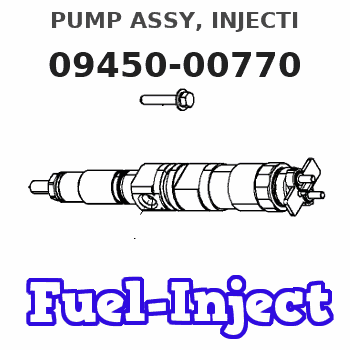

Information pump assy, injecti

Nozzle:

0935001460

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-00770 |

| 001. | PUMP ASSY, INJECTI | 09450-00770 |

Scheme ###:

| 000. | [01] | 09450-00770 | PUMP ASSY, INJECTI | 131016230 |

| 000. | [01] | 09450-00770 | PUMP ASSY, INJECTI | 131016231 |

| 005. | [02] | 09013-10280 | HOLDER, DELIVERY V | 131196050 |

| 005. | [02] | 09013-10520 | HOLDER, DELIVERY V | |

| 006. | [02] | 09013-60230 | SPRING, DELIVERY V | 131176180 |

| 007. | [02] | 90802-20150 | O-RING | 131226070 |

| 007. | [02] | 09013-90410 | O-RING | |

| 008. | [02] | 09013-70130 | GASKET, DELIVERY V | 131186050 |

| 009. | [02] | 09014-00410 | VALVE SUB-ASSY, IN | 131156040 |

| 010. | [02] | 09015-01600 | ELEMENT SUB-ASSY, | 131116100 |

| 011. | [02] | 09016-10210 | SLEEVE, PLUNGER CO | 131296262 |

| 012. | [02] | 09016-30082 | SEAT, SPRING, UPR | 131296529 |

| 013. | [02] | 09016-40170 | SPRING, PUMP PLUNG | 131296264 |

| 014. | [02] | 09030-10060 | SEAT, SPRING, LWR | 131296172 |

| 015. | [2C] | 09031-10310 | PLATE, TAPPET ADJU | |

| 015. | [2C] | 09031-10300 | PLATE, TAPPET ADJU | |

| 015. | [2C] | 09031-10280 | PLATE, TAPPET ADJU | 131296513 |

| 015. | [2C] | 09031-10170 | PLATE, TAPPET ADJU | 131296179 |

| 015. | [2C] | 09031-10160 | PLATE, TAPPET ADJU | 131296178 |

| 015. | [2C] | 09031-10140 | PLATE, TAPPET ADJU | 131296177 |

| 015. | [2C] | 09031-10130 | PLATE, TAPPET ADJU | 131296176 |

| 015. | [2C] | 09031-10120 | PLATE, TAPPET ADJU | 131296175 |

| 015. | [2C] | 09031-10110 | PLATE, TAPPET ADJU | 131296174 |

| 015. | [2C] | 09031-10010 | PLATE, TAPPET ADJU | 131296173 |

| 016. | [01] | 09046-70030 | PLATE | 131296267 |

| 017. | [01] | 09021-00290 | RACK ASSY, CONTROL | |

| 018. | [01] | 09006-80020 | PLATE, ADJUSTING | 131296660 |

| 019. | [01] | 94904-80800 | BOLT, WASHER HEAD | |

| 019. | [01] | 94904-71980 | BOLT, W/WASHER | 131296528 |

| 020. | [01] | 94918-00050 | SCREW, HOLLOW | 131236271 |

| 021. | [02] | 09024-10010 | WASHER, AIR BLEEDE | 131296166 |

| 022. | [02] | 09017-00170 | TAPPET SUB-ASSY,IN | 131256070 |

| 022-001. | [02] | 09017-10021 | TAPPET, INJECTION | 131256080 |

| 022-002. | [02] | 09217-60010 | ROLLER, FEED PUMP | 131296265 |

| 022-003. | [02] | 09017-60020 | PIN, INJECTION PUM | 131296182 |

| 023. | [02] | 09018-30050 | PIN, INJECTION PUM | 131296266 |

| 024. | [01] | 09011-01042 | HOUSING SUB-ASSY, |

Include in #3:

09450-00770

as PUMP ASSY, INJECTI

09450-00770

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-00770 | 131016230 | PUMP ASSY, INJECTI | |

| 131016231 | ISHIKAWAJIMA | PUMP ASSY, INJECTI | |

| 131016230 | ISHIKAWAJIMA | PUMP ASSY, INJECTI |

Information:

Walk-Around Inspection

Perform required Daily and other periodic maintenance before starting the engine. Make a walk-around inspection of the installation. It only takes a few minutes to make minor corrections. This can prevent major repairs at a later date.* For maximum service life of your engine, make a thorough inspection before starting the engine. Look for items such as oil or coolant leaks, loose bolts, and trash build-up. Remove trash build-up and have repairs made as needed.* Inspect the radiator hoses for cracks and loose clamps.* Inspect the fan belts and accessory drive belts for cracks, breaks, and other damage.* Inspect the wiring for loose connections and for worn or frayed wires.* Check the fuel supply. Drain water from the water separator (if equipped). Open the fuel supply valve.

