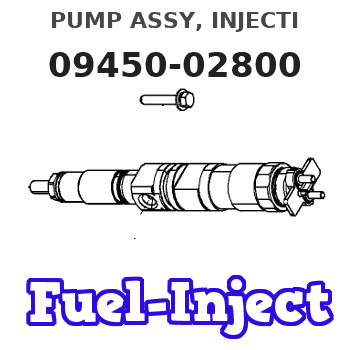

Information pump assy, injecti

PUMP ASSY, INJECTI

ZC

- *1 THE SET PART (090691-1020 AND 090183-0090) IS

- INTERCHANGEABLE WITH 090691-0840.

Nozzle:

0935002510

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-02800 |

| 001. | PUMP ASSY, INJECTI | 09450-02800 |

Scheme ###:

| 000. | [01] | 09450-02800 | PUMP ASSY, INJECTI | 131017160 |

| 000. | [01] | 09450-02800 | PUMP ASSY, INJECTI | 131017161 |

| 003. | [01] | 09011-03060 | HOUSING SUB-ASSY, | 131316050 |

| 004. | [03] | 09013-10830 | HOLDER, DELIVERY V | 131196120 |

| 005. | [03] | 09013-60530 | SPRING, DELIVERY V | 131176430 |

| 006. | [03] | 09013-70130 | GASKET, DELIVERY V | 131186050 |

| 007. | [03] | 09014-01360 | VALVE SUB-ASSY, IN | 131156110 |

| 008. | [03] | 09015-03220 | ELEMENT SUB-ASSY, | 131116371 |

| 009. | [03] | 09016-00140 | SLEEVE SUB-ASSY, C | 131296950 |

| 010. | [03] | 09016-30140 | SEAT, SPRING, UPR | 131296620 |

| 011. | [03] | 09016-40220 | SPRING, PUMP PLUNG | 131176440 |

| 012. | [03] | 09016-50170 | SEAT, SPRING, LWR | 131296621 |

| 013. | [03] | 09017-00220 | TAPPET SUB-ASSY,IN | 131256120 |

| 014. | [01] | 09021-00500 | RACK ASSY, CONTROL | 131296636 |

| 015. | [01] | 09024-40010 | SCREW, AIR BLEEDER | 131236201 |

| 016. | [01] | 09024-50240 | SCREW, HOLLOW | 131236190 |

| 017. | [01] | 09024-80010 | WASHER, DRAIN SCRE | 131426190 |

| 018. | [02] | 09025-10010 | WASHER, INJECTION | 131426180 |

| 019. | [03] | 09018-30090 | PIN, INJECTION PUM | 131296651 |

| 020. | [02] | 94900-20500 | SCREW, COUNTERSUNK | 131136320 |

| 021. | [01] | 94918-10430 | NIPPLE, SWIVELING | 131246130 |

| 022. | [01] | 09069-10840 | BRACKET, STOP WIRE | 131296637 |

| 022. | [01] | 09069-11020 | BRACKET, STOP WIRE | 131296650 |

| 023. | [03] | 90801-10130 | O-RING | 131226170 |

| 023. | [03] | 09013-90400 | O-RING | |

| 024. | [3C] | 09031-10400 | PLATE, TAPPET ADJU | 131296630 |

| 024. | [3C] | 09031-10410 | PLATE, TAPPET ADJU | 131296631 |

| 024. | [3C] | 09031-10420 | PLATE, TAPPET ADJU | 131296632 |

| 024. | [3C] | 09031-10430 | PLATE, TAPPET ADJU | 131296633 |

| 024. | [3C] | 09031-10440 | PLATE, TAPPET ADJU | 131296634 |

| 024. | [3C] | 09031-10390 | PLATE, TAPPET ADJU | 131296629 |

| 024. | [3C] | 09031-10380 | PLATE, TAPPET ADJU | 131296628 |

| 024. | [3C] | 09031-10370 | PLATE, TAPPET ADJU | 131296627 |

| 024. | [3C] | 09031-10360 | PLATE, TAPPET ADJU | 131296626 |

| 024. | [3C] | 09031-10350 | PLATE, TAPPET ADJU | 131296625 |

| 024. | [3C] | 09031-10340 | PLATE, TAPPET ADJU | 131296624 |

| 024. | [3C] | 09031-10330 | PLATE, TAPPET ADJU | 131296623 |

| 024. | [3C] | 09031-10320 | PLATE, TAPPET ADJU | 131296622 |

| 024. | [3C] | 09031-10450 | PLATE, TAPPET ADJU | 131296635 |

Include in #3:

09450-02800

as PUMP ASSY, INJECTI

09450-02800

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-02800 | 131017160 | PUMP ASSY, INJECTI | |

| 131017161 | ISHIKAWAJIMA | PUMP ASSY, INJECTI | |

| 131017160 | ISHIKAWAJIMA | PUMP ASSY, INJECTI |

Information:

aslink" data-element=".content_table_1">

TECHNICAL INFORMATION BULLETIN March 27, 2002

Engines 3516 (25Z, 5SJ, 7KM, CMD, 4XF)

3516B (1HZ, 7RN, 5AN, FDN, BDP,

6HN)

Component Code: 1404SUBJECT: Generator Stator Adapter Cracking on 3516 Diesel Generator Set

PROBLEM:

Certain SR4B single bearing generators may develop cracks in the adapter assembly. The generator adapter is the welded assembly, part of the generator stator, consisting of the front adapter ring that bolts to the flywheel housing and the individual support bars welded to this adapter ring. Several different weld failure modes exist for the generator adapter. First, there may be cracks along the top weld leg between the adapter supports and the front adapter ring. Second, there may be cracks at the toe of the welds joining the adapter support bars to the front ring. These cracks appear in the heat-affected zone of the welds and propagate into the front adapter ring of the generator. The third failure mode is radial cracks between the end ring of the generator adapter and the stator housing. This type of crack most likely occurs after the support welds have failed. After the support welds have failed, the cracks at the toe of the support bars propagate into the ring and create a stress riser.

SOLUTION:

Caterpillar is redesigning the current product and is also working on a solution that will address the existing units in the field. At this time, it is NOT recommended to immediately replace cracked generator stators, nor is it recommended to re-weld the cracked adapters as a field repair. Rather, a crack observation and evaluation process should be established for each individual case. It is anticipated that the first recognizable cracks on suspect generators (cracks size of 0.25" and larger) may appear as early as 300 hours. If any of the above-described cracks are found, the servicing dealer should contact Caterpillar Service. The servicing dealer should also assist in periodic inspection of the cracks in an effort to determine the next action.

Contact (if different from sender): Miro Halicek (770) 233-5877 or Marc Sylvester (770) 233-5630.

COPYRIGHT 2002 CATERPILLAR

ALL RIGHTS RESERVED

TECHNICAL INFORMATION BULLETIN March 27, 2002

Engines 3516 (25Z, 5SJ, 7KM, CMD, 4XF)

3516B (1HZ, 7RN, 5AN, FDN, BDP,

6HN)

Component Code: 1404SUBJECT: Generator Stator Adapter Cracking on 3516 Diesel Generator Set

PROBLEM:

Certain SR4B single bearing generators may develop cracks in the adapter assembly. The generator adapter is the welded assembly, part of the generator stator, consisting of the front adapter ring that bolts to the flywheel housing and the individual support bars welded to this adapter ring. Several different weld failure modes exist for the generator adapter. First, there may be cracks along the top weld leg between the adapter supports and the front adapter ring. Second, there may be cracks at the toe of the welds joining the adapter support bars to the front ring. These cracks appear in the heat-affected zone of the welds and propagate into the front adapter ring of the generator. The third failure mode is radial cracks between the end ring of the generator adapter and the stator housing. This type of crack most likely occurs after the support welds have failed. After the support welds have failed, the cracks at the toe of the support bars propagate into the ring and create a stress riser.

SOLUTION:

Caterpillar is redesigning the current product and is also working on a solution that will address the existing units in the field. At this time, it is NOT recommended to immediately replace cracked generator stators, nor is it recommended to re-weld the cracked adapters as a field repair. Rather, a crack observation and evaluation process should be established for each individual case. It is anticipated that the first recognizable cracks on suspect generators (cracks size of 0.25" and larger) may appear as early as 300 hours. If any of the above-described cracks are found, the servicing dealer should contact Caterpillar Service. The servicing dealer should also assist in periodic inspection of the cracks in an effort to determine the next action.

Contact (if different from sender): Miro Halicek (770) 233-5877 or Marc Sylvester (770) 233-5630.

COPYRIGHT 2002 CATERPILLAR

ALL RIGHTS RESERVED