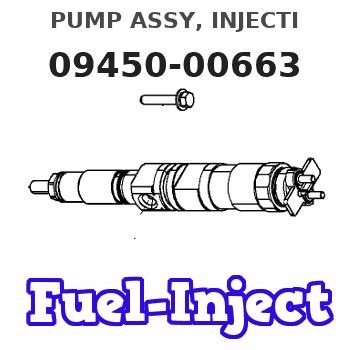

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-00663 |

Scheme ###:

| 000. | [01] | 09450-00663 | PUMP ASSY, INJECTI | FR51530 |

| 005. | [01] | 09013-10300 | HOLDER, DELIVERY V | FR51960005 |

| 006. | [01] | 19011-01431 | HOUSING KIT, INJEC | FR51960006 |

| 007. | [01] | 09013-60080 | SPRING, DELIVERY V | FR51530007 |

| 008. | [01] | 09013-70010 | GASKET, DELIVERY V | 85265-00019 |

| 009. | [01] | 09014-00290 | VALVE SUB-ASSY, IN | FR51530009 |

| 010. | [01] | 09015-01582 | ELEMENT SUB-ASSY, | FR51530010 |

| 011. | [01] | 09016-10200 | SLEEVE, PLUNGER CO | FR51960062 |

| 012. | [01] | 09016-30010 | SEAT, SPRING, UPR | 09016-30010 |

| 013. | [01] | 09016-40010 | SPRING, PUMP PLUNG | 85265-00029 |

| 014. | [01] | 09016-50160 | SEAT, SPRING, LWR | 09016-50160 |

| 015. | [1C] | 09031-10270 | PLATE, TAPPET ADJU | |

| 015. | [1C] | 09031-10260 | PLATE, TAPPET ADJU | |

| 015. | [1C] | 09031-10250 | PLATE, TAPPET ADJU | FR51960072 |

| 015. | [1C] | 09031-10240 | PLATE, TAPPET ADJU | FR51960071 |

| 015. | [1C] | 09031-10230 | PLATE, TAPPET ADJU | FR51960070 |

| 015. | [1C] | 09031-10220 | PLATE, TAPPET ADJU | FR51960069 |

| 015. | [1C] | 09031-10210 | PLATE, TAPPET ADJU | FR51960068 |

| 015. | [1C] | 09031-10200 | PLATE, TAPPET ADJU | FR51960067 |

| 015. | [1C] | 09031-10190 | PLATE, TAPPET ADJU | FR51960066 |

| 016. | [01] | 09017-00160 | TAPPET SUB-ASSY,IN | FR51960073 |

| 017. | [01] | 09018-30060 | PIN, INJECTION PUM | FR51960074 |

| 018. | [01] | 09018-40060 | RING, CLAMP | FR51530031 |

| 019. | [01] | 09021-00270 | RACK ASSY, CONTROL | FR51530032 |

| 020. | [01] | 94901-81020 | WASHER, COPPER PLA | 94901-81020 |

| 020. | [01] | 09022-20080 | WASHER, FUEL PIPE | MM500114 |

| 021. | [01] | 09024-40080 | SCREW, AIR BLEEDER | FR51961063 |

| 022. | [01] | 09024-50012 | SCREW, HOLLOW | FR51530035 |

| 023. | [01] | 09022-30010 | PLATE, PUSH | FR51530043 |

| 024. | [01] | 09055-40040 | SPRING, DIAPHRAGM | FR51530044 |

| 025. | [01] | 90400-16101 | PIN, SPLIT | FR51530045 |

| 026. | [01] | 09007-80013 | COVER | FR51530046 |

| 027. | [1C] | 09021-91440 | STOPPER | FR51960059 |

| 027. | [1C] | 09021-91450 | STOPPER | FR51960060 |

| 027. | [1C] | 09021-91630 | STOPPER | |

| 027. | [1C] | 09021-91640 | STOPPER | |

| 027. | [1C] | 09021-91650 | STOPPER | |

| 027. | [1C] | 09021-91890 | STOPPER | |

| 027. | [1C] | 09021-91900 | STOPPER | |

| 027. | [1C] | 09021-91430 | STOPPER | FR51960058 |

| 027. | [1C] | 09021-91420 | STOPPER | FR51960057 |

| 027. | [1C] | 09021-91340 | STOPPER | FR51960050 |

| 027. | [1C] | 09021-91350 | STOPPER | FR51960051 |

| 027. | [1C] | 09021-91360 | STOPPER | FR51960052 |

| 027. | [1C] | 09021-91370 | STOPPER | FR51960053 |

| 027. | [1C] | 09021-91380 | STOPPER | FR51960054 |

| 027. | [1C] | 09021-91390 | STOPPER | FR51960055 |

| 027. | [1C] | 09021-91400 | STOPPER | FR51960056 |

| 028. | [02] | 09024-10010 | WASHER, AIR BLEEDE | MM500486 |

| 032. | [01] | 94918-00050 | SCREW, HOLLOW | 34061-06200 |

Include in #3:

09450-00663

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-00663 | FR51530 | PUMP ASSY, INJECTI |

Information:

Walk-Around Inspection

Inspect Engine for Leaks and Loose Connections

A walk-around inspection should only take a few minutes of your time. By taking the time to make these checks, costly repairs and accidents can be avoided and your equipment will be ready to run should the need arise.For maximum engine service life, make a thorough inspection before starting the engine. Look for items such as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected: check the fluid levels more frequently than the recommended maintenance intervals and continue to monitor fluid levels until any leak is found and fixed.* Wipe all fittings, caps and plugs before servicing to reduce the chance of system contamination. Inspect:* Radiator core for leaks and trash build-up.