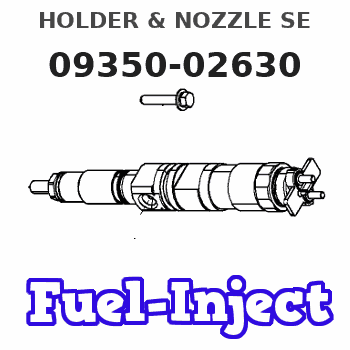

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-02630 |

Scheme ###:

| 000. | [01] | 09350-02630 | HOLDER & NOZZLE SE | 23600-54060 |

| 001. | [01] | 09310-02630 | HOLDER ASSY, NOZZL | |

| 001-001. | [01] | 09311-02630 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10030 | PIN, NOZZLE HOLDER | 23619-46010 |

| 001-003. | [01] | 09312-70301 | SPRING, NOZZLE HOL | 23618-54020 |

| 001-004. | [01] | 09316-40971 | NUT, NOZZLE RETAIN | 23624-54040 |

| 001-005. | [01] | 09317-40011 | DISTANCE PIECE | 23629-46010 |

| 001-006. | [1C] | 09317-50120 | WASHER | 23643-46010 |

| 001-006. | [1C] | 09317-50130 | WASHER | 23644-46010 |

| 001-006. | [1C] | 09317-50140 | WASHER | 23645-46010 |

| 001-006. | [1C] | 09317-50150 | WASHER | 23646-46010 |

| 001-006. | [1C] | 09317-50160 | WASHER | 23647-46010 |

| 001-006. | [1C] | 09317-50170 | WASHER | 23648-46010 |

| 001-006. | [1C] | 09317-50180 | WASHER | 23649-46010 |

| 001-006. | [1C] | 09317-50190 | WASHER | 23651-46010 |

| 001-006. | [1C] | 09317-50200 | WASHER | DES24-00117 |

| 001-006. | [1C] | 09317-50110 | WASHER | 23642-46010 |

| 001-006. | [1C] | 09317-50100 | WASHER | 23641-46010 |

| 001-006. | [1C] | 09317-50010 | WASHER | 23631-46010 |

| 001-006. | [1C] | 09317-50020 | WASHER | 23632-46010 |

| 001-006. | [1C] | 09317-50030 | WASHER | 23633-46010 |

| 001-006. | [1C] | 09317-50040 | WASHER | DMF24-53430 |

| 001-006. | [1C] | 09317-50050 | WASHER | 23635-46010 |

| 001-006. | [1C] | 09317-50060 | WASHER | 23636-46010 |

| 001-006. | [1C] | 09317-50070 | WASHER | DMF24-53430 |

| 001-006. | [1C] | 09317-50080 | WASHER | 23638-46010 |

| 001-006. | [1C] | 09317-50090 | WASHER | 23639-46010 |

| 001-007. | [01] | 09324-50040 | WASHER | 23654-46010 |

| 001-009. | [01] | 94905-02480 | NUT, HEXAGON | 23628-46010 |

| 002. | [01] | 09340-01330 | NOZZLE ASSY | 23620-54040 |

Include in #3:

09350-02630

as HOLDER & NOZZLE SE

Include as Nozzle:

0960001490

as Nozzle

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-02630 | 23600-5406 | HOLDER & NOZZLE SE | |

| 23600-54060 | TOYOTA | HOLDER & NOZZLE SE |

Information:

Inspection and Maintenance Agreements

Your Caterpillar dealer can establish an Inspection and Preventive Maintenance Program for your generator set to provide maximum reliability, increased engine and generator life, and minimize expensive repairs. Contact your Caterpillar dealer for details.General Recommendations

Safety

The stop-manual-automatic switch on the cranking panel must be set at STOP position when performing maintenance or repair work on a standby generator set. This prevents the unit from starting if a power failure or voltage drop should occur while working on the unit.To prevent personal injury due to accidental starting of the engine, disconnect the batteries or disable the starting system before doing maintenance or repair work.Lock out all switch gear and automatic transfer switches associated with the generator while performing any generator maintenance or repairs. Make sure no shock hazard exists.Failure to comply could result in personal injury or death.

Always make repairs with the engine stopped and the starting system disabled. When servicing the generator, make sure that switch gear and automatic transfer switches will not present a shock hazard. Lock them out on the generator being serviced.Record Keeping

Maintain a log or record keeping system to document all gauge readings, problems, repairs, and maintenance performed on the equipment.Space Heaters

Moisture is a natural enemy of generators and all electrical equipment. Every effort must be made to keep the generator as dry as possible. Space heaters should be operated inside the generator when it is not in use to maintain the integrity of the generator windings.

Your Caterpillar dealer can establish an Inspection and Preventive Maintenance Program for your generator set to provide maximum reliability, increased engine and generator life, and minimize expensive repairs. Contact your Caterpillar dealer for details.General Recommendations

Safety

The stop-manual-automatic switch on the cranking panel must be set at STOP position when performing maintenance or repair work on a standby generator set. This prevents the unit from starting if a power failure or voltage drop should occur while working on the unit.To prevent personal injury due to accidental starting of the engine, disconnect the batteries or disable the starting system before doing maintenance or repair work.Lock out all switch gear and automatic transfer switches associated with the generator while performing any generator maintenance or repairs. Make sure no shock hazard exists.Failure to comply could result in personal injury or death.

Always make repairs with the engine stopped and the starting system disabled. When servicing the generator, make sure that switch gear and automatic transfer switches will not present a shock hazard. Lock them out on the generator being serviced.Record Keeping

Maintain a log or record keeping system to document all gauge readings, problems, repairs, and maintenance performed on the equipment.Space Heaters

Moisture is a natural enemy of generators and all electrical equipment. Every effort must be made to keep the generator as dry as possible. Space heaters should be operated inside the generator when it is not in use to maintain the integrity of the generator windings.