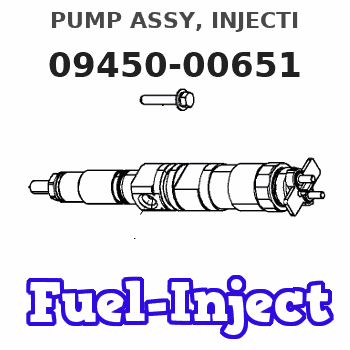

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09450-00651 |

Scheme ###:

| 000. | [01] | 09450-00651 | PUMP ASSY, INJECTI | K9641011 |

| 005. | [01] | 19011-01230 | HOUSING KIT, INJEC | MM500444 |

| 006. | [01] | 09005-90030 | NIPPLE, DELIVERY V | MM500324 |

| 007. | [02] | 09005-80040 | WASHER, NIPPLE | MM500323 |

| 008. | [01] | 09024-50071 | SCREW, HOLLOW | MM500404 |

| 009. | [01] | 09013-10080 | HOLDER, DELIVERY V | MM500329 |

| 010. | [01] | 09013-60080 | SPRING, DELIVERY V | MM500331 |

| 011. | [01] | 09013-70020 | GASKET, DELIVERY V | MM500335 |

| 012. | [01] | 09014-00540 | VALVE SUB-ASSY, IN | MM500341 |

| 013. | [01] | 09015-01321 | ELEMENT SUB-ASSY, | MM500936 |

| 014. | [01] | 09016-10110 | SLEEVE, PLUNGER CO | MM500352 |

| 015. | [01] | 09016-10230 | SLEEVE, PLUNGER CO | MM500351 |

| 016. | [01] | 09016-30080 | SEAT, SPRING, UPR | MM501098 |

| 017. | [01] | 09016-40041 | SPRING, PUMP PLUNG | EZ01775013 |

| 018. | [01] | 09015-60021 | PINION, PLUNGER CO | 09015-60020 |

| 019. | [01] | 09015-70010 | SCREW, PLUNGER CON | ME702059 |

| 020. | [1C] | 09031-10170 | PLATE, TAPPET ADJU | P760-15160 |

| 020. | [1C] | 09031-10160 | PLATE, TAPPET ADJU | MM500314 |

| 020. | [1C] | 09031-10150 | PLATE, TAPPET ADJU | MM500313 |

| 020. | [1C] | 09031-10140 | PLATE, TAPPET ADJU | MM500312 |

| 020. | [1C] | 09031-10130 | PLATE, TAPPET ADJU | MM500311 |

| 020. | [1C] | 09031-10120 | PLATE, TAPPET ADJU | MM500310 |

| 020. | [1C] | 09031-10110 | PLATE, TAPPET ADJU | MM500309 |

| 020. | [1C] | 09031-10010 | PLATE, TAPPET ADJU | ME702559 |

| 021. | [02] | 09030-10060 | SEAT, SPRING, LWR | MM500316 |

| 022. | [02] | 09017-00170 | TAPPET SUB-ASSY,IN | MM500230 |

| 022-001. | [02] | 09017-10022 | TAPPET, INJECTION | |

| 022-002. | [02] | 09017-60020 | PIN, INJECTION PUM | P720-1429 |

| 022-003. | [02] | 09217-60010 | ROLLER, FEED PUMP | ME702227 |

| 023. | [02] | 09018-30010 | PIN, INJECTION PUM | MM500368 |

| 024. | [01] | 09018-50010 | PIN, CLAMP | MM500372 |

| 025. | [01] | 09021-00132 | RACK ASSY, CONTROL | MM500191 |

| 026. | [01] | 94901-81020 | WASHER, COPPER PLA | ME022309 |

| 027. | [01] | 09024-40080 | SCREW, AIR BLEEDER | EZ01775022 |

| 028. | [01] | 94918-00510 | SCREW, HOLLOW | MM500446 |

| 029. | [1C] | 09021-91070 | STOPPER | MM500120 |

| 029. | [1C] | 09021-91060 | STOPPER | MM500119 |

| 029. | [1C] | 09021-91050 | STOPPER | MM500118 |

| 029. | [1C] | 09021-91040 | STOPPER | MM500081 |

| 029. | [1C] | 09021-91030 | STOPPER | MM500080 |

| 029. | [1C] | 09021-91020 | STOPPER | MM500079 |

| 029. | [1C] | 09021-91010 | STOPPER | MM500078 |

| 029. | [1C] | 09021-91000 | STOPPER | MM500077 |

| 029. | [1C] | 09021-90990 | STOPPER | MM500076 |

| 029. | [1C] | 09021-90980 | STOPPER | MM500075 |

| 030. | [01] | 09022-30010 | PLATE, PUSH | MM500401 |

| 031. | [01] | 09055-40060 | SPRING, DIAPHRAGM | MM500407 |

| 034. | [01] | 09007-80013 | COVER | MM500365 |

| 035. | [01] | 94904-10650 | BOLT, SLOTTED HEXA | MM500433 |

| 037. | [01] | 09009-60010 | COVER | MM500325 |

Include in #3:

09450-00651

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09450-00651 | K9641011 | PUMP ASSY, INJECTI |

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Clutch - Check/Adjust/Lubricate Air Starter & Air Tank (if equipped) - Check Engine Air Cleaner - Check service indicator SR4 Generator - Inspect/CheckEvery 1,900 L (500 gal) of Fuel or 50 Service Hours*

Dust Collector - Clean Light Duty Air Cleaner (If Equipped) - ReplaceEvery 4,250 L (1,100 gal) of Fuel or 125 Service Hours*

