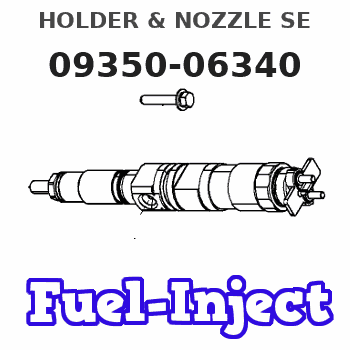

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-06340 |

Scheme ###:

| 000. | [01] | 09350-06340 | HOLDER & NOZZLE SE | RE64259 |

| 001. | [01] | 09310-06340 | HOLDER ASSY, NOZZL | |

| 001-001. | [01] | 09311-06340 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10460 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70480 | SPRING, NOZZLE HOL | |

| 001-004. | [01] | 09316-20112 | SCREW, CYLINDER | |

| 001-005. | [01] | 09316-41690 | NUT, NOZZLE RETAIN | |

| 001-006. | [1C] | 09317-51560 | WASHER | |

| 001-006. | [1C] | 09317-51550 | WASHER | |

| 001-006. | [1C] | 09317-51540 | WASHER | |

| 001-006. | [1C] | 09317-51530 | WASHER | |

| 001-006. | [1C] | 09317-51520 | WASHER | |

| 001-006. | [1C] | 09317-51510 | WASHER | |

| 001-006. | [1C] | 09317-51570 | WASHER | |

| 001-006. | [1C] | 09317-51580 | WASHER | |

| 001-006. | [1C] | 09317-51590 | WASHER | |

| 001-006. | [1C] | 09317-51600 | WASHER | |

| 001-006. | [1C] | 09317-51610 | WASHER | |

| 001-006. | [1C] | 09317-51620 | WASHER | |

| 001-006. | [1C] | 09317-51630 | WASHER | |

| 001-006. | [1C] | 09317-51640 | WASHER | |

| 001-006. | [1C] | 09317-51650 | WASHER | |

| 001-006. | [1C] | 09317-51500 | WASHER | |

| 001-006. | [1C] | 09317-51180 | WASHER | |

| 001-006. | [1C] | 09317-51170 | WASHER | |

| 001-006. | [1C] | 09317-51020 | WASHER | |

| 001-006. | [1C] | 09317-51030 | WASHER | |

| 001-006. | [1C] | 09317-51040 | WASHER | |

| 001-006. | [1C] | 09317-51050 | WASHER | |

| 001-006. | [1C] | 09317-51060 | WASHER | |

| 001-006. | [1C] | 09317-51070 | WASHER | |

| 001-006. | [1C] | 09317-51080 | WASHER | |

| 001-006. | [1C] | 09317-51090 | WASHER | |

| 001-006. | [1C] | 09317-51100 | WASHER | |

| 001-006. | [1C] | 09317-51160 | WASHER | |

| 001-006. | [1C] | 09317-51150 | WASHER | |

| 001-006. | [1C] | 09317-51140 | WASHER | |

| 001-006. | [1C] | 09317-51130 | WASHER | |

| 001-006. | [1C] | 09317-51120 | WASHER | |

| 001-006. | [1C] | 09317-51110 | WASHER | |

| 001-007. | [01] | 09322-00090 | PACKING SUB-ASSY, | |

| 001-011. | [01] | 90801-10190 | O-RING | |

| 002. | [01] | 09340-06590 | NOZZLE ASSY | RE64260 |

Include in #3:

09350-06340

as HOLDER & NOZZLE SE

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-06340 | RE64259 | HOLDER & NOZZLE SE | |

| RE64259 | JOHN DEERE | HOLDER & NOZZLE SE |

Information:

Table 1

Revision Table

Revision Summary of Changes

3 Added serial numbers. Improvement Procedure

Clean oil rail after pump failure.Reference: Refer to Special Instruction, REHS3819 for the procedure to clean the oil rail after engine failure to avoid debris in the oil system.

Use clean oil and clean filters.The life of the injector depends on the oil quality. It can be increased if good cleaning practices are performed before installing the injectors.Reference: Refer to Operation and Maintenance Manual, SEBU6250 and Operation and Maintenance Manual, SEBU6251 for direction on oil sampling intervals and optimizing engine oil life.

Illustration 1 g06207717

(1) Actuator

(2) Pump Group

(3) Valve Seat Damage Due to Debris in the Oil SystemInjector Failure Due To Damage From Debris In The Oil May Not Be A Warrantable Failure

Illustration 2 g06244961