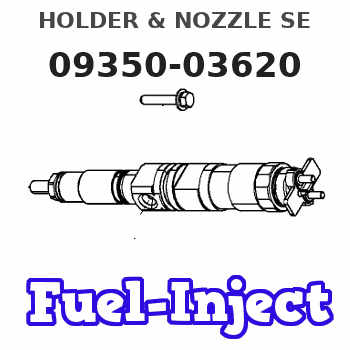

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-03620 |

Scheme ###:

| 000. | [01] | 09350-03620 | HOLDER & NOZZLE SE | 62121-13600 |

| 001. | [01] | 09310-03620 | HOLDER ASSY, NOZZL | 62121-13610 |

| 001-001. | [01] | 09311-03620 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10490 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70390 | SPRING, NOZZLE HOL | |

| 001-004. | [01] | 09315-00252 | CONNECTOR SUB-ASSY | 62121-13131 |

| 001-005. | [01] | 09316-41160 | NUT, NOZZLE RETAIN | |

| 001-006. | [1C] | 09317-51620 | WASHER | |

| 001-006. | [1C] | 09317-51610 | WASHER | |

| 001-006. | [1C] | 09317-51600 | WASHER | |

| 001-006. | [1C] | 09317-51590 | WASHER | |

| 001-006. | [1C] | 09317-51580 | WASHER | |

| 001-006. | [1C] | 09317-51570 | WASHER | |

| 001-006. | [1C] | 09317-51560 | WASHER | |

| 001-006. | [1C] | 09317-51550 | WASHER | |

| 001-006. | [1C] | 09317-51630 | WASHER | |

| 001-006. | [1C] | 09317-51640 | WASHER | |

| 001-006. | [1C] | 09317-51650 | WASHER | |

| 001-006. | [1C] | 09317-53950 | WASHER | |

| 001-006. | [1C] | 09317-53940 | WASHER | |

| 001-006. | [1C] | 09317-53930 | WASHER | |

| 001-006. | [1C] | 09317-53920 | WASHER | |

| 001-006. | [1C] | 09317-53910 | WASHER | |

| 001-006. | [1C] | 09317-53900 | WASHER | |

| 001-006. | [1C] | 09317-53890 | WASHER | |

| 001-006. | [1C] | 09317-53880 | WASHER | |

| 001-006. | [1C] | 09317-51540 | WASHER | |

| 001-006. | [1C] | 09317-51530 | WASHER | |

| 001-006. | [1C] | 09317-51520 | WASHER | |

| 001-006. | [1C] | 09317-51090 | WASHER | |

| 001-006. | [1C] | 09317-51080 | WASHER | |

| 001-006. | [1C] | 09317-51070 | WASHER | |

| 001-006. | [1C] | 09317-51060 | WASHER | |

| 001-006. | [1C] | 09317-51050 | WASHER | |

| 001-006. | [1C] | 09317-51040 | WASHER | |

| 001-006. | [1C] | 09317-51030 | WASHER | |

| 001-006. | [1C] | 09317-51020 | WASHER | |

| 001-006. | [1C] | 09317-51100 | WASHER | |

| 001-006. | [1C] | 09317-51110 | WASHER | |

| 001-006. | [1C] | 09317-51120 | WASHER | |

| 001-006. | [1C] | 09317-51510 | WASHER | |

| 001-006. | [1C] | 09317-51500 | WASHER | |

| 001-006. | [1C] | 09317-51180 | WASHER | |

| 001-006. | [1C] | 09317-51170 | WASHER | |

| 001-006. | [1C] | 09317-51160 | WASHER | |

| 001-006. | [1C] | 09317-51150 | WASHER | |

| 001-006. | [1C] | 09317-51140 | WASHER | |

| 001-006. | [1C] | 09317-51130 | WASHER | |

| 001-007. | [01] | 09322-00050 | PACKING SUB-ASSY, | |

| 002. | [01] | 09340-02090 | NOZZLE ASSY | 62121-13620 |

Include in #3:

09350-03620

as HOLDER & NOZZLE SE

Include as Nozzle:

1910004000

as Nozzle

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-03620 | 62121-1360 | HOLDER & NOZZLE SE | |

| 62121-13600 | KOMATSU | HOLDER & NOZZLE SE |

Information:

Engine Will Not Start Step 1

Install the Electronic Control Analyzer and Programmer (ECAP) or the Digital Diagnostic Service Tool (DDT). See Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913.Step 2

Electronic Self Check. Check the electronics diagnostic lamp on the dash to determine if there are any faults in the engine electronics system. Repair or replace parts as needed. Refer to Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913.Step 3

Check Cranking Speed Of Crankshaft. Using the ECAP or DDT, check the speed of the crankshaft while the starter is cranking. If the crankshaft speed is below 250 rpm, then proceed to item 4. If the crankshaft speed is above 250 rpm, then proceed to item 5.Step 4