Clutch - Check/Adjust/Lubricate Generator Space Heaters - CheckEvery 8,500 L (2,200 gal) of Fuel or 250 Service Hours*

Scheduled Oil Sampling (S O S)1 - Obtain Sample Engine Oil and Filter(s)1 - Change Crankcase Breather1 - Clean Engine Valve Lash (Between First 250 and 1000 Service Hours Only)1 - Check/Adjust Cooling System - Test for supplemental coolant additive concentration Fuel System - Clean/Replace filters, Drain water from fuel tank Radiator Fins, Aftercooler, Belts, and Hoses - Inspect/Check Fan Drive Bearing - Lubricate Batteries - Clean/Check Magnetic Pickup (At First Oil Change Only - Inspect/Clean1These maintenance requirements are to be performed between the 250 and the 1000 Service Hour interval for engines equipped with turbochargers (T, TA & ATAAC) ONLY. Refer to 500 Hour interval for Naturally Aspirated (NA) Engines.Every 17,000 L (4,500 gal) of Fuel or 500 Service Hours (NA Only)*

Scheduled Oil Sampling (S O S) - Obtain Sample Engine Oil and Filter(s) - Change Crankcase Breather - Clean Engine Valve Lash (Between First 500 and 1000 Service Hours Only) - Check/AdjustEvery 34,000 L (9,000 gal) of Fuel or 1000 Service Hours*

Engine Protection Devices - Inspect SR4 Generator and Control Panel - Inspect Fuel Control Linkage - LubricateEvery 67,000 L (18,000 gal) of Fuel or 2000 Service Hours*

Engine Valve Lash, Valve Rotators, Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust Fuel Injection Nozzles - Test/Clean/Replace Turbocharger - Inspect Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect SR4 Generator - Check/Inspect Clean/LubricateEvery 91,000 L (24,000 gal) of Fuel or 3000 Service Hours or Two Years*

Cooling System - Add Extender (Extended Life Coolant Only) - Cooling System - Drain/Clean/Replace Coolant - Conventional Coolant/Antifreeze Only Water Pump Seal - Inspect/Replace Hoses - Replace Thermostat - ReplaceEvery 136,000 L (36,000 gal) of Fuel or 4000 Service Hours*

Magnetic Pickup - Inspect/Clean SR4 Generator - Check/Inspect/Clean/LubricateEvery 204,000 L (54,000 gal) of Fuel or 6,000 Service Hours or Four Years

Cooling System - Drain/Flush/Replace Coolant (Extended Life Coolant Only)*Perform previous maintenance interval items first.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Clutch - Check/Adjust/Lubricate Air Starter & Air Tank (if equipped) - Check Engine Air Cleaner - Check service indicator SR4 Generator - Inspect/CheckEvery 1,900 L (500 gal) of Fuel or 50 Service Hours*

Dust Collector - Clean Light Duty Air Cleaner (If Equipped) - ReplaceEvery 4,250 L (1,100 gal) of Fuel or 125 Service Hours*

Clutch - Check/Adjust/Lubricate Generator Space Heaters - CheckEvery 8,500 L (2,200 gal) of Fuel or 250 Service Hours*

Scheduled Oil Sampling (S O S)1 - Obtain Sample Engine Oil and Filter(s)1 - Change Crankcase Breather1 - Clean Engine Valve Lash (Between First 250 and 1000 Service Hours Only)1 - Check/Adjust Cooling System - Test for supplemental coolant additive concentration Fuel System - Clean/Replace filters, Drain water from fuel tank Radiator Fins, Aftercooler, Belts, and Hoses - Inspect/Check Fan Drive Bearing - Lubricate Batteries - Clean/Check Magnetic Pickup (At First Oil Change Only - Inspect/Clean1These maintenance requirements are to be performed between the 250 and the 1000 Service Hour interval for engines equipped with turbochargers (T, TA & ATAAC) ONLY. Refer to 500 Hour interval for Naturally Aspirated (NA) Engines.Every 17,000 L (4,500 gal) of Fuel or 500 Service Hours (NA Only)*

Scheduled Oil Sampling (S O S) - Obtain Sample Engine Oil and Filter(s) - Change Crankcase Breather - Clean Engine Valve Lash (Between First 500 and 1000 Service Hours Only) - Check/AdjustEvery 34,000 L (9,000 gal) of Fuel or 1000 Service Hours*

Engine Protection Devices - Inspect SR4 Generator and Control Panel - Inspect Fuel Control Linkage - LubricateEvery 67,000 L (18,000 gal) of Fuel or 2000 Service Hours*

Engine Valve Lash, Valve Rotators, Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust Fuel Injection Nozzles - Test/Clean/Replace Turbocharger - Inspect Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect SR4 Generator - Check/Inspect Clean/LubricateEvery 91,000 L (24,000 gal) of Fuel or 3000 Service Hours or Two Years*

Cooling System - Add Extender (Extended Life Coolant Only) - Cooling System - Drain/Clean/Replace Coolant - Conventional Coolant/Antifreeze Only Water Pump Seal - Inspect/Replace Hoses - Replace Thermostat - ReplaceEvery 136,000 L (36,000 gal) of Fuel or 4000 Service Hours*

Magnetic Pickup - Inspect/Clean SR4 Generator - Check/Inspect/Clean/LubricateEvery 204,000 L (54,000 gal) of Fuel or 6,000 Service Hours or Four Years

Cooling System - Drain/Flush/Replace Coolant (Extended Life Coolant Only)*Perform previous maintenance interval items first.