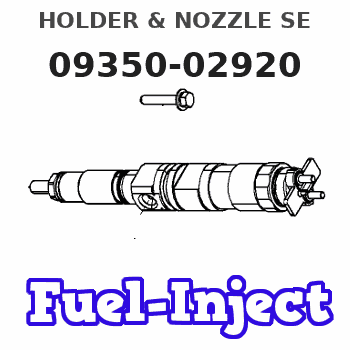

Information holder & nozzle se

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Heavy Equipment Parts & Accessories – Durable High-Performance Replacement Parts 4Pcs Fuel Injector 093500-2920 093500-2860 093500-2340 for Denso Engine Model-Z59-FX4075

Generic ✔ Premium Quality & Durability – Manufactured with high-grade materials to ensure long-lasting performance in demanding industrial and construction environments. || ✔ Wide Compatibility – Designed to fit various heavy equipment brands and models, including excavators, loaders, bulldozers, and more for seamless installation. || ✔ Enhanced Performance & Efficiency – Engineered to withstand extreme conditions, reducing downtime and increasing the lifespan of your machinery. || ✔ Easy Installation & Maintenance – Precise fitment and hassle-free setup make replacements quick and efficient, saving time and labor costs. || ✔ Reliable Supplier – Sourced from trusted manufacturers with strict quality control standards, ensuring timely superior product reliability.

Generic ✔ Premium Quality & Durability – Manufactured with high-grade materials to ensure long-lasting performance in demanding industrial and construction environments. || ✔ Wide Compatibility – Designed to fit various heavy equipment brands and models, including excavators, loaders, bulldozers, and more for seamless installation. || ✔ Enhanced Performance & Efficiency – Engineered to withstand extreme conditions, reducing downtime and increasing the lifespan of your machinery. || ✔ Easy Installation & Maintenance – Precise fitment and hassle-free setup make replacements quick and efficient, saving time and labor costs. || ✔ Reliable Supplier – Sourced from trusted manufacturers with strict quality control standards, ensuring timely superior product reliability.

Components :

| 001. | HOLDER & NOZZLE SE | 09350-02920 |

| 002. | HOLDER & NOZZLE SE | 09350-02630 |

Scheme ###:

| 000. | [01] | 09350-02920 | HOLDER & NOZZLE SE | 23600-59035 |

| 001. | [01] | 09350-02630 | HOLDER & NOZZLE SE | 23600-54060 |

| 002. | [01] | 09313-30161 | GASKET | 11177-54011 |

Include in #3:

09350-02920

as HOLDER & NOZZLE SE

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-02920 | 23600-5903 | HOLDER & NOZZLE SE | |

| 23600-59035 | TOYOTA | HOLDER & NOZZLE SE |

Information:

Daily

Walk-Around Inspection - Inspect engine, radiator and generator/control panel for dirt & debris, moisture, foreign objects, loose or broken fittings and wires, guards and components. Repair as necessary Engine Crankcase - Check oil level Cooling System - Check coolant level, Check for proper operation of coolant heater Air Cleaner Indicator - Check Air Starting Motor (If Equipped) - Check level; Drain water SR4 Generator - Check frequency (rpm) and generated voltage for proper settings and stability; record readingsEvery 250 Hours or 25 000 L (6500 gal) of Fuel*

Scheduled Oil Sampling (S O S)** - Obtain Engine Oil and Filters - Replace Fuel System - Drain water & sediment from tank; Replace final filter/Clean primary filter Cooling System - Test for coolant additive concentration; Add liquid coolant additive; Clean radiator fins Crankcase Breathers - Clean Batteries - Clean/Inspect and check electrolyte level Belts, Hoses and Clamps - Inspect/Check Engine Air Cleaners - Clean/Replace SR4 Generator - Check space heater (if equipped) Engine Speed Sensors (Magnetic Pickup) - Inspect/Clean at first oil change Valve Lash** - Check/Adjust at first oil changeEvery 1000 Hours or 100 000 L (26,000 gal) of Fuel*

Engine Protection Controls - Inspect for proper operation SR4 Generator - Check windings and record megohmeter readings (Refer to SEHS9124)Every 3000 Hours or 300 000 L (78,000 gal) of Fuel*

Engine Valve Lash - Check/Adjust, Inspect valve rotators Turbocharger - Inspect for proper operation Engine Mounts and Crankshaft Vibration Damper - Inspect/Check Cooling System - Clean/Flush/Change coolant and replace thermostat SR4 Generator - Lubricate bearings (Refer to SEBU6150) PAR Analysis - ObtainEvery 5000 Hours or 500 000 L (130,000 gal) of Fuel*

