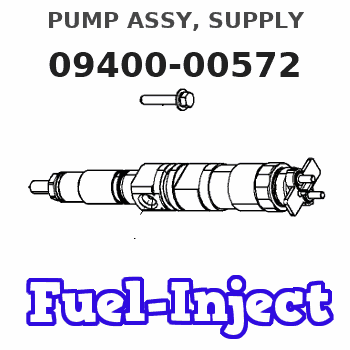

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

IMELBUFF 094000-0570 094000-0571 094000-0572 094000-0574 6251-71-1121 CR HP0 Fuel Injection Pump for Komatsu SAA6D125E Engine PC400-8 PC400LC-8 PC450-8 PC450-8R Excavator

IMELBUFF 🚜Part Number: 094000-0570 094000-0571 094000-0572 094000-0573 094000-0574 6251-71-1120 6251-71-1121 || 🚜Engine Model: for Komatsu Engine SA6D125 || 🚜Application: for Komatsu Excavator PC400-8 PC400LC-8 PC450-8 PC450-8R; for Komatsu WA320 WA470 Wheel Loader || 🚜Warm Tips: If you are not sure that the pump is suitable for your vehicle, please send us email with your vehicle engine model and fuel pump part number || 🚜Service: 6-months-warranty and 24 hour support for customer service. Please feel free to contact us by email if you have any question with the product

IMELBUFF 🚜Part Number: 094000-0570 094000-0571 094000-0572 094000-0573 094000-0574 6251-71-1120 6251-71-1121 || 🚜Engine Model: for Komatsu Engine SA6D125 || 🚜Application: for Komatsu Excavator PC400-8 PC400LC-8 PC450-8 PC450-8R; for Komatsu WA320 WA470 Wheel Loader || 🚜Warm Tips: If you are not sure that the pump is suitable for your vehicle, please send us email with your vehicle engine model and fuel pump part number || 🚜Service: 6-months-warranty and 24 hour support for customer service. Please feel free to contact us by email if you have any question with the product

CR HP0 Fuel Injection Pump for Komatsu SAA6D125E Engine PC400-8 PC400LC-8 PC450-8 PC450-8R Excavator 094000-0570 094000-0571 094000-0572 094000-0574 6251-71-1121

KoovDem Part Number: 094000-0570 094000-0571 094000-0572 094000-0573 094000-0574 6251-71-1120 6251-71-1121 || Application:For Komatsu Excavator PC400-8 PC400LC-8 PC450-8 PC450-8R; for Komatsu WA320 WA470 Wheel Loader || The Komatsu SA6D125 engine, designed for heavy-duty applications, is a powerful and reliable choice for construction, mining, and other industrial settings. With advanced technology and high-quality components, this engine delivers exceptional power and torque for tackling tough working conditions. Trust in its durability and optimal productivity for efficient performance on the job site. || We are dedicated to assisting you in finding the perfect pump for your vehicle. Choosing the right pump is crucial for peak performance and longevity. Regular upkeep can prevent breakdowns and extend its lifespan. Follow manufacturer instructions for installation and usage. Contact us with any inquiries or for assistance. Thank you for choosing our products. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

KoovDem Part Number: 094000-0570 094000-0571 094000-0572 094000-0573 094000-0574 6251-71-1120 6251-71-1121 || Application:For Komatsu Excavator PC400-8 PC400LC-8 PC450-8 PC450-8R; for Komatsu WA320 WA470 Wheel Loader || The Komatsu SA6D125 engine, designed for heavy-duty applications, is a powerful and reliable choice for construction, mining, and other industrial settings. With advanced technology and high-quality components, this engine delivers exceptional power and torque for tackling tough working conditions. Trust in its durability and optimal productivity for efficient performance on the job site. || We are dedicated to assisting you in finding the perfect pump for your vehicle. Choosing the right pump is crucial for peak performance and longevity. Regular upkeep can prevent breakdowns and extend its lifespan. Follow manufacturer instructions for installation and usage. Contact us with any inquiries or for assistance. Thank you for choosing our products. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

CONERY Fuel Pump Spare Parts 6245-71-1101 for Fuel Injection Pump Pc1250-7 094000-0572

CONERY Fuel pump spare parts 6245-71-1101 for fuel injection pump pc1250-7 094000-0572 || Easy to install and can directly replace parts. || Made of high-quality materials, sturdy and durable. || Accelerate smoothly without stalling, ensuring stable pump oil performance at high temperatures. || The fuel pump module assembly helps to improve engine performance, ensure sufficient return oil flow, and ensure stable fuel pressure and sufficient cooling.

