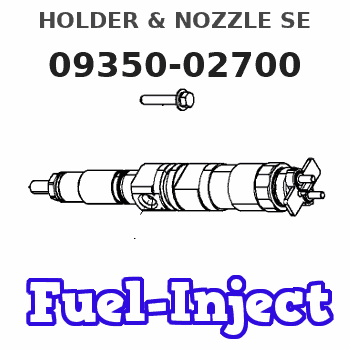

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-02700 |

Scheme ###:

| 000. | [01] | 09350-02700 | HOLDER & NOZZLE SE | 42614-00301 |

| 001. | [01] | 09310-02700 | HOLDER ASSY, NOZZL | |

| 001-001. | [01] | 09311-02700 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10330 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70270 | SPRING, NOZZLE HOL | |

| 001-004. | [01] | 09313-10200 | SCREW, ADJUST | |

| 001-005. | [01] | 09313-40290 | NUT, CAP | |

| 001-006. | [01] | 09315-10380 | CONNECTOR, NOZZLE | |

| 001-007. | [01] | 09315-80010 | GASKET, INLET CONN | EZ0087405 |

| 001-008. | [01] | 09316-40781 | NUT, NOZZLE RETAIN | |

| 001-009. | [01] | 94918-00152 | SCREW, HOLLOW | 00918-00152 |

| 001-010. | [01] | 09324-50052 | WASHER | ME022312 |

| 001-011. | [02] | 94901-81020 | WASHER, COPPER PLA | 94901-81020 |

| 002. | [01] | 09340-01560 | NOZZLE ASSY | 42614-00401 |

Include in #3:

09350-02700

as HOLDER & NOZZLE SE

Include as Nozzle:

0930000700

as Nozzle

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-02700 | 42614-0030 | HOLDER & NOZZLE SE | |

| 42614-00301 | MITSUBISHI | HOLDER & NOZZLE SE |

Information:

Air Compressor

Inspect/Rebuild or Exchange

Do not disconnect the air line from the air compressor governor without purging the air brake and auxiliary air systems.Failure to purge the air brake and auxiliary air systems before removing the air compressor and/or air lines could cause personal injury.

Inspect the air compressor as instructed by the truck/vehicle manufacturers' instructions or for more information on how to check your air compressor, refer to the Service Manual for this engine.If you decide to inspect your air compressor, be sure to observe the following actions.* Release the air pressure in the air tank until the air pressure is zero.* Visually check for fluid leaks and listen for air leaks.* Remove discharge fittings and inspect compressor discharge port and discharge line for excessive carbon deposits. The discharge line must be cleaned or replaced and the compressor checked more thoroughly if there is excessive carbon build-up in either the discharge line or compressor discharge port.For more information on how to check your air compressor, refer to the Engine Service Manual.

DO NOT store alcohol in the cab. Alcohol is highly flammable and toxic.

In arctic conditions, use alcohol injection to prevent moisture from freezing in the air system.Removal and Installation

Refer to the established procedure in the Service Manual to Remove and Install the Air Compressor, or contact Caterpillar for assistance.Water Pump

Inspect/Replace

* Inspect the water pump for leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract.Check for unusual noise and/or wobbling of the pulley bearings.Removal and Installation

If the assembly should require disassembly, refer to the established procedure in the Service Manual to Remove and Install the Water Pump, or contact Caterpillar for assistance.Fan Drive & Water Pump Belt Tightener Assembly

Inspect/Check Fan Drive

Inspect the fan drive pulley assembly for excessive looseness or wobble. It should be difficult to detect movement of the shaft in the bearing. If the shaft is loose in the bearings, an inspection of the internal components should be made.The bearing end play should be 0.03 to 0.23 mm (.001 to .009 inch). The radial play should be no greater than 0.13 mm (.005 inch).If the assembly should require disassembly, refer to the Service Manual for the procedure.Inspect/Check Water Pump Belt Tightener Assembly

Inspect the belt tightener assembly. Check for unusual noise and/or wobbling of the pulley bearings.If the assembly should require disassembly, refer to the Service Manual for the procedure.Starting Motor

Inspect/Check for Proper Operation

Caterpillar recommends a scheduled inspection/check of your starting motor. Refer to the established procedure for inspection and specifications in the Service Manual, or contact Caterpillar for assistance.Alternator

Inspect/Check

Caterpillar recommends a scheduled inspection/check of your alternator.Refer to the established procedure for inspection and specifications in the Service Manual, or contact Caterpillar for assistance.Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under

Inspect/Rebuild or Exchange

Do not disconnect the air line from the air compressor governor without purging the air brake and auxiliary air systems.Failure to purge the air brake and auxiliary air systems before removing the air compressor and/or air lines could cause personal injury.

Inspect the air compressor as instructed by the truck/vehicle manufacturers' instructions or for more information on how to check your air compressor, refer to the Service Manual for this engine.If you decide to inspect your air compressor, be sure to observe the following actions.* Release the air pressure in the air tank until the air pressure is zero.* Visually check for fluid leaks and listen for air leaks.* Remove discharge fittings and inspect compressor discharge port and discharge line for excessive carbon deposits. The discharge line must be cleaned or replaced and the compressor checked more thoroughly if there is excessive carbon build-up in either the discharge line or compressor discharge port.For more information on how to check your air compressor, refer to the Engine Service Manual.

DO NOT store alcohol in the cab. Alcohol is highly flammable and toxic.

In arctic conditions, use alcohol injection to prevent moisture from freezing in the air system.Removal and Installation

Refer to the established procedure in the Service Manual to Remove and Install the Air Compressor, or contact Caterpillar for assistance.Water Pump

Inspect/Replace

* Inspect the water pump for leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract.Check for unusual noise and/or wobbling of the pulley bearings.Removal and Installation

If the assembly should require disassembly, refer to the established procedure in the Service Manual to Remove and Install the Water Pump, or contact Caterpillar for assistance.Fan Drive & Water Pump Belt Tightener Assembly

Inspect/Check Fan Drive

Inspect the fan drive pulley assembly for excessive looseness or wobble. It should be difficult to detect movement of the shaft in the bearing. If the shaft is loose in the bearings, an inspection of the internal components should be made.The bearing end play should be 0.03 to 0.23 mm (.001 to .009 inch). The radial play should be no greater than 0.13 mm (.005 inch).If the assembly should require disassembly, refer to the Service Manual for the procedure.Inspect/Check Water Pump Belt Tightener Assembly

Inspect the belt tightener assembly. Check for unusual noise and/or wobbling of the pulley bearings.If the assembly should require disassembly, refer to the Service Manual for the procedure.Starting Motor

Inspect/Check for Proper Operation

Caterpillar recommends a scheduled inspection/check of your starting motor. Refer to the established procedure for inspection and specifications in the Service Manual, or contact Caterpillar for assistance.Alternator

Inspect/Check

Caterpillar recommends a scheduled inspection/check of your alternator.Refer to the established procedure for inspection and specifications in the Service Manual, or contact Caterpillar for assistance.Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under