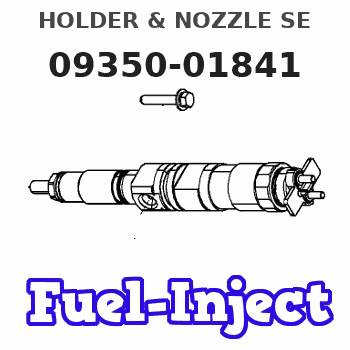

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-01841 |

Scheme ###:

| 000. | [01] | 09350-01841 | HOLDER & NOZZLE SE | |

| 001. | [01] | 09310-01841 | HOLDER ASSY, NOZZL | |

| 001-001. | [01] | 09311-01841 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10350 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70290 | SPRING, NOZZLE HOL | |

| 001-004. | [01] | 09316-20112 | SCREW, CYLINDER | |

| 001-005. | [01] | 09316-40870 | NUT, NOZZLE RETAIN | |

| 001-006. | [1C] | 09317-51560 | WASHER | |

| 001-006. | [1C] | 09317-51550 | WASHER | |

| 001-006. | [1C] | 09317-51540 | WASHER | |

| 001-006. | [1C] | 09317-51530 | WASHER | |

| 001-006. | [1C] | 09317-51520 | WASHER | |

| 001-006. | [1C] | 09317-51510 | WASHER | |

| 001-006. | [1C] | 09317-51570 | WASHER | |

| 001-006. | [1C] | 09317-51580 | WASHER | |

| 001-006. | [1C] | 09317-51590 | WASHER | |

| 001-006. | [1C] | 09317-51600 | WASHER | |

| 001-006. | [1C] | 09317-51610 | WASHER | |

| 001-006. | [1C] | 09317-51620 | WASHER | |

| 001-006. | [1C] | 09317-51630 | WASHER | |

| 001-006. | [1C] | 09317-51640 | WASHER | |

| 001-006. | [1C] | 09317-51650 | WASHER | |

| 001-006. | [1C] | 09317-51500 | WASHER | |

| 001-006. | [1C] | 09317-51180 | WASHER | |

| 001-006. | [1C] | 09317-51170 | WASHER | |

| 001-006. | [1C] | 09317-51020 | WASHER | |

| 001-006. | [1C] | 09317-51030 | WASHER | |

| 001-006. | [1C] | 09317-51040 | WASHER | |

| 001-006. | [1C] | 09317-51050 | WASHER | |

| 001-006. | [1C] | 09317-51060 | WASHER | |

| 001-006. | [1C] | 09317-51070 | WASHER | |

| 001-006. | [1C] | 09317-51080 | WASHER | |

| 001-006. | [1C] | 09317-51090 | WASHER | |

| 001-006. | [1C] | 09317-51100 | WASHER | |

| 001-006. | [1C] | 09317-51160 | WASHER | |

| 001-006. | [1C] | 09317-51150 | WASHER | |

| 001-006. | [1C] | 09317-51140 | WASHER | |

| 001-006. | [1C] | 09317-51130 | WASHER | |

| 001-006. | [1C] | 09317-51120 | WASHER | |

| 001-006. | [1C] | 09317-51110 | WASHER | |

| 001-007. | [01] | 09322-00050 | PACKING SUB-ASSY, | |

| 001-011. | [01] | 90801-10190 | O-RING | |

| 002. | [01] | 09340-00740 | NOZZLE ASSY |

Include in #3:

09350-01841

as HOLDER & NOZZLE SE

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-01841 | HOLDER & NOZZLE SE |

Information:

