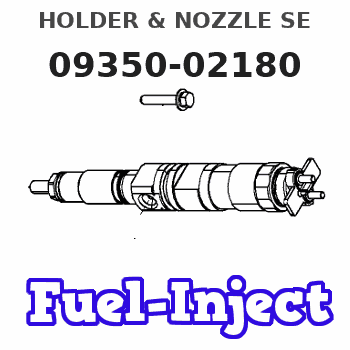

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-02180 |

| 001. | HOLDER & NOZZLE SE | 09350-02180 |

Scheme ###:

| 000. | [01] | 09350-02180 | HOLDER & NOZZLE SE | 23610-1281 |

| 000. | [01] | 09350-02180 | HOLDER & NOZZLE SE | S2361-01281 |

| 001. | [01] | 09310-02180 | HOLDER ASSY, NOZZL | S2363-01221-C |

| 001-001. | [01] | 09311-02180 | BODY SUB-ASSY, NOZ | 23602-1180 |

| 001-002. | [01] | 09312-10330 | PIN, NOZZLE HOLDER | S2361-61030-A |

| 001-003. | [01] | 09312-70280 | SPRING, NOZZLE HOL | S2361-51190-A |

| 001-004. | [01] | 09313-10210 | SCREW, ADJUST | 23614-1040 |

| 001-004. | [01] | 09313-10200 | SCREW, ADJUST | S2361-41060-A |

| 001-005. | [01] | 09313-40330 | NUT, CAP | 23623-1110 |

| 001-006. | [01] | 09315-10290 | CONNECTOR, NOZZLE | S2360-11130-A |

| 001-007. | [01] | 09315-80010 | GASKET, INLET CONN | S2362-11070-A |

| 001-008. | [01] | 09316-40940 | NUT, NOZZLE RETAIN | S2363-31190-A |

| 001-009. | [01] | 94918-00630 | SCREW, HOLLOW | S2283-51130-A |

| 001-009. | [01] | 09507-40012 | SCREW, HOLLOW OUTL | S2283-51570-A |

| 001-010. | [01] | 09324-50052 | WASHER | S2284-71290-A |

| 001-011. | [02] | 94901-02640 | WASHER | S2284-71870-A |

| 002. | [01] | 09340-01170 | NOZZLE ASSY | S2365-01360-A |

Include in #3:

09350-02180

as HOLDER & NOZZLE SE

09350-02180

Include as Nozzle:

0920000460

as Nozzle

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-02180 | 23610-1281 | HOLDER & NOZZLE SE | |

| 23610-1281 | HINO | HOLDER & NOZZLE SE | |

| S2361-01281 | HINO | HOLDER & NOZZLE SE |

Information:

Maintenance Recommendations

Caterpillar Truck Engines are certified by the United States Environmental Protection Agency to comply with smoke emission standard limits prescribed by Federal laws at the time of manufacture.Efficiency of emission control and good engine performance depend on adherence to proper operation and maintenance recommendations, use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be entrusted to your authorized dealer.Various chemical fuel additives are commercially available that claim to reduce visible smoke. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require the certification of engines without a smoke depressant.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the user that the use of such parts will not adversely affect emission levels.Regular service intervals along with special emphasis on the following items are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Lubrication and Maintenance Section of this Operation Guide for details and maintenance schedule. If the engine is operating under severe conditions, adjust maintenance schedule accordingly. See your authorized dealer to help analyze your specific maintenance schedule.The following explanation of required emission related component maintenance has been keyed by number to correspond with item number in the maintenance chart.1. COOLANT - LEVEL AND PROTECTION: Check the engine coolant level daily with the engine stopped and cool. Release cooling system pressure before checking. Fill to proper level with permanent-type antifreeze and water as free as possible from scale forming minerals. DO NOT USE SOFTENED WATER.2. CRANKCASE LUBRICATING OIL LEVEL: Check oil level before starting engine and when refueling. Check with the engine stopped. Add oil of proper classification and grade as to starting temperatures.3. CRANKCASE LUBRICATING OIL: Change oil according to Lubrication and Maintenance Chart. After filling to proper level start engine and check for leaks.4. CRANKCASE LUBRICATING OIL FILTER: Change filters at each oil change period. Check for leaks after engine is started.5. AIR CLEANER: Excessive engine exhaust smoke or loss of power may indicate the need for servicing. Never service the air cleaner while the engine is running. Service as recommended in Lubrication and Maintenance Chart or at the interval recommended by the truck manufacturer. Inspect air inlet and exhaust piping for damage which may cause restriction or leaks.6. CRANKCASE BREATHER: Remove breather element and wash with clean solvent every 30,000 miles. Inspect gaskets and replace if necessary.7. GOVERNOR: Check the engine high and low idle RPM at the first oil change and every 50,000 miles or 1,000 service hours thereafter. The engines were tested for certification at the specified speeds and should be operated within these limits. It is recommended these adjustments be made by an authorized dealer.8. AIR-FUEL RATIO CONTROL: The air-fuel ratio

