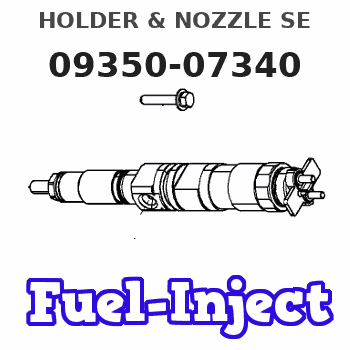

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-07340 |

| 001. | HOLDER & NOZZLE SE | 09350-07340 |

| 001. | HOLDER & NOZZLE SE | 09350-07340 |

Scheme ###:

| 000. | [01] | 09350-07340 | HOLDER & NOZZLE SE | R2S2 13 H50 |

| 000. | [01] | 09350-07340 | HOLDER & NOZZLE SE | |

| 000. | [01] | 09350-07340 | HOLDER & NOZZLE SE | MQ901765 |

| 001. | [01] | 09310-07340 | HOLDER ASSY, NOZZL | |

| 001. | [01] | 09310-07340 | HOLDER ASSY, NOZZL | |

| 001. | [01] | 09310-07340 | HOLDER ASSY, NOZZL | |

| 001-001. | [01] | 09311-07340 | BODY SUB-ASSY, NOZ | |

| 001-001. | [01] | 09311-07340 | BODY SUB-ASSY, NOZ | |

| 001-001. | [01] | 09311-07340 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10380 | PIN, NOZZLE HOLDER | ME736852 |

| 001-002. | [01] | 09312-10380 | PIN, NOZZLE HOLDER | RF66 13 TV4 |

| 001-002. | [01] | 09312-10380 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70450 | SPRING, NOZZLE HOL | |

