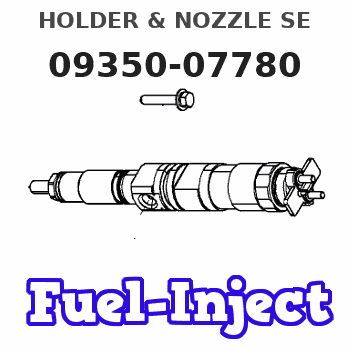

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-07780 |

Scheme ###:

| 000. | [01] | 09350-07780 | HOLDER & NOZZLE SE | 32C6107000 |

| 001. | [01] | 09310-07780 | HOLDER ASSY, NOZZL | 32C6107010 |

| 001-001. | [01] | 09311-07780 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10380 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70360 | SPRING, NOZZLE HOL | 47X0110100 |

| 001-004. | [01] | 09316-40951 | NUT, NOZZLE RETAIN | |

| 001-005. | [01] | 09317-40070 | DISTANCE PIECE | |

| 001-006. | [1C] | 09317-51980 | WASHER | |

| 001-006. | [1C] | 09317-51970 | WASHER | |

| 001-006. | [1C] | 09317-51960 | WASHER | |

| 001-006. | [1C] | 09317-51950 | WASHER | |

| 001-006. | [1C] | 09317-51940 | WASHER | |

| 001-006. | [1C] | 09317-51930 | WASHER | |

| 001-006. | [1C] | 09317-51920 | WASHER | |

| 001-006. | [1C] | 09317-51910 | WASHER | |

| 001-006. | [1C] | 09317-51900 | WASHER | |

| 001-006. | [1C] | 09317-51990 | WASHER | |

| 001-006. | [1C] | 09317-52000 | WASHER | |

| 001-006. | [1C] | 09317-52090 | WASHER | |

| 001-006. | [1C] | 09317-52080 | WASHER | |

| 001-006. | [1C] | 09317-52070 | WASHER | |

| 001-006. | [1C] | 09317-52060 | WASHER | |

| 001-006. | [1C] | 09317-52050 | WASHER | |

| 001-006. | [1C] | 09317-52040 | WASHER | |

| 001-006. | [1C] | 09317-52030 | WASHER | |

| 001-006. | [1C] | 09317-52020 | WASHER | |

| 001-006. | [1C] | 09317-52010 | WASHER | |

| 001-006. | [1C] | 09317-51890 | WASHER | |

| 001-006. | [1C] | 09317-51880 | WASHER | |

| 001-006. | [1C] | 09317-51870 | WASHER | |

| 001-006. | [1C] | 09317-51750 | WASHER | |

| 001-006. | [1C] | 09317-51740 | WASHER | |

| 001-006. | [1C] | 09317-51730 | WASHER | |

| 001-006. | [1C] | 09317-51720 | WASHER | |

| 001-006. | [1C] | 09317-51710 | WASHER | |

| 001-006. | [1C] | 09317-51700 | WASHER | |

| 001-006. | [1C] | 09317-51690 | WASHER | |

| 001-006. | [1C] | 09317-51680 | WASHER | |

| 001-006. | [1C] | 09317-51670 | WASHER | |

| 001-006. | [1C] | 09317-51760 | WASHER | |

| 001-006. | [1C] | 09317-51770 | WASHER | |

| 001-006. | [1C] | 09317-51860 | WASHER | |

| 001-006. | [1C] | 09317-51850 | WASHER | |

| 001-006. | [1C] | 09317-51840 | WASHER | |

| 001-006. | [1C] | 09317-51830 | WASHER | |

| 001-006. | [1C] | 09317-51820 | WASHER | |

| 001-006. | [1C] | 09317-51810 | WASHER | |

| 001-006. | [1C] | 09317-51800 | WASHER | |

| 001-006. | [1C] | 09317-51790 | WASHER | |

| 001-006. | [1C] | 09317-51780 | WASHER | |

| 002. | [01] | 09340-05210 | NOZZLE ASSY | 34661-02000 |

Include in #3:

09350-07780

as HOLDER & NOZZLE SE

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-07780 | 32C6107000 | HOLDER & NOZZLE SE | |

| 32C6107000 | MITSUBISHI | HOLDER & NOZZLE SE |

Information:

Specifications

Components parts

Fuel System Component Parts(1) Injection pump(2) Adjustment shim(3) Injection pipe(4) Injection nozzle(5) Return pipe(6) Fuel filter(7) Fuel cutoff solenoidFUEL INJECTION PUMP

Construction

Injection Pump Component Parts(1) Union collar(2) Air vent screw(3) Delivery valve holder(4) Valve spring(5) Holder stopper(6) Housing(7) O-ring(8) Delivery valve(9) Gasket(10) Seat valve(11) Plunger barrel(12) Sleeve(13) Upper seat(14) Plunger spring(15) Plunger(16) Lower seat(17) Adjusting shim(18) Tappet roller(19) Pin(20) Control rack(21) Stop wire bracketInspecting the injection pump while it is mounted on the engine

Never attempt to disassemble the pump unless it is necessary.If the pump is assumed defective, it is recommended to replace the pump assembly. Removal

(1) Disconnect the fuel injection pipes.(2) Remove the tie-rod clip cover.(3) Remove the tie-rod clip and tie-rod.(4) Remove the injection pump assembly.

