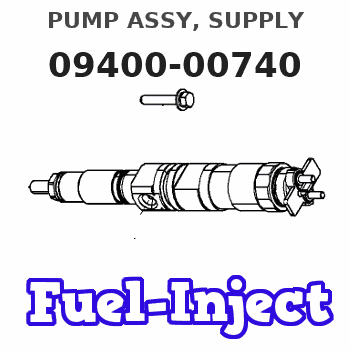

Information pump assy, supply

Rating:

KIT List:

| Pump assy, supply | 0940400010 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Oil Pump Model:094000-0741 22100-E0380 094000-0740 Compatible With Hino E13C Engine

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

Diesel Injection Pump 094000-0741 22100-E0380 094000-0740 Compatible With Hino E13C Engine

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WZCNLXLX 24T Fuel Injection Pump 22100-E0380 094000-0740 22100E0380 0940000740 For Hino E13C Engine

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:22100-E0380 094000-0740 22100E0380 0940000740 || Application:For Hino E13C Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:22100-E0380 094000-0740 22100E0380 0940000740 || Application:For Hino E13C Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

You can express buy:

Components :

| 001. | PUMP ASSY, SUPPLY | 09400-00740 |

| 002. | OVERHAUL KIT, SUPP | 09404-00010 |

| 003. | BODY ASSY, SUPPLY | 09410-00610 |

| 004. | PUMP ASSY, FUEL FE | 09420-00310 |

Scheme ###:

| 000. | [01] | 09400-00740 | PUMP ASSY, SUPPLY | 22100-E0380 |

| 000-001. | [01] | 09404-00010 | OVERHAUL KIT, SUPP | |

| 003. | [01] | 09410-00610 | BODY ASSY, SUPPLY | |

| 004. | [01] | 09420-00310 | PUMP ASSY, FUEL FE | |

| 005. | [01] | 94904-43320 | BOLT | S2281-52070-A |

| 006. | [04] | 09644-90070 | BOLT, SOCKET |

Include in #3:

09400-00740

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09400-00740 | 22100-E038 | PUMP ASSY, SUPPLY | |

| 22100-E0380 | HINO | PUMP ASSY, SUPPLY |

Information:

Remove And Install Crankshaft Main Bearings

Start By:a. remove engine and transmissionb. remove oil pumpc. remove crankshaft rear seal 1. Fasten the engine to tool (A) at the flywheel end as shown.2. Remove bridge (1) and the seals. 3. Remove rear main bearing cap (2). Be sure the location is marked on the main bearing cap before it is removed. The stamped location number is toward the camshaft. 4. Remove upper bearing half (3) with an approved bearing removal tool.

Do not turn the crankshaft in a counterclockwise direction because the tab of the bearing can be pushed between the crankshaft and the engine block. This will cause damage to the crankshaft and engine block.

5. Turn the crankshaft clockwise, as seen from the flywheel, to remove bearing upper half (3). 6. Remove bearing lower half (4) from rear main bearing cap (2). 7. Put the bearing upper half (3) in position on the crankshaft, and use the removal tool to rotate the bearing into position. Turn the crankshaft in a counterclockwise direction to engage bearing tab with the engine block. 8. Install the bearing lower half in the main bearing cap.9. Put a piece of Plastigage (5) across the crankshaft main bearing face. Install main bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.10. Put the main bearing cap in position. Put clean engine oil on the threads of the main bearing cap bolts, and tighten them finger tight.11. Tighten the main bearing

Start By:a. remove engine and transmissionb. remove oil pumpc. remove crankshaft rear seal 1. Fasten the engine to tool (A) at the flywheel end as shown.2. Remove bridge (1) and the seals. 3. Remove rear main bearing cap (2). Be sure the location is marked on the main bearing cap before it is removed. The stamped location number is toward the camshaft. 4. Remove upper bearing half (3) with an approved bearing removal tool.

Do not turn the crankshaft in a counterclockwise direction because the tab of the bearing can be pushed between the crankshaft and the engine block. This will cause damage to the crankshaft and engine block.

5. Turn the crankshaft clockwise, as seen from the flywheel, to remove bearing upper half (3). 6. Remove bearing lower half (4) from rear main bearing cap (2). 7. Put the bearing upper half (3) in position on the crankshaft, and use the removal tool to rotate the bearing into position. Turn the crankshaft in a counterclockwise direction to engage bearing tab with the engine block. 8. Install the bearing lower half in the main bearing cap.9. Put a piece of Plastigage (5) across the crankshaft main bearing face. Install main bearings dry when the clearance checks are made. Put clean engine oil on the main bearings for final assembly.10. Put the main bearing cap in position. Put clean engine oil on the threads of the main bearing cap bolts, and tighten them finger tight.11. Tighten the main bearing