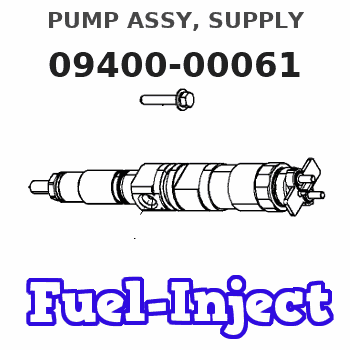

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Fuel Pump 094000-0390 22730-1120 094000-0061 22730-1022 Compatible for HINO 700 K13C Engine

Gvgsgtyu 094000-0390 22730-1120 094000-0061 22730-1022 700 K13C 700 K13C || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

Gvgsgtyu 094000-0390 22730-1120 094000-0061 22730-1022 700 K13C 700 K13C || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

Fuel Injection Pump 094000-0061 22730-1022 for Hino Engine K13C

ADPelcote Part number:094000-0061 || Applications:for Hino Engine K13C

ADPelcote Part number:094000-0061 || Applications:for Hino Engine K13C

Fuel Injection Pump 094000-0061 Truck Engine Fuel Injector Pump Compatible For 22730-1022 K13C Diesel Engine Replacement 094000-0061

WEIGONG Made of durable plastic and metal, this fuel pump assembly ensures the service life and reliability || The electric fuel pump has excellent design and stable operation, which reduces the risk of mechanical failure and improves the overall reliability || The simple structure of electric fuel pump makes maintenance more convenient and reduces the maintenance cost of long-term operation || Each fuel pump assembly undergoes rigorous testing to guarantee quality before || Fuel Injection Pump 094000-0061 Truck Engine Fuel Injector Pump Compatible For 22730-1022 K13C Diesel Engine Replacement 094000-0061

WEIGONG Made of durable plastic and metal, this fuel pump assembly ensures the service life and reliability || The electric fuel pump has excellent design and stable operation, which reduces the risk of mechanical failure and improves the overall reliability || The simple structure of electric fuel pump makes maintenance more convenient and reduces the maintenance cost of long-term operation || Each fuel pump assembly undergoes rigorous testing to guarantee quality before || Fuel Injection Pump 094000-0061 Truck Engine Fuel Injector Pump Compatible For 22730-1022 K13C Diesel Engine Replacement 094000-0061

You can express buy:

USD 817.46

13-05-2025

13-05-2025

094000-0061 Fuel Injection Pump Remanufactured 094000-0061 Truck Engine Fuel Injector Pump for 22730-1022 K13C Diesel Engine

Components :

| 001. | PUMP ASSY, SUPPLY | 09400-00061 |

| 002. | COUPLING ASSY | 09250-01112 |

| 003. | OVERHAUL KIT, SUPP | 09404-00010 |

| 004. | BODY ASSY, SUPPLY | 09410-00041 |

| 005. | PUMP ASSY, FUEL FE | 09420-00040 |

Scheme ###:

| 000. | [01] | 09400-00061 | PUMP ASSY, SUPPLY | 22730-1022 |

| 000-001. | [01] | 09404-00010 | OVERHAUL KIT, SUPP | |

| 003. | [01] | 09410-00041 | BODY ASSY, SUPPLY | |

| 004. | [01] | 09420-00040 | PUMP ASSY, FUEL FE | |

| 005. | [01] | 94904-43320 | BOLT | 22815-2070A |

| 006. | [04] | 09644-90070 | BOLT, SOCKET | |

| 007. | [01] | 09250-01112 | COUPLING ASSY | |

| 008. | [01] | 90458-05750 | KEY, WOODRUFF | 22891-1070A |

| 009. | [01] | 09001-20310 | NUT, TIMER ROUND | |

| 010. | [01] | 09069-00941 | BRACKET SUB-ASSY, | |

| 011. | [03] | 90128-08201 | BOLT, HEXAGON | 6 056 1607 60 |

| 012. | [03] | 90200-08081 | WASHER, PLATE | 9461C-10800 |

| 013. | [01] | 09255-10801 | BLOCK, COUPLING |

Include in #3:

09400-00061

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 09400-00061 | 22730-1022 | PUMP ASSY, SUPPLY |

Information:

D11N (74Z) Track-Type TractorIntroduction

This Special Instruction outlines the procedure for the installation of a 3508 Engine with electronic unit injection (EUI) into a D11N Tractor (74Z). The original engine in this machine was a 3508 Engine with mechanical unit injection (MUI). This Special Instruction does not cover conversion of the basic engine from MUI to EUI.The information covers a typical 3508 EUI Engine installation. It does not cover all situations one is likely to encounter, as a number of changes have been made to the machine since its introduction. Modifications and changes made by users and special attachments may also affect engine installation.During this engine installation a number of changes will be made to the tractor electrical system. Console mounted indicator lamps will be added to alert the operator to the need for air-cleaner servicing. Another lamp will signal that diagnostic information is present in the electronic control module (ECM) located on the engine. An engine overspeed indicator lamp will also be added to the console. The engine overspeed indicator is operated as part of the ECM. No changes will be made to the electronic monitoring system (EMS) which is part of the instrument panel. The dual cylinder ether starting aid system will be replaced by a single cylinder system.If a new or remanufactured EUI engine is being installed, the alternator will be located at the rear of the engine. The location of the refrigerant compressor, for the optional air conditioning system, has not been changed.Use care when installing the new components. Take note of the installation locations specified. Use care when making electrical connections between the new and existing components and systems.Reference Literature Parts Needed

Engine Removal

Disconnect the cables to the batteries to prevent the possibility of personal injury and/or damage to electrical or electronic equipment. Refer to Service Manual

This Special Instruction outlines the procedure for the installation of a 3508 Engine with electronic unit injection (EUI) into a D11N Tractor (74Z). The original engine in this machine was a 3508 Engine with mechanical unit injection (MUI). This Special Instruction does not cover conversion of the basic engine from MUI to EUI.The information covers a typical 3508 EUI Engine installation. It does not cover all situations one is likely to encounter, as a number of changes have been made to the machine since its introduction. Modifications and changes made by users and special attachments may also affect engine installation.During this engine installation a number of changes will be made to the tractor electrical system. Console mounted indicator lamps will be added to alert the operator to the need for air-cleaner servicing. Another lamp will signal that diagnostic information is present in the electronic control module (ECM) located on the engine. An engine overspeed indicator lamp will also be added to the console. The engine overspeed indicator is operated as part of the ECM. No changes will be made to the electronic monitoring system (EMS) which is part of the instrument panel. The dual cylinder ether starting aid system will be replaced by a single cylinder system.If a new or remanufactured EUI engine is being installed, the alternator will be located at the rear of the engine. The location of the refrigerant compressor, for the optional air conditioning system, has not been changed.Use care when installing the new components. Take note of the installation locations specified. Use care when making electrical connections between the new and existing components and systems.Reference Literature Parts Needed

Engine Removal

Disconnect the cables to the batteries to prevent the possibility of personal injury and/or damage to electrical or electronic equipment. Refer to Service Manual