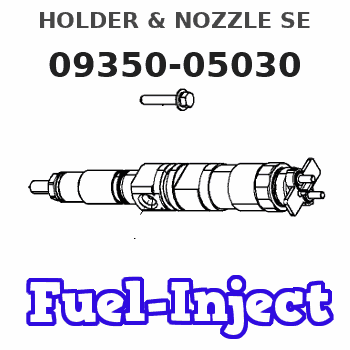

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-05030 |

| 001. | HOLDER & NOZZLE SE | 09350-05030 |

Scheme ###:

| 000. | [01] | 09350-05030 | HOLDER & NOZZLE SE | 23610-1822 |

| 000. | [01] | 09350-05030 | HOLDER & NOZZLE SE | S2361-01822 |

| 001. | [01] | 09310-05030 | HOLDER ASSY, NOZZL | S2363-01731-A |

| 001-001. | [01] | 09311-05030 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10330 | PIN, NOZZLE HOLDER | S2361-61030-A |

| 001-003. | [01] | 09312-70470 | SPRING, NOZZLE HOL | S2361-51330-A |

| 001-004. | [01] | 09313-10200 | SCREW, ADJUST | S2361-41060-A |

| 001-005. | [01] | 09313-40270 | NUT, CAP | S2362-31310-A |

| 001-006. | [01] | 09315-10510 | CONNECTOR, NOZZLE | |

| 001-007. | [01] | 09315-80010 | GASKET, INLET CONN | S2362-11070-A |

| 001-008. | [01] | 09316-41460 | NUT, NOZZLE RETAIN | S2363-31630-A |

| 001-009. | [01] | 94918-00630 | SCREW, HOLLOW | S2283-51130-A |

| 001-009. | [01] | 09507-40012 | SCREW, HOLLOW OUTL | S2283-51570-A |

| 001-010. | [01] | 09324-50052 | WASHER | S2284-71290-A |

| 001-011. | [02] | 94901-02640 | WASHER | S2284-71870-A |

| 002. | [01] | 09340-02600 | NOZZLE ASSY | S2365-01711-A |

Include in #3:

09350-05030

as HOLDER & NOZZLE SE

09350-05030

Include as Nozzle:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-05030 | 23610-1822 | HOLDER & NOZZLE SE | |

| 23610-1822 | HINO | HOLDER & NOZZLE SE | |

| S2361-01822 | HINO | HOLDER & NOZZLE SE |

Information:

Excessive engine idling time can contribute to excessive water in the crankcase oil, causing corrosion, sludge, and other problems. Excessive engine idling time can also lead to injector fouling, piston and combustion chamber deposits, corrosive damage, and increased oil consumption.

For proper selection of oil viscosity grade and oil type and/or specification, refer to this Special Publication, "Lubricant Specifications" section.Also, refer to this Special Publication, "Lubricant Viscosities" article.

Not following the recommendations found in the “Lubricant Viscosities for Ambient Temperatures” table and associated footnotes can lead to reduced performance and engine failure.

Do NOT use only the oil viscosities when determining the recommended oil for an engine compartment. The oil type (performance requirements) MUST also be used.

For easier cold weather starting, make sure that all of the components of the engine electrical system are properly maintained. All electrical wiring and connections should be free of the following: fraying, damaged insulation and corrosion. Batteries should be kept fully charged and warm. The batteries and the battery cables must be sized properly for the application.Various starting aids are available in order to assist with cold engine starts in low temperature conditions. Follow the recommendations that are provided by the manufacturer of the starting aid. Refer to the foreword section of this Special Publication, "Aftermarket Products and Warranty".For additional information concerning cold-weather operation, refer to this Special Publication, "Fuel Specifications" section. Also refer to this Special Publication, "Cooling System Specifications" section.Before attempting to start the engine, make sure that the oil in the engine is fluid enough to flow. Check the oil by removing the dipstick. If the oil will drip from the dipstick, then the oil should be fluid enough to allow the engine to start. Do not use oil that has been diluted with kerosene. Kerosene will evaporate in the engine. and cause the oil to thicken. Kerosene will cause swelling and softening of the silicone seals. Kerosene will dilute the oil additives. Dilution of the oil additives will reduce the performance, and reduce the engine protection that the additives provide.If the viscosity of the oil is changed for colder weather, also change the filter element. If the filter is not changed, the filter element and the filter housing can become a solid mass. After you change the oil, operate the engine in order to circulate the thinner oil.When you start a cold-soaked engine or when you operate an engine in ambient temperatures that are below −18°C (0°F), use base oils that can flow in low temperatures. These multigrade oils have lubricant viscosity grade of SAE 0W or of SAE 5W. An example of viscosity grade is SAE 5W-40.When you start a cold-soaked engine or when you operate an engine in ambient temperatures that are below −30°C (−22°F), use synthetic basestock multigrade oil. The oil should have a lubricant viscosity grade of SAE 0W or SAE 5W. Use oil with a pour point that is lower than −40°C (−40°F).Note: Use the highest oil viscosity grade that is allowed for the ambient temperature