Possible Causes Of Low Cranking Speed:1. Low Battery VoltageCheck battery voltage. If the voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If the battery will not hold a charge, load test the battery. Use the 6V4930 Battery Load Tester and make reference to Special Instruction, Form No. SEHS8268 for complete information on use of the 6V4930 Battery Load Tester.2. Defective Cable, Battery To Starter, Or Defective ConnectionWith ignition switch in the START position, check the voltage at the connection of the battery cable to the starter. If there is no voltage, or if the voltage is low at this connection and there is good voltage at the battery, check for a defective cable or connection between the battery and the starter.3. Oil Too Thick For Free Crankshaft RotationRefer to the 3176 Truck Engine Operation And Maintenance Manual, Form No. SEBU6163 for the correct SAE grade oils for the ambient temperatures at which the engine is being operated. At temperatures below -23° C (-10° F), it may be necessary to warm the oil for free crankshaft rotation.4. Defective Starter MotorRemove and test. Make repairs as necessary or install a new starter motor.5. Extra Outside Loads.Damage to the power take-off equipment (if so equipped) and/or transmission can put extra load on the engine and prevent free rotation of the crankshaft. To check, disconnect the transmission and power takeoff, and start the engine.6. Transmission Or Power Take-off ProblemSee the Truck Manufacturer's Service Manual.7. Internal Engine ProblemDisassemble the engine and check all components for damage. See 3176 Diesel Truck Engine Disassembly And Assembly, Form No. SENR3914.Step 5

Can Exhaust Smoke Be Seen While Starting?If exhaust smoke can be seen while starting the engine, then proceed to item 6. If exhaust cannot be seen while starting the engine, then proceed to item 7.Step 6

A. Possible Causes-Engine Will Not StartCold Outside TemperaturesIt may be necessary to use starting aids, or to heat engine oil or coolant at temperatures below 0° C (32° F).B. Air In Fuel SystemWith air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen the highest drain plug

Install the Electronic Control Analyzer and Programmer (ECAP) or the Digital Diagnostic Service Tool (DDT). See Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913.Step 2

Electronic Self Check. Check the electronics diagnostic lamp on the dash to determine if there are any faults in the engine electronics system. Repair or replace parts as needed. Refer to Electronic Troubleshooting, 3176 Diesel Truck Engine, Form No. SENR3913.Step 3

Check Cranking Speed Of Crankshaft. Using the ECAP or DDT, check the speed of the crankshaft while the starter is cranking. If the crankshaft speed is below 250 rpm, then proceed to item 4. If the crankshaft speed is above 250 rpm, then proceed to item 5.Step 4

Possible Causes Of Low Cranking Speed:1. Low Battery VoltageCheck battery voltage. If the voltage is less than 8 volts for a 12 volt system, or 16 volts for a 24 volt system, put a charge to the battery. If the battery will not hold a charge, load test the battery. Use the 6V4930 Battery Load Tester and make reference to Special Instruction, Form No. SEHS8268 for complete information on use of the 6V4930 Battery Load Tester.2. Defective Cable, Battery To Starter, Or Defective ConnectionWith ignition switch in the START position, check the voltage at the connection of the battery cable to the starter. If there is no voltage, or if the voltage is low at this connection and there is good voltage at the battery, check for a defective cable or connection between the battery and the starter.3. Oil Too Thick For Free Crankshaft RotationRefer to the 3176 Truck Engine Operation And Maintenance Manual, Form No. SEBU6163 for the correct SAE grade oils for the ambient temperatures at which the engine is being operated. At temperatures below -23° C (-10° F), it may be necessary to warm the oil for free crankshaft rotation.4. Defective Starter MotorRemove and test. Make repairs as necessary or install a new starter motor.5. Extra Outside Loads.Damage to the power take-off equipment (if so equipped) and/or transmission can put extra load on the engine and prevent free rotation of the crankshaft. To check, disconnect the transmission and power takeoff, and start the engine.6. Transmission Or Power Take-off ProblemSee the Truck Manufacturer's Service Manual.7. Internal Engine ProblemDisassemble the engine and check all components for damage. See 3176 Diesel Truck Engine Disassembly And Assembly, Form No. SENR3914.Step 5

Can Exhaust Smoke Be Seen While Starting?If exhaust smoke can be seen while starting the engine, then proceed to item 6. If exhaust cannot be seen while starting the engine, then proceed to item 7.Step 6

A. Possible Causes-Engine Will Not StartCold Outside TemperaturesIt may be necessary to use starting aids, or to heat engine oil or coolant at temperatures below 0° C (32° F).B. Air In Fuel SystemWith air in the fuel system, the engine will normally be difficult to start, run rough, and release a large amount of white smoke. If the engine will not start, loosen the highest drain plug