CONERY Fuel pump spare parts 6245-71-1101 for fuel injection pump pc1250-7 094000-0572 || Easy to install and can directly replace parts. || Made of high-quality materials, sturdy and durable. || Accelerate smoothly without stalling, ensuring stable pump oil performance at high temperatures. || The fuel pump module assembly helps to improve engine performance, ensure sufficient return oil flow, and ensure stable fuel pressure and sufficient cooling.

You can express buy:

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09400-00572 | 62517-1112 | PUMP ASSY, SUPPLY |

Information:

Remove Timing Gears

Start By:a. remove timing gear case cover1. Put the No. 1 piston at top dead center on the compression stroke. Be sure all the timing marks are in alignment with each other. 2. Remove plate (2) that holds idler gear (1). 3. Remove idler gear (1). 4. Inspect two bushings (3) in idler gear (1). See Engine Specifications for bushing diameter. Remove two bushings (3) if replacement is necessary. 5. Remove fuel injection pump drive gear (4). 6. Bend lock (5) away from the bolt. Remove the bolt and remove washer (6). 7. Remove camshaft drive gear (7) with tool (A).Install Timing Gears

1. Align the slot in gear (1) with the key in the camshaft. Put the camshaft gear in position on the camshaft. 2. Install washer (2), lock (3) and the bolt. Tighten the bolt to a torque of 60-70 N m (45-52 lb ft). Bend the tab of the lock against the bolt head. 3. Align the roll pin in fuel injection pump drive gear (4) with the hole in fuel injection pump drive shaft (5). Install fuel injection pump drive gear (4) on to fuel injection pump drive shaft (5). 4. Install three bolts (6) to hold drive gear (4) to the fuel injection pump drive shaft. 5. Use tool (A) to install two bushings (7) into idler gear (8). Install the bushings even with the outside of idler gear (8). 6. Align the timing marks on idler gear (8) with the crankshaft gear, camshaft drive gear and the fuel injection pump drive gear. 7. Install plate (9) and the bolts to hold idler gear (8) on the idler gear shaft. Tighten the three bolts to a torque of 40 N m (30 lb ft). 8. Check the idler gear end clearance. The clearance must be at least 0.25 mm (.010 in). 9. Fasten a steel plate to the timing gear case. Fasten tooling (A) to the plate as shown. Check the timing gear backlash. The backlash must be 0.08 - 0.15 mm (.003 - .006 in).

Start By:a. remove timing gear case cover1. Put the No. 1 piston at top dead center on the compression stroke. Be sure all the timing marks are in alignment with each other. 2. Remove plate (2) that holds idler gear (1). 3. Remove idler gear (1). 4. Inspect two bushings (3) in idler gear (1). See Engine Specifications for bushing diameter. Remove two bushings (3) if replacement is necessary. 5. Remove fuel injection pump drive gear (4). 6. Bend lock (5) away from the bolt. Remove the bolt and remove washer (6). 7. Remove camshaft drive gear (7) with tool (A).Install Timing Gears

1. Align the slot in gear (1) with the key in the camshaft. Put the camshaft gear in position on the camshaft. 2. Install washer (2), lock (3) and the bolt. Tighten the bolt to a torque of 60-70 N m (45-52 lb ft). Bend the tab of the lock against the bolt head. 3. Align the roll pin in fuel injection pump drive gear (4) with the hole in fuel injection pump drive shaft (5). Install fuel injection pump drive gear (4) on to fuel injection pump drive shaft (5). 4. Install three bolts (6) to hold drive gear (4) to the fuel injection pump drive shaft. 5. Use tool (A) to install two bushings (7) into idler gear (8). Install the bushings even with the outside of idler gear (8). 6. Align the timing marks on idler gear (8) with the crankshaft gear, camshaft drive gear and the fuel injection pump drive gear. 7. Install plate (9) and the bolts to hold idler gear (8) on the idler gear shaft. Tighten the three bolts to a torque of 40 N m (30 lb ft). 8. Check the idler gear end clearance. The clearance must be at least 0.25 mm (.010 in). 9. Fasten a steel plate to the timing gear case. Fasten tooling (A) to the plate as shown. Check the timing gear backlash. The backlash must be 0.08 - 0.15 mm (.003 - .006 in).