Removing Injection PumpDisassembly

(1) Remove the stopper plate.(2) Unscrew the delivery holder. Take out the delivery valve and valve spring.(3) Remove the tappet roller and stopper pin.(4) Remove the tappet, plunger spring, etc. CAUTION1. When replacing the plunger barrel, delivery valve, etc., do not loosen the adjusting screw and plate for each cylinder.2. When those parts have been replaced, it is necessary to measure fuel injection quantity by using the pump tester and cam box.3. All parts removed from the pump should be kept classified by cylinders and immersed in clean fuel.Inspection

Inspection of Injection PumpAssembly

(1) Insert the plunger barrel into the housing.(2) Install the delivery valve and valve spring. Temporarily tighten the holder.(3) Insert the control rack.(4) Insert the control pinion. Align the matchmark on the rack with that on the pinion.(5) Install the spring upper seat.(6) Insert the plunger spring.(7) Fit the lower seat to the plunger. Insert the plunger into the barrel side.(8) Depress the tappet roller assembly and install the stopper pin.(9) Tighten the delivery holder. Tightening torque : 3.5 - 3.9 kgm

Direction of Installation of PlungerInstallation

Install the injection pump assembly in the reverse order of removal. CAUTION* When installing the plunger barrel, engage the dowel pin on the housing side with the groove in the barrel.* Position the plunger so that the part-number stamp on its flanges faces the direction opposite to the rack side. (Engage the feed hole with the plunger lead.)* After installation, check for proper injection timing.INJECTION NOZZLE

Construction

Nozzle Holder Ass'y Component Parts(1) Body sub-assembly(2) Shim washer(3) Pressure spring(4) Pin(5) Distance piece(6) Nozzle assembly(7) Retaining nutRemoval

(1) Disconnect the injection pipe and fuel return pipe.(2) Remove the injection nozzle assembly from the cylinder head. CAUTION* Attach an identification-number tag to the removed injection nozzle.* Plug the openings, from which the pipes are disconnected and the nozzle is removed, to prevent intrusion of dust, water, and other foreign particles into the pipes and combustion chamber.Disassembly

If the removed nozzle assembly is assumed defective, disassemble the assembly and repair or replace the faulty parts.(1) Grip the nozzle holder body in a vise. Loosen the retaining nut. Never vise the retaining nut to prevent deformation.(2) Take out the shim washer, pressure spring, distance piece, and nozzle assembly. CAUTION* Scrape off carbon deposit with a wooden spatula. Keep the removed parts immersed

Components parts

Fuel System Component Parts(1) Injection pump(2) Adjustment shim(3) Injection pipe(4) Injection nozzle(5) Return pipe(6) Fuel filter(7) Fuel cutoff solenoidFUEL INJECTION PUMP

Construction

Injection Pump Component Parts(1) Union collar(2) Air vent screw(3) Delivery valve holder(4) Valve spring(5) Holder stopper(6) Housing(7) O-ring(8) Delivery valve(9) Gasket(10) Seat valve(11) Plunger barrel(12) Sleeve(13) Upper seat(14) Plunger spring(15) Plunger(16) Lower seat(17) Adjusting shim(18) Tappet roller(19) Pin(20) Control rack(21) Stop wire bracketInspecting the injection pump while it is mounted on the engine

Never attempt to disassemble the pump unless it is necessary.If the pump is assumed defective, it is recommended to replace the pump assembly. Removal

(1) Disconnect the fuel injection pipes.(2) Remove the tie-rod clip cover.(3) Remove the tie-rod clip and tie-rod.(4) Remove the injection pump assembly.

Removing Injection PumpDisassembly

(1) Remove the stopper plate.(2) Unscrew the delivery holder. Take out the delivery valve and valve spring.(3) Remove the tappet roller and stopper pin.(4) Remove the tappet, plunger spring, etc. CAUTION1. When replacing the plunger barrel, delivery valve, etc., do not loosen the adjusting screw and plate for each cylinder.2. When those parts have been replaced, it is necessary to measure fuel injection quantity by using the pump tester and cam box.3. All parts removed from the pump should be kept classified by cylinders and immersed in clean fuel.Inspection

Inspection of Injection PumpAssembly

(1) Insert the plunger barrel into the housing.(2) Install the delivery valve and valve spring. Temporarily tighten the holder.(3) Insert the control rack.(4) Insert the control pinion. Align the matchmark on the rack with that on the pinion.(5) Install the spring upper seat.(6) Insert the plunger spring.(7) Fit the lower seat to the plunger. Insert the plunger into the barrel side.(8) Depress the tappet roller assembly and install the stopper pin.(9) Tighten the delivery holder. Tightening torque : 3.5 - 3.9 kgm

Direction of Installation of PlungerInstallation

Install the injection pump assembly in the reverse order of removal. CAUTION* When installing the plunger barrel, engage the dowel pin on the housing side with the groove in the barrel.* Position the plunger so that the part-number stamp on its flanges faces the direction opposite to the rack side. (Engage the feed hole with the plunger lead.)* After installation, check for proper injection timing.INJECTION NOZZLE

Construction

Nozzle Holder Ass'y Component Parts(1) Body sub-assembly(2) Shim washer(3) Pressure spring(4) Pin(5) Distance piece(6) Nozzle assembly(7) Retaining nutRemoval

(1) Disconnect the injection pipe and fuel return pipe.(2) Remove the injection nozzle assembly from the cylinder head. CAUTION* Attach an identification-number tag to the removed injection nozzle.* Plug the openings, from which the pipes are disconnected and the nozzle is removed, to prevent intrusion of dust, water, and other foreign particles into the pipes and combustion chamber.Disassembly

If the removed nozzle assembly is assumed defective, disassemble the assembly and repair or replace the faulty parts.(1) Grip the nozzle holder body in a vise. Loosen the retaining nut. Never vise the retaining nut to prevent deformation.(2) Take out the shim washer, pressure spring, distance piece, and nozzle assembly. CAUTION* Scrape off carbon deposit with a wooden spatula. Keep the removed parts immersed