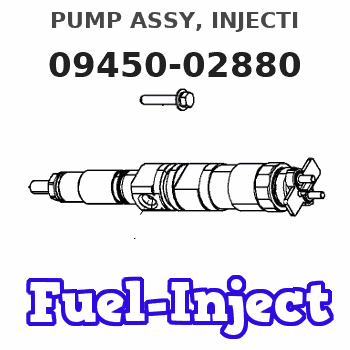

Information pump assy, injecti

Nozzle:

0935001660

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-02880 |

Scheme ###:

| 000. | [01] | 09450-02880 | PUMP ASSY, INJECTI | MM409278 |

| 005. | [01] | 09011-02590 | HOUSING SUB-ASSY, | |

| 006. | [03] | 09013-10520 | HOLDER, DELIVERY V | |

| 007. | [03] | 09013-60540 | SPRING, DELIVERY V | |

| 008. | [03] | 09013-70061 | GASKET, DELIVERY V | MM500336 |

| 008. | [03] | 09013-70130 | GASKET, DELIVERY V | |

| 009. | [03] | 09014-00410 | VALVE SUB-ASSY, IN | 09014-00410 |

| 010. | [03] | 09015-02040 | ELEMENT SUB-ASSY, | |

| 011. | [03] | 09016-10210 | SLEEVE, PLUNGER CO | |

| 012. | [03] | 09016-30082 | SEAT, SPRING, UPR | MM501098 |

| 013. | [03] | 09016-40170 | SPRING, PUMP PLUNG | |

| 014. | [03] | 09017-00170 | TAPPET SUB-ASSY,IN | EZ01775027 |

| 014-001. | [03] | 09017-10022 | TAPPET, INJECTION | |

| 014-002. | [03] | 09217-60010 | ROLLER, FEED PUMP | 09217-60010 |

| 014-003. | [03] | 09017-60020 | PIN, INJECTION PUM | |

| 015. | [03] | 09018-30050 | PIN, INJECTION PUM | |

| 016. | [01] | 09021-00470 | RACK ASSY, CONTROL | |

| 017. | [03] | 09030-10060 | SEAT, SPRING, LWR | EZ0177514 |

| 018. | [01] | 09046-70040 | PLATE | |

| 019. | [ C] | 09031-10310 | PLATE, TAPPET ADJU | |

| 019. | [ C] | 09031-10300 | PLATE, TAPPET ADJU | |

| 019. | [ C] | 09031-10280 | PLATE, TAPPET ADJU | |

| 019. | [ C] | 09031-10170 | PLATE, TAPPET ADJU | FR51530028 |

| 019. | [ C] | 09031-10160 | PLATE, TAPPET ADJU | FR51530027 |

| 019. | [ C] | 09031-10140 | PLATE, TAPPET ADJU | 09031-10140 |

| 019. | [ C] | 09031-10130 | PLATE, TAPPET ADJU | 09031-10130 |

| 019. | [ C] | 09031-10120 | PLATE, TAPPET ADJU | 09031-10120 |

| 019. | [ C] | 09031-10110 | PLATE, TAPPET ADJU | 09031-10110 |

| 019. | [ C] | 09031-10010 | PLATE, TAPPET ADJU | 09031-10010 |

| 020. | [01] | 09022-20080 | WASHER, FUEL PIPE | MM500114 |

| 020. | [01] | 94901-81020 | WASHER, COPPER PLA | 94901-81020 |

| 021. | [01] | 09024-40180 | SCREW, AIR BLEEDER | |

| 022. | [01] | 09024-50210 | SCREW, HOLLOW | |

| 023. | [02] | 09007-00012 | PLATE ASSY, ADJUST | 09007-00012 |

| 023. | [02] | 09006-80020 | PLATE, ADJUSTING | |

| 024. | [02] | 94904-71980 | BOLT, W/WASHER | |

| 024. | [02] | 94904-80800 | BOLT, WASHER HEAD | MM514195 |

| 025. | [01] | 09055-40300 | SPRING, DIAPHRAGM | |

| 026. | [01] | 09055-40160 | SPRING, DIAPHRAGM | |

| 027. | [03] | 90802-20150 | O-RING | |

| 028. | [01] | 09089-40020 | E-RING | 09089-40020 |

| 029. | [01] | 09089-40010 | E-RING | 09089-40010 |

| 032. | [ C] | 09021-92540 | STOPPER | |

| 032. | [ C] | 09021-92530 | STOPPER | |

| 032. | [ C] | 09021-92520 | STOPPER | |

| 032. | [ C] | 09021-92510 | STOPPER | |

| 032. | [ C] | 09021-92500 | STOPPER | |

| 033. | [ C] | 09021-93640 | STOPPER | |

| 033. | [ C] | 09021-93620 | STOPPER | |

| 033. | [ C] | 09021-93600 | STOPPER | |

| 033. | [ C] | 09021-93580 | STOPPER | |

| 033. | [ C] | 09021-93560 | STOPPER | |

| 033. | [ C] | 09021-93540 | STOPPER | |

| 033. | [ C] | 09021-93520 | STOPPER | |

| 033. | [ C] | 09021-93500 | STOPPER | |

| 033. | [ C] | 09021-93480 | STOPPER | |

| 033. | [ C] | 09021-93660 | STOPPER |

Include in #3:

09450-02880

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-02880 | MM409278 | PUMP ASSY, INJECTI | |

| MM409278 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

4C6090 Temp. Selector GPProblem:

We have received reports, (also from 3400E HEUI Engines), about difficulties to pin-point "faulty" injectors with the help of ET. This is especially the case, if a cylinder is not completely "cold". Fortunately, we have a second, very effective tool/method, to quickly find "faulty" injectors for 3500 Series Engines. This tool does not replace ET, it complements ET (ET = Electronic Technician).Solution:

The solution is the 4C6090 Multi Channel Temperature Selector Gp, to measure & compare individual cylinder temperatures. This is a fairly inexpensive, but if used correctly, a highly effective tool (those of you, who have worked already on Marine Engines, may agree). Caution: Read also the chapter: "Cold Cylinder Cut-Out" in the Service Manual, before running this test. Test procedure: AAInstall the tool and the 4C6093 1-8 channel cable pack (for 12 & 16 cylinder Engines you need to order a second 8 channel cable pack) on the "cold" Engine. Check all 7E6830 thermocouples. Replace as necessary. Write down all "cold" individual cylinder and the ambient temperature(s). Caution: Each multi channel temperature test is: Engine, site, test individual! BBStart the Engine & let it warm up at LI: do not read any individual cylinder temperatures until you are 100% sure that all Engine temperatures have stabilized ! (LI = Low Idle) Write down the LI individual cylinder temperatures on the same chart as above. CCSelect Engine HI. - Read all individual cylinder temperatures, once the temperatures have stabilized ! Caution: On Engines with thermostatically controlled SCAC systems, your test may get fouled up by a sudden inrush of "cold" coolant, when the SCAC thermostats open ! (HI = High Idle, SCAC = Separate Circuit After Cooler) Write down the HI individual Engine cylinder temperatures on the same chart. DDThe Tool Operating Manual also discusses to do this test in Torque Converter Stall Conditions. If you manage to do this without "grilling" the TC and/or the Oil, by all means, give it a try. The importance is to get good, valid data, that allows you to make a decision about yes or no for possible injector replacement. Go, no-go tolerance band for possibly "good/faulty" injectors.For each test (Cold, LI, HI, & maybe TC-Stall) take all individual cylinder temperatures and add them up. Then, divide this figure by the number of cylinders (for the 992G, that would be 8). This is your average 0-Line, or, averaged cylinder temperatures. Example: Say, at High Idle you find for no. 1 to 8 cylinders: 736F, 701F, 756F, 695F, 728F, 714F, 682F, 732F. - Hence, your 0-line would be: 718 Deg F. This 0-Line has to be re-established for each test, each Engine, each Site, every time you run/re-run this test ! From the 0-Line, the tolerance band is plus/minus 42 degrees C (75 Deg F). I.e. any cylinder that falls outside the tolerance band of a total of 84 degrees C. (150 Deg F), needs further investigation, and possibly an injector replacement.As per the example above,

We have received reports, (also from 3400E HEUI Engines), about difficulties to pin-point "faulty" injectors with the help of ET. This is especially the case, if a cylinder is not completely "cold". Fortunately, we have a second, very effective tool/method, to quickly find "faulty" injectors for 3500 Series Engines. This tool does not replace ET, it complements ET (ET = Electronic Technician).Solution:

The solution is the 4C6090 Multi Channel Temperature Selector Gp, to measure & compare individual cylinder temperatures. This is a fairly inexpensive, but if used correctly, a highly effective tool (those of you, who have worked already on Marine Engines, may agree). Caution: Read also the chapter: "Cold Cylinder Cut-Out" in the Service Manual, before running this test. Test procedure: AAInstall the tool and the 4C6093 1-8 channel cable pack (for 12 & 16 cylinder Engines you need to order a second 8 channel cable pack) on the "cold" Engine. Check all 7E6830 thermocouples. Replace as necessary. Write down all "cold" individual cylinder and the ambient temperature(s). Caution: Each multi channel temperature test is: Engine, site, test individual! BBStart the Engine & let it warm up at LI: do not read any individual cylinder temperatures until you are 100% sure that all Engine temperatures have stabilized ! (LI = Low Idle) Write down the LI individual cylinder temperatures on the same chart as above. CCSelect Engine HI. - Read all individual cylinder temperatures, once the temperatures have stabilized ! Caution: On Engines with thermostatically controlled SCAC systems, your test may get fouled up by a sudden inrush of "cold" coolant, when the SCAC thermostats open ! (HI = High Idle, SCAC = Separate Circuit After Cooler) Write down the HI individual Engine cylinder temperatures on the same chart. DDThe Tool Operating Manual also discusses to do this test in Torque Converter Stall Conditions. If you manage to do this without "grilling" the TC and/or the Oil, by all means, give it a try. The importance is to get good, valid data, that allows you to make a decision about yes or no for possible injector replacement. Go, no-go tolerance band for possibly "good/faulty" injectors.For each test (Cold, LI, HI, & maybe TC-Stall) take all individual cylinder temperatures and add them up. Then, divide this figure by the number of cylinders (for the 992G, that would be 8). This is your average 0-Line, or, averaged cylinder temperatures. Example: Say, at High Idle you find for no. 1 to 8 cylinders: 736F, 701F, 756F, 695F, 728F, 714F, 682F, 732F. - Hence, your 0-line would be: 718 Deg F. This 0-Line has to be re-established for each test, each Engine, each Site, every time you run/re-run this test ! From the 0-Line, the tolerance band is plus/minus 42 degrees C (75 Deg F). I.e. any cylinder that falls outside the tolerance band of a total of 84 degrees C. (150 Deg F), needs further investigation, and possibly an injector replacement.As per the example above,