All valves in fuel return line must be open before and during engine operation to prevent high fuel pressure. High fuel pressure may cause filter housing failure or other damage.

If the engine has not been run for several weeks, fuel may have drained and allowed air into the filter housing. Also, when fuel filters have been changed, some air space will be left in the housing. In these instances, prime the fuel system. Refer to Priming the Fuel System in this publication for more information.

Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well-ventilated area and, if in an enclosed area, vent the exhaust to the outside.

* Do not start the engine or move any of the controls if there is a DO NOT OPERATE or similar warning tag attached to the start switch or controls.* The operator must be satisfied that no one will be endangered before starting the engine.* Disconnect the battery charger (if equipped).* Reset any shutoff or alarm components (if equipped): Low Oil Pressure, Overspeed, Air Shutoff.* Check for damaged or missing guards. Repair or replace any damaged or missing guards.

Oil Level Gauge (Dipstick): ENGINE STOPPED side (1), LOW IDLE side (2), ADD mark, and FULL mark.* Check the oil level. The ENGINE STOPPED side of the dipstick is marked to read when the engine is stopped. The LOW IDLE side of the dipstick is marked to read when the engine is at low idle. Maintain the oil level between the ADD and FULL marks.* Check the coolant level. Make sure the engine is cool. Remove the radiator or expansion tank filler cap slowly to relieve any pressure. Maintain the coolant to within 13mm (1/2 inch) of the bottom of the fill pipe.* Observe the air cleaner service indicator (if equipped). Service the air cleaner when the yellow diaphragm enters the red zone, or the red piston locks in the visible position.Starting, Operating and Stopping Engines Equipped with Control Panels

For information regarding the generator control panel used for starting, operating and stopping the engine, refer to Caterpillar SR4B Generators and Control Panels, SEBU6918 or Caterpillar SR4 Generators and Control Panels, SEBU6150. Additional information and

Perform required Daily and other periodic maintenance before starting the engine. Make a walk-around inspection of the installation. It only takes a few minutes to make minor corrections. This can prevent major repairs at a later date.* For maximum service life of your engine, make a thorough inspection before starting the engine. Look for items such as oil or coolant leaks, loose bolts, and trash build-up. Remove trash build-up and have repairs made as needed.* Inspect the radiator hoses for cracks and loose clamps.* Inspect the fan belts and accessory drive belts for cracks, breaks, and other damage.* Inspect the wiring for loose connections and for worn or frayed wires.* Check the fuel supply. Drain water from the water separator (if equipped). Open the fuel supply valve.

All valves in fuel return line must be open before and during engine operation to prevent high fuel pressure. High fuel pressure may cause filter housing failure or other damage.

If the engine has not been run for several weeks, fuel may have drained and allowed air into the filter housing. Also, when fuel filters have been changed, some air space will be left in the housing. In these instances, prime the fuel system. Refer to Priming the Fuel System in this publication for more information.

Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well-ventilated area and, if in an enclosed area, vent the exhaust to the outside.

* Do not start the engine or move any of the controls if there is a DO NOT OPERATE or similar warning tag attached to the start switch or controls.* The operator must be satisfied that no one will be endangered before starting the engine.* Disconnect the battery charger (if equipped).* Reset any shutoff or alarm components (if equipped): Low Oil Pressure, Overspeed, Air Shutoff.* Check for damaged or missing guards. Repair or replace any damaged or missing guards.

Oil Level Gauge (Dipstick): ENGINE STOPPED side (1), LOW IDLE side (2), ADD mark, and FULL mark.* Check the oil level. The ENGINE STOPPED side of the dipstick is marked to read when the engine is stopped. The LOW IDLE side of the dipstick is marked to read when the engine is at low idle. Maintain the oil level between the ADD and FULL marks.* Check the coolant level. Make sure the engine is cool. Remove the radiator or expansion tank filler cap slowly to relieve any pressure. Maintain the coolant to within 13mm (1/2 inch) of the bottom of the fill pipe.* Observe the air cleaner service indicator (if equipped). Service the air cleaner when the yellow diaphragm enters the red zone, or the red piston locks in the visible position.Starting, Operating and Stopping Engines Equipped with Control Panels

For information regarding the generator control panel used for starting, operating and stopping the engine, refer to Caterpillar SR4B Generators and Control Panels, SEBU6918 or Caterpillar SR4 Generators and Control Panels, SEBU6150. Additional information and