| 001-003. | [01] | 09312-70450 | SPRING, NOZZLE HOL | |

| 001-003. | [01] | 09312-70450 | SPRING, NOZZLE HOL | ME736853 |

| 001-004. | [01] | 09316-40961 | NUT, NOZZLE RETAIN | |

| 001-004. | [01] | 09316-40961 | NUT, NOZZLE RETAIN | |

| 001-004. | [01] | 09316-41341 | NUT, NOZZLE RETAIN | |

| 001-004. | [01] | 09316-41341 | NUT, NOZZLE RETAIN | |

| 001-004. | [01] | 09316-40961 | NUT, NOZZLE RETAIN | |

| 001-004. | [01] | 09316-41341 | NUT, NOZZLE RETAIN | |

| 001-005. | [01] | 09317-40090 | DISTANCE PIECE | |

| 001-005. | [01] | 09317-40090 | DISTANCE PIECE | ME736854 |

| 001-005. | [01] | 09317-40090 | DISTANCE PIECE | |

| 001-006. | [1C] | 09317-51700 | WASHER | |

| 001-006. | [1C] | 09317-51690 | WASHER | |

| 001-006. | [1C] | 09317-51680 | WASHER | |

| 001-006. | [1C] | 09317-51850 | WASHER | |

| 001-006. | [1C] | 09317-51670 | WASHER | |

| 001-006. | [1C] | 09317-52020 | WASHER | ME736879 |

| 001-006. | [1C] | 09317-51930 | WASHER | MM501852 |

| 001-006. | [1C] | 09317-51940 | WASHER | ME736874 |

| 001-006. | [1C] | 09317-51950 | WASHER | MM501853 |

| 001-006. | [1C] | 09317-51960 | WASHER | ME736875 |

| 001-006. | [1C] | 09317-51970 | WASHER | MM501854 |

| 001-006. | [1C] | 09317-51980 | WASHER | ME736876 |

| 001-006. | [1C] | 09317-51990 | WASHER | MM501855 |

| 001-006. | [1C] | 09317-52000 | WASHER | ME736877 |

| 001-006. | [1C] | 09317-52010 | WASHER | ME736878 |

| 001-006. | [1C] | 09317-52030 | WASHER | ME736880 |

| 001-006. | [1C] | 09317-52040 | WASHER | ME736881 |

| 001-006. | [1C] | 09317-52050 | WASHER | ME736882 |

| 001-006. | [1C] | 09317-52060 | WASHER | ME736883 |

| 001-006. | [1C] | 09317-52070 | WASHER | ME736884 |

| 001-006. | [1C] | 09317-52080 | WASHER | ME736885 |

| 001-006. | [1C] | 09317-52090 | WASHER | ME736886 |

| 001-006. | [1C] | 09317-51920 | WASHER | ME736873 |

| 001-006. | [1C] | 09317-51710 | WASHER | |

| 001-006. | [1C] | 09317-51920 | WASHER | |

| 001-006. | [1C] | 09317-51930 | WASHER | |

| 001-006. | [1C] | 09317-51940 | WASHER | |

| 001-006. | [1C] | 09317-51950 | WASHER | |

| 001-006. | [1C] | 09317-51960 | WASHER | |

| 001-006. | [1C] | 09317-51970 | WASHER | |

| 001-006. | [1C] | 09317-51980 | WASHER | |

| 001-006. | [1C] | 09317-51990 | WASHER | |

| 001-006. | [1C] | 09317-52000 | WASHER | |

| 001-006. | [1C] | 09317-52010 | WASHER | |

| 001-006. | [1C] | 09317-52020 | WASHER | |

| 001-006. | [1C] | 09317-52030 | WASHER | |

| 001-006. | [1C] | 09317-52040 | WASHER | |

| 001-006. | [1C] | 09317-52050 | WASHER | |

| 001-006. | [1C] | 09317-52060 | WASHER | |

| 001-006. | [1C] | 09317-52070 | WASHER | |

| 001-006. | [1C] | 09317-52080 | WASHER | |

| 001-006. | [1C] | 09317-51910 | WASHER | |

| 001-006. | [1C] | 09317-51900 | WASHER | |

| 001-006. | [1C] | 09317-51720 | WASHER | |

| 001-006. | [1C] | 09317-51730 | WASHER | |

| 001-006. | [1C] | 09317-51740 | WASHER | |

| 001-006. | [1C] | 09317-51750 | WASHER | |

| 001-006. | [1C] | 09317-51760 | WASHER | |

| 001-006. | [1C] | 09317-51770 | WASHER | |

| 001-006. | [1C] | 09317-51780 | WASHER | |

| 001-006. | [1C] | 09317-51790 | WASHER | |

| 001-006. | [1C] | 09317-51800 | WASHER | |

| 001-006. | [1C] | 09317-51810 | WASHER | |

| 001-006. | [1C] | 09317-51820 | WASHER | |

| 001-006. | [1C] | 09317-51830 | WASHER | |