Start By:a. remove governor **See Disassemble Governor story

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove the bolts and the plate from the side of the fuel injection pump housing. 2. Install tool (A) in the fuel injection pump housing. Move the rack until tool (A) can be installed to hold the rack in the center position to remove the fuel injection pumps.3. Use tool (B) to remove bushing (1).4. Remove the O-ring seal from the fuel injection pump housing. 5. Install tool (C) on the bonnet and remove the fuel injection pump. 6. Remove spacer (2). Keep the spacers (2) from the fuel injection pumps together with identification as to their location in the pump housing.7. Perform steps 3 through 6 to remove the other fuel injection pumps. The following steps are to install the fuel injection pumps.8. Install spacer (2).9. Install tool (A). Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.10. Turn camshaft until the lobe of the camshaft is down for the pump to be installed.11. Install tool (C) on the bonnet on the fuel injection pump.12. Install the fuel injection pump in the pump housing with saw cut slot in the gear in alignment with the small pin and groove in the barrel in alignment with dowel in the pump housing.13. Put clean oil on O-ring seal and install it in the fuel injection pump housing.14. Install the bushing by hand until the bushing is even with the top of the housing. If the bushing can not be installed this far by hand, remove it. Remove the fuel injection pump ad put the pump in alignment again and install the bushing again.15. Install tool (B) on the bushing and tighten the bushing to a torque of 190 14 N m (140 10 lb ft).16. Install tooling (D) to measure total rack travel. Correct rack travel is 15.7 mm (.618 in). A smaller measurement is an indication of improper fuel injection pump installation.17. Perform Steps 1 through 9 to install the other fuel pumps18. Install the cover and gasket on the fuel injection pump housing.End By:a. install governor **See Assemble Governor storyDisassemble And Assemble Fuel Injection Pumps

Start By:a. remove fuel injection pumps

When the injection pumps are disassembled, handle the parts carefully. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not intermix the plunger of one pump in the barrel with another pump. If one part is worn, install a complete new pump assembly. Be careful when placing the plunger into the bore of the barrel.

1. Pull plunger (1) and washer (5) out of barrel (3) and spring (2).

Do not remove the gear from

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Remove the bolts and the plate from the side of the fuel injection pump housing. 2. Install tool (A) in the fuel injection pump housing. Move the rack until tool (A) can be installed to hold the rack in the center position to remove the fuel injection pumps.3. Use tool (B) to remove bushing (1).4. Remove the O-ring seal from the fuel injection pump housing. 5. Install tool (C) on the bonnet and remove the fuel injection pump. 6. Remove spacer (2). Keep the spacers (2) from the fuel injection pumps together with identification as to their location in the pump housing.7. Perform steps 3 through 6 to remove the other fuel injection pumps. The following steps are to install the fuel injection pumps.8. Install spacer (2).9. Install tool (A). Move the rack until tool (A) can be installed to hold the rack in the center position. The rack must be in the center position to install the fuel injection pumps.10. Turn camshaft until the lobe of the camshaft is down for the pump to be installed.11. Install tool (C) on the bonnet on the fuel injection pump.12. Install the fuel injection pump in the pump housing with saw cut slot in the gear in alignment with the small pin and groove in the barrel in alignment with dowel in the pump housing.13. Put clean oil on O-ring seal and install it in the fuel injection pump housing.14. Install the bushing by hand until the bushing is even with the top of the housing. If the bushing can not be installed this far by hand, remove it. Remove the fuel injection pump ad put the pump in alignment again and install the bushing again.15. Install tool (B) on the bushing and tighten the bushing to a torque of 190 14 N m (140 10 lb ft).16. Install tooling (D) to measure total rack travel. Correct rack travel is 15.7 mm (.618 in). A smaller measurement is an indication of improper fuel injection pump installation.17. Perform Steps 1 through 9 to install the other fuel pumps18. Install the cover and gasket on the fuel injection pump housing.End By:a. install governor **See Assemble Governor storyDisassemble And Assemble Fuel Injection Pumps

Start By:a. remove fuel injection pumps

When the injection pumps are disassembled, handle the parts carefully. Do not damage the surfaces of the plungers, barrels and bonnets. Any scratches will cause leakage inside the fuel injection pump. The plunger and barrel for each pump are made as a set. Do not intermix the plunger of one pump in the barrel with another pump. If one part is worn, install a complete new pump assembly. Be careful when placing the plunger into the bore of the barrel.

1. Pull plunger (1) and washer (5) out of barrel (3) and spring (2).

Do not remove the gear from