressure can remain in the hydraulic systems after the engine and pump have been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic systems. To prevent possible injury, refer to the section, Testing and Adjusting, "Hydraulic System Pressure - Release" before any fitting, hose or component is loosened, tightened, removed or adjusted.When possible, the bucket or attachment must always be lowered to the ground before service is started. When it is necessary for the boom to be in the raised position while tests or adjustments are done, be sure that the boom, stick and bucket or attachment have correct support.The swing lock (if equipped) must be engaged before service is started.Always move the machine to a location away from the travel of other machines. Be sure that other personnel are not near the machine when the engine is running and tests or adjustments are being made.

Personal injury can result from hydraulic oil pressure and hot oil.Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system.Make sure all of the work tools have been lowered to the ground, and the oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand.

Accidental engine starting can cause injury or death to personnel

This Special Instruction provides information on how to rework the phase change tank on the machines listed above.Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.Safety Section

Personal injury or death can result from fumes, gases and ultraviolet rays from the weld arc.Welding can cause fumes, burn skin and produce ultraviolet rays.Keep your head out of the fumes. Use ventilation, exhaust at the arc, or both, to keep fumes and gases from your breathing area. Wear eye, ear and body protection before working.Protect yourself and others; read and understand this warning. Fumes and gases can be dangerous to your health. Ultraviolet rays from the weld arc can injure eyes and burn skin. Electric shock can cause death.Read and understand the manufacturer's instructions and your employer's safety practices. Do not touch live electrical parts.See "American National Standard Z49.1, Safety in Welding and Cutting" published by the American Welding Society.American Welding Society

2501 N.W. 7th Street

Miami, Florida 33125

See "OSHA Safety and Health Standards, 29 CFR 1910", available from U.S. Department of Labor.U.S. Department of Labor

Washington, D.C. 20210

Personal injury can result from flame cutting or welding on painted areas.The effect of gasses from burned paint is a hazard to the person doing the cutting or welding.Do not flame cut or weld on painted areas.

Be sure all personnel are clear of equipment while equipment is being lowered.Failure to stay clear may result in personal injury.

Hydraulic oil pressure can remain in the hydraulic systems after the engine and pump have been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic systems. To prevent possible injury, refer to the section, Testing and Adjusting, "Hydraulic System Pressure - Release" before any fitting, hose or component is loosened, tightened, removed or adjusted.When possible, the bucket or attachment must always be lowered to the ground before service is started. When it is necessary for the boom to be in the raised position while tests or adjustments are done, be sure that the boom, stick and bucket or attachment have correct support.The swing lock (if equipped) must be engaged before service is started.Always move the machine to a location away from the travel of other machines. Be sure that other personnel are not near the machine when the engine is running and tests or adjustments are being made.

Personal injury can result from hydraulic oil pressure and hot oil.Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system.Make sure all of the work tools have been lowered to the ground, and the oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand.

Accidental engine starting can cause injury or death to personnel