* Radiator and air inlet system hoses and elbows for cracks and loose clamps.* air-to-air aftercooler for insects, dirt and other debris. Clean as necessary. Clean the front of the aftercooler with a stainless steel brush and soapy water.Depending on your findings and operating environment, the maintenance interval for cleaning the air-to-air aftercooler can be extended from a Daily to an as needed basis.* Fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break.* Water pump for coolant leaks at weep hole. Check weep hole for water pump breather filter blockage. Replace the filter if necessary. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract.If leaks are found, check the coolant level frequently and continue to monitor the level until the water pump is repaired. Excessive coolant leakage may indicate the need to replace the water pump seal. For removal and installation of water pumps and/or seals, see the Service Manual for this engine or consult your Caterpillar dealer.* Lube system for leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers.* Fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses.

Fuel line clamps should not be over torqued. Over torqueing causes the clamps to butterfly, which results in low clamping force, fuel line vibration and eventual failure. Refer to the Torque Specifications in this manual.

* Drain water and sediment from fuel storage and day tanks on a daily basis to ensure only clean fuel enters the fuel system.* Inspect wiring and wiring harnesses for loose connections and worn or frayed wires. * All guards must be in place. Repair

Inspect Engine for Leaks and Loose Connections

A walk-around inspection should only take a few minutes of your time. By taking the time to make these checks, costly repairs and accidents can be avoided and your equipment will be ready to run should the need arise.For maximum engine service life, make a thorough inspection before starting the engine. Look for items such as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected: check the fluid levels more frequently than the recommended maintenance intervals and continue to monitor fluid levels until any leak is found and fixed.* Wipe all fittings, caps and plugs before servicing to reduce the chance of system contamination. Inspect:* Radiator core for leaks and trash build-up.* Radiator and air inlet system hoses and elbows for cracks and loose clamps.* air-to-air aftercooler for insects, dirt and other debris. Clean as necessary. Clean the front of the aftercooler with a stainless steel brush and soapy water.Depending on your findings and operating environment, the maintenance interval for cleaning the air-to-air aftercooler can be extended from a Daily to an as needed basis.* Fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break.* Water pump for coolant leaks at weep hole. Check weep hole for water pump breather filter blockage. Replace the filter if necessary. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract.If leaks are found, check the coolant level frequently and continue to monitor the level until the water pump is repaired. Excessive coolant leakage may indicate the need to replace the water pump seal. For removal and installation of water pumps and/or seals, see the Service Manual for this engine or consult your Caterpillar dealer.* Lube system for leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers.* Fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses.

Fuel line clamps should not be over torqued. Over torqueing causes the clamps to butterfly, which results in low clamping force, fuel line vibration and eventual failure. Refer to the Torque Specifications in this manual.

* Drain water and sediment from fuel storage and day tanks on a daily basis to ensure only clean fuel enters the fuel system.* Inspect wiring and wiring harnesses for loose connections and worn or frayed wires. * All guards must be in place. Repair