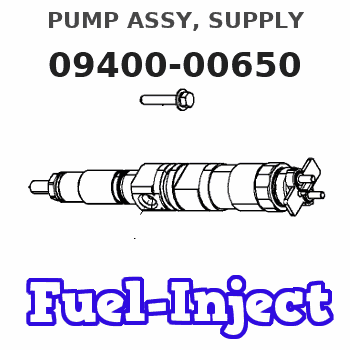

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 094000-0830 D28C001800 Compatible with SDEC Truck

Starhycfa Product name:Fuel Injection Pump || Part Number:094000-0830 D28C001800 || APPlication:Compatible with SDEC Truck || 1.Please carefully compare the pictures or OE numbers to match your original parts beCompatible withe purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours beCompatible withe order. To Avoid placing wrong orders and wasting your precious time.

Starhycfa Product name:Fuel Injection Pump || Part Number:094000-0830 D28C001800 || APPlication:Compatible with SDEC Truck || 1.Please carefully compare the pictures or OE numbers to match your original parts beCompatible withe purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours beCompatible withe order. To Avoid placing wrong orders and wasting your precious time.

Aftermarket Fuel Injection Pump 094000-0550 094000-0650 Fit Intended For Engine SC9DK Truck

Generic Motorcycle Parts || Heavy Equipment Parts || Spare Parts || Fuel Systems

Generic Motorcycle Parts || Heavy Equipment Parts || Spare Parts || Fuel Systems

094000-0652 094000-0651 D28C-001-800 Fuel Injection Pump for SDEC STEC Engine SC8DK SC9DK Truck

HIRINTOL 🔸Replace Part Number: 094000-0652, 094000-0651, 094000-0650, D28C-001-800 || 🔸Compatible Model: For SDEC STEC Engine SC8DK SC9DK Truck || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

HIRINTOL 🔸Replace Part Number: 094000-0652, 094000-0651, 094000-0650, D28C-001-800 || 🔸Compatible Model: For SDEC STEC Engine SC8DK SC9DK Truck || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

You can express buy:

Components :

| 001. | PUMP ASSY, SUPPLY | 09400-00650 |

| 001. | PUMP ASSY, SUPPLY | 09400-00650 |

| 002. | BODY ASSY, SUPPLY | 09410-00540 |

| 003. | PUMP ASSY, FUEL FE | 09420-00370 |

| 003. | PUMP ASSY, FUEL FE | 09420-00370 |

| 003. | PUMP ASSY, FUEL FE | 09420-00370 |

| 003. | PUMP ASSY, FUEL FE | 09420-00370 |

| 003. | PUMP ASSY, FUEL FE | 09420-00370 |

Scheme ###:

| 000. | [01] | 09400-00650 | PUMP ASSY, SUPPLY | D28C001800 |

| 000. | [01] | 09400-00650 | PUMP ASSY, SUPPLY | D28C001800A |

| 000-001. | [01] | 09404-00030 | OVERHAUL KIT, SUPP | |

| 001. | [01] | 09408-60210 | O-RING, SUPPLY PUM | |

| 002. | [09] | 09022-20070 | WASHER, FUEL PIPE | |

| 003. | [02] | 09022-20120 | WASHER, FUEL PIPE | |

| 003. | [01] | 09410-00540 | BODY ASSY, SUPPLY | |

| 004. | [01] | 94905-63990 | NUT | |

| 004. | [01] | 09420-00370 | PUMP ASSY, FUEL FE | |

| 005. | [01] | 09002-10040 | KEY, WOODRUFF | |

| 005. | [01] | 94904-43320 | BOLT | |

| 006. | [04] | 09644-90070 | BOLT, SOCKET | |

| 007. | [01] | 09408-60210 | O-RING, SUPPLY PUM |

Include in #3:

09400-00650

as PUMP ASSY, SUPPLY

09400-00650

Cross reference number

| Part num | Firm num | Firm | Name |

| 09400-00650 | D28C001800 | PUMP ASSY, SUPPLY | |

| 028C-001-800A | SDEC | PUMP ASSY SUPPLY | |

| D28C001800 | OTHERS | PUMP ASSY, SUPPLY | |

| D28C001800A | SDEC | PUMP ASSY, SUPPLY |

Information:

Start By:a. remove fuel injection lines 1. Remove bolt (1) and clamp (2) from the fuel injection nozzles to be removed.2. Install Tool (A) with the inside lip of the puller on the lower stepped diameter of the nozzle and the tip of the button in the threaded hole for bolt (1).

