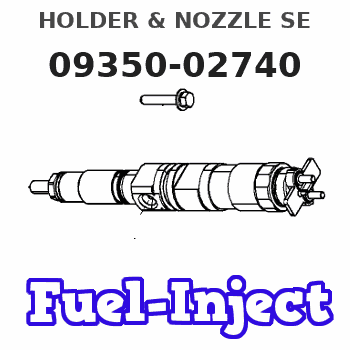

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-02740 |

Scheme ###:

| 000. | [01] | 09350-02740 | HOLDER & NOZZLE SE | 23610-1390C |

| 001. | [01] | 09310-02740 | HOLDER ASSY, NOZZL | 23630-1320A |

| 001-001. | [01] | 09311-02740 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10330 | PIN, NOZZLE HOLDER | S2361-61030-A |

| 001-003. | [01] | 09312-70280 | SPRING, NOZZLE HOL | S2361-51190-A |

| 001-004. | [01] | 09313-10200 | SCREW, ADJUST | S2361-41060-A |

| 001-005. | [01] | 09313-40270 | NUT, CAP | S2362-31310-A |

| 001-006. | [01] | 09315-10340 | CONNECTOR, NOZZLE | 23611-1190A |

| 001-007. | [01] | 09315-80010 | GASKET, INLET CONN | S2362-11070-A |

| 001-008. | [01] | 09316-41090 | NUT, NOZZLE RETAIN | 23633-1250A |

| 001-009. | [01] | 94918-00630 | SCREW, HOLLOW | S2283-51130-A |

| 001-010. | [01] | 09324-50052 | WASHER | S2284-71290-A |

| 001-011. | [02] | 94901-02640 | WASHER | S2284-71870-A |

| 002. | [01] | 09340-01570 | NOZZLE ASSY | S2365-01340-A |

Include in #3:

09350-02740

as HOLDER & NOZZLE SE

Include as Nozzle:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-02740 | 23610-1390 | HOLDER & NOZZLE SE | |

| 23610-1390C | HINO | HOLDER & NOZZLE SE |

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner - Check service indicator/Service air cleaner when needed Air Starter (If Equipped) - Check lubricator oil level Clutch (If Equipped) - Check/Adjust/Lubricate Marine Transmission - Check oil levelEvery 3800 L (1000 gal) of Fuel or 50 Hours

Zinc Rods - Inspect/ReplaceEvery 19,000 L (5,000 gal) Of Fuel Or 250 Hours or Yearly

Fuel System - Clean primary fuel filter (if equipped)/Replace final fuel filter Fuel Tank - Drain water and sediment Cooling System (Conventional HD Coolant Only) - Test for SCA concentration OR obtain Level I coolant analysis/Add SCA if necessary Air Cleaner - Clean/Replace air filter elements Belts - Check/Adjust/Replace Hoses and Clamps - Inspect/Replace Batteries - Clean/Check (if required)First 38,000 L (10,000 gal) of Fuel or 500 Hours

Valve Lash - Check/Adjust (at the first oil change interval)Every 38,000 L (10,000 gal) of Fuel or 500 Hours

Scheduled Oil Sampling (S O S) - Obtain Sample and analysis Engine Crankcase - Replace oil and filter(s) Crankcase Breathers - CleanEvery 76,000 L (20,000 gal) Of Fuel Or 1000 Hours

Engine Protection Devices - Inspect/Check Magnetic Pickup - Inspect/AdjustEvery 227,500 L (60,000 gal) Of Fuel Or 3000 Hours

Water Temperature Regulators (Thermostats) - Replace Cooling System (Extended Life Coolant Only) - Add Extender1 Cooling System (Conventional HD Coolant Only) - Drain/Clean/Replace coolant Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect Valve Lash, Valve Rotators - Check/Adjust Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust PAR Analysis - ObtainEvery 379,000 L (100,000 gal) Of Fuel Or 5000 Hours

Fuel Injection Nozzles - Test/Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Raw/Sea Water Pump - Inspect/Rebuild or Exchange Alternator - Inspect/Rebuild or Exchange Starting Motor - Inspect/Rebuild or Exchange Air Compressor (If Equipped) - Inspect/Rebuild or Exchange Turbocharger - Clean/Inspect/CheckEvery 6000 Hours Or Four Years

Cooling System (Extended Life Coolant Only) - Drain/Flush/Replace CoolantOverhaul

Overhaul Considerations1If a commercial HD coolant/antifreeze meeting ASTM D4985 specifications is used, or if a mixture of commercial SCA and water is used, this maintenance should be performed at a maximum of One Year.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner - Check service indicator/Service air cleaner when needed Air Starter (If Equipped) - Check lubricator oil level Clutch (If Equipped) - Check/Adjust/Lubricate Marine Transmission - Check oil levelEvery 3800 L (1000 gal) of Fuel or 50 Hours

Zinc Rods - Inspect/ReplaceEvery 19,000 L (5,000 gal) Of Fuel Or 250 Hours or Yearly

Fuel System - Clean primary fuel filter (if equipped)/Replace final fuel filter Fuel Tank - Drain water and sediment Cooling System (Conventional HD Coolant Only) - Test for SCA concentration OR obtain Level I coolant analysis/Add SCA if necessary Air Cleaner - Clean/Replace air filter elements Belts - Check/Adjust/Replace Hoses and Clamps - Inspect/Replace Batteries - Clean/Check (if required)First 38,000 L (10,000 gal) of Fuel or 500 Hours

Valve Lash - Check/Adjust (at the first oil change interval)Every 38,000 L (10,000 gal) of Fuel or 500 Hours

Scheduled Oil Sampling (S O S) - Obtain Sample and analysis Engine Crankcase - Replace oil and filter(s) Crankcase Breathers - CleanEvery 76,000 L (20,000 gal) Of Fuel Or 1000 Hours

Engine Protection Devices - Inspect/Check Magnetic Pickup - Inspect/AdjustEvery 227,500 L (60,000 gal) Of Fuel Or 3000 Hours

Water Temperature Regulators (Thermostats) - Replace Cooling System (Extended Life Coolant Only) - Add Extender1 Cooling System (Conventional HD Coolant Only) - Drain/Clean/Replace coolant Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect Valve Lash, Valve Rotators - Check/Adjust Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust PAR Analysis - ObtainEvery 379,000 L (100,000 gal) Of Fuel Or 5000 Hours

Fuel Injection Nozzles - Test/Exchange Jacket Water Pump - Inspect/Rebuild or Exchange Raw/Sea Water Pump - Inspect/Rebuild or Exchange Alternator - Inspect/Rebuild or Exchange Starting Motor - Inspect/Rebuild or Exchange Air Compressor (If Equipped) - Inspect/Rebuild or Exchange Turbocharger - Clean/Inspect/CheckEvery 6000 Hours Or Four Years

Cooling System (Extended Life Coolant Only) - Drain/Flush/Replace CoolantOverhaul

Overhaul Considerations1If a commercial HD coolant/antifreeze meeting ASTM D4985 specifications is used, or if a mixture of commercial SCA and water is used, this maintenance should be performed at a maximum of One Year.