| 001-006. | [1C] | 09317-51840 | WASHER | |

| 001-006. | [1C] | 09317-51860 | WASHER | |

| 001-006. | [1C] | 09317-51870 | WASHER | |

| 001-006. | [1C] | 09317-51880 | WASHER | |

| 001-006. | [1C] | 09317-51890 | WASHER | |

| 001-006. | [1C] | 09317-52090 | WASHER | |

| 001-006. | [1C] | 09317-51910 | WASHER | MM501851 |

| 001-006. | [1C] | 09317-51670 | WASHER | |

| 001-006. | [1C] | 09317-51860 | WASHER | |

| 001-006. | [1C] | 09317-51870 | WASHER | RF66 13 TW9 |

| 001-006. | [1C] | 09317-51880 | WASHER | |

| 001-006. | [1C] | 09317-51890 | WASHER | RF66 13 TX1 |

| 001-006. | [1C] | 09317-51900 | WASHER | |

| 001-006. | [1C] | 09317-51910 | WASHER | RF66 13 TX2 |

| 001-006. | [1C] | 09317-51930 | WASHER | RF66 13 TX3 |

| 001-006. | [1C] | 09317-51940 | WASHER | |

| 001-006. | [1C] | 09317-51950 | WASHER | RF66 13 TX4 |

| 001-006. | [1C] | 09317-51960 | WASHER | |

| 001-006. | [1C] | 09317-51970 | WASHER | RF66 13 TX5 |

| 001-006. | [1C] | 09317-51980 | WASHER | |

| 001-006. | [1C] | 09317-51990 | WASHER | RF66 13 TX6 |

| 001-006. | [1C] | 09317-52000 | WASHER | |

| 001-006. | [1C] | 09317-52010 | WASHER | RF66 13 TX7 |

| 001-006. | [1C] | 09317-51850 | WASHER | RF66 13 TW8 |

| 001-006. | [1C] | 09317-51840 | WASHER | |

| 001-006. | [1C] | 09317-51830 | WASHER | RF66 13 TW7 |

| 001-006. | [1C] | 09317-51680 | WASHER | |

| 001-006. | [1C] | 09317-51690 | WASHER | |

| 001-006. | [1C] | 09317-51700 | WASHER | |

| 001-006. | [1C] | 09317-51710 | WASHER | RF66 13 TW1 |

| 001-006. | [1C] | 09317-51720 | WASHER | |

| 001-006. | [1C] | 09317-51730 | WASHER | RF66 13 TW2 |

| 001-006. | [1C] | 09317-51740 | WASHER | |

| 001-006. | [1C] | 09317-51750 | WASHER | RF66 13 TW3 |

| 001-006. | [1C] | 09317-51760 | WASHER | |

| 001-006. | [1C] | 09317-51770 | WASHER | RF66 13 TW4 |

| 001-006. | [1C] | 09317-51780 | WASHER | |

| 001-006. | [1C] | 09317-51790 | WASHER | RF66 13 TW5 |

| 001-006. | [1C] | 09317-51800 | WASHER | |

| 001-006. | [1C] | 09317-51810 | WASHER | RF66 13 TW6 |

| 001-006. | [1C] | 09317-51820 | WASHER | |

| 001-006. | [1C] | 09317-52020 | WASHER | |

| 001-006. | [1C] | 09317-52030 | WASHER | RF66 13 TX8 |

| 001-006. | [1C] | 09317-51750 | WASHER | ME736863 |

| 001-006. | [1C] | 09317-51760 | WASHER | ME736864 |

| 001-006. | [1C] | 09317-51770 | WASHER | ME736865 |

| 001-006. | [1C] | 09317-51780 | WASHER | ME736866 |

| 001-006. | [1C] | 09317-51790 | WASHER | MD603489 |

| 001-006. | [1C] | 09317-51800 | WASHER | ME736867 |

| 001-006. | [1C] | 09317-51810 | WASHER | MM501846 |

| 001-006. | [1C] | 09317-51820 | WASHER | ME736868 |

| 001-006. | [1C] | 09317-51830 | WASHER | MM501847 |

| 001-006. | [1C] | 09317-51840 | WASHER | ME736869 |

| 001-006. | [1C] | 09317-51850 | WASHER | MM501848 |

| 001-006. | [1C] | 09317-51860 | WASHER | ME736870 |

| 001-006. | [1C] | 09317-51870 | WASHER | MM501849 |

| 001-006. | [1C] | 09317-51880 | WASHER | ME736871 |

| 001-006. | [1C] | 09317-51890 | WASHER | MM501850 |

| 001-006. | [1C] | 09317-51900 | WASHER | ME736872 |

| 001-006. | [1C] | 09317-51740 | WASHER | ME736862 |

| 001-006. | [1C] | 09317-51730 | WASHER | ME736861 |

| 001-006. | [1C] | 09317-52050 | WASHER | RF66 13 TX9 |

| 001-006. | [1C] | 09317-52060 | WASHER | |

| 001-006. | [1C] | 09317-52070 | WASHER | RF66 13 TY1 |