Do not exceed a torque of 17 N m (150 lb in) on the screw of Tool (A) during removal of the nozzle. Added force can cause the stem of the nozzle to bend or break off.

3. Tighten the screw of Tool (A) to a maximum torque of 17 N m (150 lb in) to remove fuel injection nozzle (3).4. If the fuel injection nozzle can not be removed with a maximum torque of 17 N m (150 lb in) on the screw of Tool (A), remove Tool (A).

Typical Example5. Remove the protective cap from fuel injection nozzle (3), and install Tool (B) as shown.

Hold Tool (B) so the center line of the tool is in alignment with the centerline of fuel injection nozzle (3). This will prevent distortion of the nozzle which can cause it to bend or break off during removal.

6. Remove the fuel injection nozzle with Tool (B).7. If Tool (B) was used to remove the fuel injection nozzle, replace the nozzle.8. If Tool (A) was used to remove the fuel injection nozzle, remove the carbon dam seal on the end of the nozzle.Install Fuel Injection Nozzle

1. Use Tool (C) to clean the bore for the fuel injection nozzle. Use an open end wrench or tap driver to turn Tool (C).2. Make reference to Special Instruction, Form No. SEHS7292, for the use of Tool (D). Clean the fuel injection nozzle with Tool (D). 3. Install a new seal (4) on fuel injection nozzle (3).4. Put carbon dam seal (5) on the small end of Tool (E). Expand the carbon dam seal by sliding it to the large end. Put Tool (E) against the fuel injection nozzle. Slide carbon dam seal (5) off Tool (E) on to the nozzle. Slide the carbon dam seal into position in the groove on the nozzle as shown. 5. Put fuel injection nozzle (3) in position in the cylinder head. Install clamp (2) and bolt (1) to hold the nozzle in position.End By:a. install fuel injection lines

Do not exceed a torque of 17 N m (150 lb in) on the screw of Tool (A) during removal of the nozzle. Added force can cause the stem of the nozzle to bend or break off.

3. Tighten the screw of Tool (A) to a maximum torque of 17 N m (150 lb in) to remove fuel injection nozzle (3).4. If the fuel injection nozzle can not be removed with a maximum torque of 17 N m (150 lb in) on the screw of Tool (A), remove Tool (A).

Typical Example5. Remove the protective cap from fuel injection nozzle (3), and install Tool (B) as shown.

Hold Tool (B) so the center line of the tool is in alignment with the centerline of fuel injection nozzle (3). This will prevent distortion of the nozzle which can cause it to bend or break off during removal.

6. Remove the fuel injection nozzle with Tool (B).7. If Tool (B) was used to remove the fuel injection nozzle, replace the nozzle.8. If Tool (A) was used to remove the fuel injection nozzle, remove the carbon dam seal on the end of the nozzle.Install Fuel Injection Nozzle

1. Use Tool (C) to clean the bore for the fuel injection nozzle. Use an open end wrench or tap driver to turn Tool (C).2. Make reference to Special Instruction, Form No. SEHS7292, for the use of Tool (D). Clean the fuel injection nozzle with Tool (D). 3. Install a new seal (4) on fuel injection nozzle (3).4. Put carbon dam seal (5) on the small end of Tool (E). Expand the carbon dam seal by sliding it to the large end. Put Tool (E) against the fuel injection nozzle. Slide carbon dam seal (5) off Tool (E) on to the nozzle. Slide the carbon dam seal into position in the groove on the nozzle as shown. 5. Put fuel injection nozzle (3) in position in the cylinder head. Install clamp (2) and bolt (1) to hold the nozzle in position.End By:a. install fuel injection lines