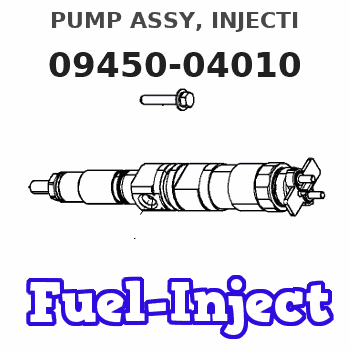

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-04010 |

Scheme ###:

| 000. | [01] | 09450-04010 | PUMP ASSY, INJECTI | 11231-51011 |

| 001. | [01] | 09011-02300 | HOUSING SUB-ASSY, | 14287-51081 |

| 002. | [01] | 09013-10280 | HOLDER, DELIVERY V | 15601-51221 |

| 002. | [01] | 09013-10520 | HOLDER, DELIVERY V | |

| 003. | [01] | 09013-60230 | SPRING, DELIVERY V | 15221-51231 |

| 004. | [01] | 09013-70130 | GASKET, DELIVERY V | 11420-51241 |

| 005. | [01] | 09014-00410 | VALVE SUB-ASSY, IN | 15221-51031 |

| 006. | [01] | 09015-03690 | ELEMENT SUB-ASSY, | |

| 008. | [01] | 09016-30082 | SEAT, SPRING, UPR | 15221-51271 |

| 009. | [01] | 09016-40170 | SPRING, PUMP PLUNG | 15221-51281 |

| 010. | [01] | 09016-10210 | SLEEVE, PLUNGER CO | 15221-51382 |

| 011. | [01] | 09017-00170 | TAPPET SUB-ASSY,IN | 15221-51071 |

| 011-001. | [01] | 09017-10022 | TAPPET, INJECTION | 15021-51990 |

| 011-002. | [01] | 09217-60010 | ROLLER, FEED PUMP | 15109-52931 |

| 011-003. | [01] | 09017-60020 | PIN, INJECTION PUM | 15021-51970 |

| 012. | [01] | 09021-00342 | RACK ASSY, CONTROL | 14911-51061 |

| 015. | [01] | 94918-00610 | SCREW, HOLLOW | 14911-51321 |

| 016. | [02] | 09024-10010 | WASHER, AIR BLEEDE | 15221-96651 |

| 017. | [01] | 09018-30041 | PIN, INJECTION PUM | 15221-51251 |

| 017. | [01] | 09018-30130 | PIN, INJECTION PUM | |

| 018. | [01] | 09030-10060 | SEAT, SPRING, LWR | 15021-51291 |

| 019. | [01] | 94907-20830 | RING, SNAP | 14911-51431 |

| 020. | [01] | 09013-90410 | O-RING | |

| 020. | [01] | 90802-20150 | O-RING | 14611-51201 |

| 022. | [ C] | 09031-10300 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10280 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10170 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10160 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10140 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10130 | PLATE, TAPPET ADJU | 15221-51491 |

| 022. | [ C] | 09031-10120 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10110 | PLATE, TAPPET ADJU | |

| 022. | [ C] | 09031-10010 | PLATE, TAPPET ADJU | 14109-51301 |

| 022. | [ C] | 09031-10310 | PLATE, TAPPET ADJU |

Include in #3:

09450-04010

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-04010 | 11231-5101 | PUMP ASSY, INJECTI | |

| 11231-51011 | KUBOTA | PUMP ASSY, INJECTI |

Information:

Never add acid or electrolyte.

CLEANING BATTERY: Mix a weak solution of baking soda and water. Be careful not to get cleaning solution into battery. Apply the solution with a soft bristle brush.

CLEANING BATTERY TERMINALSThoroughly rinse the battery and battery tray with clean water. Apply grease to the battery cable clamps and terminals and to all threads. Testing The Electrolyte Solution: The general condition of a battery can be determined by measuring the specific gravity of the electrolyte solution and adjusting the reading to 80°F (27°C). If the electrolyte level is too low to allow taking a hydrometer reading, add make-up water to the correct level and then charge the battery 2 to 4 hours before taking a reading.

TESTING ELECTROLYTE SOLUTION1. Insert the hydrometer into a cell. Fill the hydrometer barrel while holding it vertically. The float must not drag on the wall of the barrel.2. Read the hydrometer: 1.250 or above - fully charged battery cell1.250-1.225 - full to half charged battery cell1.225-1.150 - half to low charged battery cellBelow 1.150 - dead cell1.000 - water3. Test each cell in the same manner.4. If there is more than .050 (50 gravity points) variation between the highest and lowest reading, the battery may need to be replaced.5. Adjust the readings to 80°F (27°C). a. For every 10F° (5.5C°) the electrolyte temperature is above 80°F (27°C), add .004 (4 gravity points) to the specific gravity readings.b. For every 10F°(5.5C°) the electrolyte temperature is below 80°F (27°C), subtract .004 (4 gravity points) from the specific gravity reading.The corrected reading is of most importance during cold weather when the hydrometer reading is always corrected to a lower specific gravity reading. A low reading signifies the battery has less available power to crank the engine and that booster batteries may be required. Voltage Test (After Load): A load test should be made on a battery that discharges very rapidly when in use. To do this apply a resistance of three times the ampere/hour rating of the battery across the battery main terminals. Allow the resistance to discharge the battery for 15 seconds and immediately test the battery voltage. A 6 volt battery in good condition will test 4.5 volts; a 12 volt battery in good condition will test 9 volts and a 24 volt battery will test 18 volts.Use a D.C. voltmeter to locate starting system components which do not function.Solenoid Check

Turn the key switch to START. Starting motor solenoid operation is audible as the starter motor pinion engages with the ring gear on the engine flywheel. The solenoid operation should also close the electric circuit to the starting motor.Starting Motor Circuit Check

Attach one voltmeter lead to the solenoid terminal that is connected to the starting motor. Ground the other lead. Turn the key switch to START and observe the voltmeter. A battery voltage reading indicates the malfunction is in the starting motor. It must be removed for further testing. No voltmeter reading indicates that the solenoid contacts do not close. The solenoid