| 001-006. | [1C] | 09317-52080 | WASHER | |

| 001-006. | [1C] | 09317-52090 | WASHER | RF66 13 TY2 |

| 001-006. | [1C] | 09317-51920 | WASHER | |

| 001-006. | [1C] | 09317-52040 | WASHER | |

| 001-006. | [1C] | 09317-51670 | WASHER | ME736855 |

| 001-006. | [1C] | 09317-51680 | WASHER | ME736856 |

| 001-006. | [1C] | 09317-51690 | WASHER | ME736857 |

| 001-006. | [1C] | 09317-51700 | WASHER | ME736858 |

| 001-006. | [1C] | 09317-51710 | WASHER | ME736859 |

| 001-006. | [1C] | 09317-51720 | WASHER | ME736860 |

| 001-008. | [01] | 94905-04260 | NUT, HEXAGON | |

| 001-008. | [01] | 94905-04260 | NUT, HEXAGON | |

| 001-008. | [01] | 94905-04260 | NUT, HEXAGON | |

| 002. | [01] | 09340-06050 | NOZZLE ASSY | VS01 13 TW0 |

| 002. | [01] | 09340-06050 | NOZZLE ASSY | |

| 002. | [01] | 09340-06050 | NOZZLE ASSY |

Include in #3:

09350-07340

as HOLDER & NOZZLE SE

09350-07340

09350-07340

Include as Nozzle:

0965003060

as Nozzle

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-07340 | R2S2 13 H5 | HOLDER & NOZZLE SE | |

| MQ901765 | MITSUBISHI | HOLDER & NOZZLE SE | |

| R2S2 13 H50 | MAZDA | HOLDER & NOZZLE SE |

Information:

Fuel System

Testing 9L9263 Fuel Injection Nozzles

8S2242 Nozzle Testing Group.8S2245 Injector Cleaning Tool Group.9S7354 Torque Wrench.9S3093 Adapter.Before testing a fuel injection pump or nozzle from an engine that is misfiring or puffing black smoke, a simple check can be made to determine which cylinder is causing the difficulty.With the engine running at a speed that makes the misfiring most pronounced, momentarily loosen the fuel line nut on an injection pump sufficiently to "cut out" that cylinder. Check each cylinder in the same manner. If one is found where loosening makes no difference in the irregular operation or causes puffing of black smoke to cease, the pump and valve for only that cylinder need be tested.Exhaust port temperature, when the engine is running at low idle speed, can be an indication of injection nozzle condition. Low temperature at an exhaust manifold port, indicates no fuel to the cylinder and a possibility of a clogged nozzle. Exceptionally high exhaust port temperature may indicate excess fuel injection caused by poor fuel cut off. Do not attempt to test or disassemble nozzles without the proper service tools.Before testing, remove loose carbon from the tip with the 8S2258 Brass Wire Brush. Remove the carbon seal dam and clean the groove and the body below the groove in the same manner. Any staining in this area is normal and not detrimental to the nozzle body. Carbon accumulations should be removed, but excessive brushing will remove the coating on the nozzle. Perform all test before cleaning or adjusting a nozzle. A test may show that the nozzle can not be used again.

When testing, keep the nozzle tip directed away from the operator and into the 8S2270 Fuel Collector to contain the spray. Fuel from the spray orifices can penetrate clothing and skin causing serious infection.

Connect nozzle (4) to tester (1) using tube assembly (2) and adapter (3). The nozzle may be tightened by hand if the 1H1023 Seal is not damaged.

Always use clean Kent-Moore J23300-585 or Shell 66631 calibration oil or equivalent when testing. Dirty test oil will damage nozzle components.