Fuel Injection Nozzles - Test/Exchange Starting Motor and Alternator - Inpect for proper operation Turbochargers - Inspect/Rebuild or Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Engine Speed Sensors (Magnetic Pickup) - Inspect/CleanOverhaul Every 10,000 Hours or 1 000 000 L (260,000 gal) of Fuel*

Cylinder Heads, Oil Pump, Fuel Transfer Pump - Inspect/Rebuild or Exchange Piston Rings, Main Bearings, Rod Bearings, Valve Rotators and Crankshaft Seals - Install new Fuel Injection Nozzles and Fuel Injection Pump - Test Connecting Rods, Pistons, Cylinder Liners, Crankshaft, Camshaft, Cam Bearings, Damper, Fuel Pump Camshaft, Cam Followers and Fuel Racks - Inspect/Replace Gear Train Gears & Bushings and Driven Unit Alignment Oil Cooler and Aftercooler Core - Clean/Test Coolant Analysis - Obtain SR4 Generator - Inspect/Clean windings*First Perform Previous Service Hour Items Caterpillar suggests that fuel consumption be used as the preferred method of determining maintenance intervals. Fuel consumption/Hours to Overhaul interval will vary depending on the proper application of your engine rating and maintenance practices.

Walk-Around Inspection - Inspect engine, radiator and generator/control panel for dirt & debris, moisture, foreign objects, loose or broken fittings and wires, guards and components. Repair as necessary Engine Crankcase - Check oil level Cooling System - Check coolant level, Check for proper operation of coolant heater Air Cleaner Indicator - Check Air Starting Motor (If Equipped) - Check level; Drain water SR4 Generator - Check frequency (rpm) and generated voltage for proper settings and stability; record readingsEvery 250 Hours or 25 000 L (6500 gal) of Fuel*

Scheduled Oil Sampling (S O S)** - Obtain Engine Oil and Filters - Replace Fuel System - Drain water & sediment from tank; Replace final filter/Clean primary filter Cooling System - Test for coolant additive concentration; Add liquid coolant additive; Clean radiator fins Crankcase Breathers - Clean Batteries - Clean/Inspect and check electrolyte level Belts, Hoses and Clamps - Inspect/Check Engine Air Cleaners - Clean/Replace SR4 Generator - Check space heater (if equipped) Engine Speed Sensors (Magnetic Pickup) - Inspect/Clean at first oil change Valve Lash** - Check/Adjust at first oil changeEvery 1000 Hours or 100 000 L (26,000 gal) of Fuel*

Engine Protection Controls - Inspect for proper operation SR4 Generator - Check windings and record megohmeter readings (Refer to SEHS9124)Every 3000 Hours or 300 000 L (78,000 gal) of Fuel*

Engine Valve Lash - Check/Adjust, Inspect valve rotators Turbocharger - Inspect for proper operation Engine Mounts and Crankshaft Vibration Damper - Inspect/Check Cooling System - Clean/Flush/Change coolant and replace thermostat SR4 Generator - Lubricate bearings (Refer to SEBU6150) PAR Analysis - ObtainEvery 5000 Hours or 500 000 L (130,000 gal) of Fuel*

Fuel Injection Nozzles - Test/Exchange Starting Motor and Alternator - Inpect for proper operation Turbochargers - Inspect/Rebuild or Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Engine Speed Sensors (Magnetic Pickup) - Inspect/CleanOverhaul Every 10,000 Hours or 1 000 000 L (260,000 gal) of Fuel*

Cylinder Heads, Oil Pump, Fuel Transfer Pump - Inspect/Rebuild or Exchange Piston Rings, Main Bearings, Rod Bearings, Valve Rotators and Crankshaft Seals - Install new Fuel Injection Nozzles and Fuel Injection Pump - Test Connecting Rods, Pistons, Cylinder Liners, Crankshaft, Camshaft, Cam Bearings, Damper, Fuel Pump Camshaft, Cam Followers and Fuel Racks - Inspect/Replace Gear Train Gears & Bushings and Driven Unit Alignment Oil Cooler and Aftercooler Core - Clean/Test Coolant Analysis - Obtain SR4 Generator - Inspect/Clean windings*First Perform Previous Service Hour Items Caterpillar suggests that fuel consumption be used as the preferred method of determining maintenance intervals. Fuel consumption/Hours to Overhaul interval will vary depending on the proper application of your engine rating and maintenance practices.