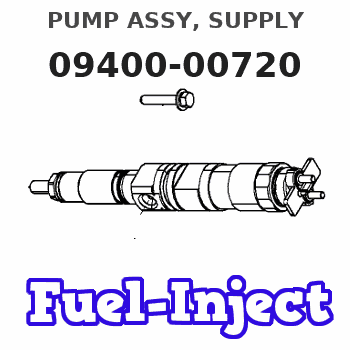

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Oil Pump Model: 094000-0720 094000-0722 8-97625496-0 8-97625496-3

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

HP0 Diesel Injection Fuel Pump 094000-0720 094000-0722 8-97625496-0 8-97625496-3

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

WSVKJLGR Tip: Before placing your order, please carefully check and confirm that the model and part number of the fuel injection pump you order matches the specifications of your specific equipment. || Simple installation: reasonable design and simple installation steps to ensure the normal function of the fuel injection pump. || Precise control: Precise control of fuel flow makes engine power output more stable. || Stable pressure: stable output of fuel pressure under various working conditions to ensure continuous and stable operation of the engine. || High-precision injection: The injection pump adopts advanced technology to achieve high-precision fuel injection to ensure full fuel combustion and improve engine performance.

094000-0722 094000-0721 094000-0720 8-97625496-3 8-97625496-2 HP0 Fuel Injection Pump for Isuzu Giga 6UZ1 6TE1 Diesel Engine

HIRINTOL 🔸Replace Part Number: 094000-0722, 094000-0721, 094000-0720, 8-97625496-4, 8-97625496-3, , 8-97625496-2, 8-97625496-1, 8-97625496-0 || 🔸Compatible Model: for Isuzu Giga 6UZ1 6TE1 Diesel Engine || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

HIRINTOL 🔸Replace Part Number: 094000-0722, 094000-0721, 094000-0720, 8-97625496-4, 8-97625496-3, , 8-97625496-2, 8-97625496-1, 8-97625496-0 || 🔸Compatible Model: for Isuzu Giga 6UZ1 6TE1 Diesel Engine || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

Components :

| 001. | PUMP ASSY, SUPPLY | 09400-00720 |

| 002. | OVERHAUL KIT, SUPP | 09404-00010 |

| 003. | BODY ASSY, SUPPLY | 09410-00582 |

| 004. | PUMP ASSY, FUEL FE | 09420-00460 |

Scheme ###:

| 000. | [01] | 09400-00722 | PUMP ASSY, SUPPLY | 8-97625496-3 |

| 000-001. | [01] | 09404-00010 | OVERHAUL KIT, SUPP | |

| 003. | [01] | 09410-00582 | BODY ASSY, SUPPLY | |

| 004. | [01] | 09420-00460 | PUMP ASSY, FUEL FE | |

| 005. | [01] | 94904-43320 | BOLT | |

| 006. | [04] | 09644-90070 | BOLT, SOCKET | 8-97141258-0 |

| 011. | [01] | 09255-11030 | BLOCK, COUPLING | |

| 012. | [01] | 09001-20310 | NUT, TIMER ROUND | |

| 013. | [01] | 90458-05750 | KEY, WOODRUFF |

Cross reference number

| Part num | Firm num | Firm | Name |

| 09400-00720 | PUMP ASSY, SUPPLY | ||

| 8-97625496-3 | ISUZU | PUMP ASSY, SUPPLY |

Information:

Part of the 8S2245 Cleaning Group.Start By:a. remove valve covers 1. Use tooling (A), and disconnect fuel line (1) at each end. Remove the fuel line from the engine. 2. Use tool (B), and remove retainer (2) from the adapter.3. Remove the fuel injection nozzles with tooling (C) as follows:a. Install the 6V6983 Adapter and the 8T3199 Screw into nozzle assembly (3).b. Install the 8T3198 Tube over the 8T3199 Screw.c. Use the 1B4206 Nut on the 8T3199 Screw.d. Use the 1B4206 Nut on the 8T3199 Screw to pull the fuel injection nozzle from the adapter.4. Remove compression seal (4) and carbon dam seal (8) from fuel injection nozzle (3).5. Use tool (D), and remove adapter (6) from the cylinder head.6. Remove gasket (7) and seal (5) from adapter (6). The following steps are for installation of the fuel injection nozzles and adapters.7. Use tool (E) to clean the bore in adapter (6). Use an open end wrench or tap driver to turn tool (E).8. Inspect seal (5) for damage or wear. Replace the seal if necessary.9. Put washer (7) and seal (5) in position on adapter (6).10. Put liquid soap in the bores of the cylinder head and on seals (5) in the adapters.11. Put 5P3931 Anti-Seize Compound on the threads of adapter (6), and install the adapter in the cylinder head assembly.12. Use tool (D), and tighten the adapter to a torque of 205 14 N m (150 10 lb.ft.).

Make sure the correct compression seal washer (4) is used when the nozzle assembly is installed in the adapter. Only copper washers are to be used with this adapter.

13. Install compression seal washer (4), and use tool (F) to install carbon dam seal (8) on the fuel injection nozzle.14. Put fuel injection nozzle (3) in position in the adapter, and install retainer (2).15. Use tool (B) to tighten retainer (2) to a torque of 48 7 N m (35 5 lb.ft.).16. Install fuel line (1). Tighten the nuts on the fuel line with tooling (A) to a torque of 40 7 N m (30 5 lb.ft.).End By:a. install valve covers

Make sure the correct compression seal washer (4) is used when the nozzle assembly is installed in the adapter. Only copper washers are to be used with this adapter.

13. Install compression seal washer (4), and use tool (F) to install carbon dam seal (8) on the fuel injection nozzle.14. Put fuel injection nozzle (3) in position in the adapter, and install retainer (2).15. Use tool (B) to tighten retainer (2) to a torque of 48 7 N m (35 5 lb.ft.).16. Install fuel line (1). Tighten the nuts on the fuel line with tooling (A) to a torque of 40 7 N m (30 5 lb.ft.).End By:a. install valve covers