Kent-Moore J2300-585 calibration oil may be purchased from Kent-Moore Corp. 1501 South Jackson St., Jackson, Michigan 49203. Shell 66631 calibration oil may be purchased from Shell Oil Company.

CONNECTING NOZZLE TO TESTER

1. 8S2267 Nozzle Tester. 2. 8S2268 Tube Assembly. 3. 9S3093 Adapter. 4. Nozzle.Opening Pressure Test

1. Close the gauge protector valve and the on-off valve. Open the pump isolator valve. Flush the nozzle by operating the tester for 10 to 15 strokes at a rate of 60 strokes per minute.2. Open the gauge protector valve. Raise the pressure slowly until the nozzle valve opens. The gauge reading may drop sharply if the valve chatters, or may stay nearly constant when the valve opens. Opening pressures should be as listed in the chart. If opening pressure is less than 2200 psi (154.7 kg/cm2), do not use the nozzle again. Lack of chatter or atomized spray during Step 2 does not indicate a faulty valve. Used nozzles that have

Testing 9L9263 Fuel Injection Nozzles

8S2242 Nozzle Testing Group.8S2245 Injector Cleaning Tool Group.9S7354 Torque Wrench.9S3093 Adapter.Before testing a fuel injection pump or nozzle from an engine that is misfiring or puffing black smoke, a simple check can be made to determine which cylinder is causing the difficulty.With the engine running at a speed that makes the misfiring most pronounced, momentarily loosen the fuel line nut on an injection pump sufficiently to "cut out" that cylinder. Check each cylinder in the same manner. If one is found where loosening makes no difference in the irregular operation or causes puffing of black smoke to cease, the pump and valve for only that cylinder need be tested.Exhaust port temperature, when the engine is running at low idle speed, can be an indication of injection nozzle condition. Low temperature at an exhaust manifold port, indicates no fuel to the cylinder and a possibility of a clogged nozzle. Exceptionally high exhaust port temperature may indicate excess fuel injection caused by poor fuel cut off. Do not attempt to test or disassemble nozzles without the proper service tools.Before testing, remove loose carbon from the tip with the 8S2258 Brass Wire Brush. Remove the carbon seal dam and clean the groove and the body below the groove in the same manner. Any staining in this area is normal and not detrimental to the nozzle body. Carbon accumulations should be removed, but excessive brushing will remove the coating on the nozzle. Perform all test before cleaning or adjusting a nozzle. A test may show that the nozzle can not be used again.

When testing, keep the nozzle tip directed away from the operator and into the 8S2270 Fuel Collector to contain the spray. Fuel from the spray orifices can penetrate clothing and skin causing serious infection.

Connect nozzle (4) to tester (1) using tube assembly (2) and adapter (3). The nozzle may be tightened by hand if the 1H1023 Seal is not damaged.

Always use clean Kent-Moore J23300-585 or Shell 66631 calibration oil or equivalent when testing. Dirty test oil will damage nozzle components.

Kent-Moore J2300-585 calibration oil may be purchased from Kent-Moore Corp. 1501 South Jackson St., Jackson, Michigan 49203. Shell 66631 calibration oil may be purchased from Shell Oil Company.

CONNECTING NOZZLE TO TESTER

1. 8S2267 Nozzle Tester. 2. 8S2268 Tube Assembly. 3. 9S3093 Adapter. 4. Nozzle.Opening Pressure Test

1. Close the gauge protector valve and the on-off valve. Open the pump isolator valve. Flush the nozzle by operating the tester for 10 to 15 strokes at a rate of 60 strokes per minute.2. Open the gauge protector valve. Raise the pressure slowly until the nozzle valve opens. The gauge reading may drop sharply if the valve chatters, or may stay nearly constant when the valve opens. Opening pressures should be as listed in the chart. If opening pressure is less than 2200 psi (154.7 kg/cm2), do not use the nozzle again. Lack of chatter or atomized spray during Step 2 does not indicate a faulty valve. Used nozzles that have