Caterpillar Truck Engines are certified by the United States Environmental Protection Agency to comply with smoke emission standard limits prescribed by Federal laws at the time of manufacture.Efficiency of emission control and good engine performance depend on adherence to proper operation and maintenance recommendations, use of recommended fuels and lubricating oils. It is recommended that major adjustments and repair be entrusted to your authorized dealer.Various chemical fuel additives are commercially available that claim to reduce visible smoke. Although additives have been used by individuals to solve some isolated smoke problems in the field, they are not recommended for general use. Federal smoke regulations require the certification of engines without a smoke depressant.The corrective steps taken immediately on discovery of worn parts, which may affect emission levels, will help assure proper operation of emission control systems. The use of genuine Caterpillar parts is recommended. Suppliers of non-Caterpillar parts must assure the user that the use of such parts will not adversely affect emission levels.Regular service intervals along with special emphasis on the following items are necessary to keep exhaust emissions within acceptable limits for the useful life of the engine. Refer to the Lubrication and Maintenance Section of this Operation Guide for details and maintenance schedule. If the engine is operating under severe conditions, adjust maintenance schedule accordingly. See your authorized dealer to help analyze your specific maintenance schedule.The following explanation of required emission related component maintenance has been keyed by number to correspond with item number in the maintenance chart.1. COOLANT - LEVEL AND PROTECTION: Check the engine coolant level daily with the engine stopped and cool. Release cooling system pressure before checking. Fill to proper level with permanent-type antifreeze and water as free as possible from scale forming minerals. DO NOT USE SOFTENED WATER.2. CRANKCASE LUBRICATING OIL LEVEL: Check oil level before starting engine and when refueling. Check with the engine stopped. Add oil of proper classification and grade as to starting temperatures.3. CRANKCASE LUBRICATING OIL: Change oil according to Lubrication and Maintenance Chart. After filling to proper level start engine and check for leaks.4. CRANKCASE LUBRICATING OIL FILTER: Change filters at each oil change period. Check for leaks after engine is started.5. AIR CLEANER: Excessive engine exhaust smoke or loss of power may indicate the need for servicing. Never service the air cleaner while the engine is running. Service as recommended in Lubrication and Maintenance Chart or at the interval recommended by the truck manufacturer. Inspect air inlet and exhaust piping for damage which may cause restriction or leaks.6. CRANKCASE BREATHER: Remove breather element and wash with clean solvent every 30,000 miles. Inspect gaskets and replace if necessary.7. GOVERNOR: Check the engine high and low idle RPM at the first oil change and every 50,000 miles or 1,000 service hours thereafter. The engines were tested for certification at the specified speeds and should be operated within these limits. It is recommended these adjustments be made by an authorized dealer.8. AIR-FUEL RATIO CONTROL: The air-fuel ratio