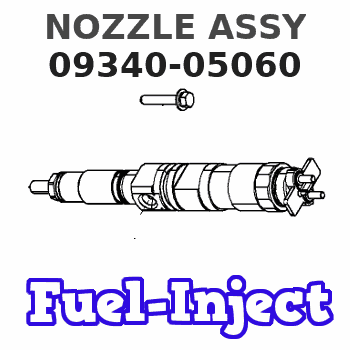

Information nozzle assy

ZEXEL

105007-1000

Nozzle Type:

ND-DN15PD6

MITSUBISHI INDUSTRIAL L2,L3

MITSUBISHI INDUSTRIAL L3

MITSUBISHI INDUSTRIAL L3C-61TG

MITSUBISHI SPACE WAGON/EXPO 4D65

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

12PCS XDEP Factory Price PND Type Fuel Injector Nozzle 093400-5060 Part No.DN15PD6

XDEP Part NO.:DN15PD6 || Application: Diesel Fuel Injection System, PDN Nozzle Replace for Injector || Guarantee: 6 Months Warranty.100% Tested Before Shipping to Ensure Product Safety,Stability and Durability || Function: High-Quality Material for Long-Lasting Durability. Perfect Match for the Injector and Easy to Install || ips: Please be Sure to Compare Carefully with Photos and Check Part Number before Buying Items, If You are not Sure This Part is Suitable, Please Feel Free to Contact Us, We'll Reply You as Soon as Possible.

XDEP Part NO.:DN15PD6 || Application: Diesel Fuel Injection System, PDN Nozzle Replace for Injector || Guarantee: 6 Months Warranty.100% Tested Before Shipping to Ensure Product Safety,Stability and Durability || Function: High-Quality Material for Long-Lasting Durability. Perfect Match for the Injector and Easy to Install || ips: Please be Sure to Compare Carefully with Photos and Check Part Number before Buying Items, If You are not Sure This Part is Suitable, Please Feel Free to Contact Us, We'll Reply You as Soon as Possible.

shsiyayh 6X Fuel Injector for DooSan SOLAR 015PLUS/S018-VT Excavator 093400-5060 0934005060

shsiyayh Part Name:Fuel Injector || Part Number:093400-5060 0934005060 || APPlication: Compatible with DooSan SOLAR 015PLUS/S018-VT Excavator Mitsubishi Engine L3E S4L-31 S6S for Mitsubishi Diesel Engine S6S L3E S3L S4L S3L2 S4L2 S4S S4L-31 L2C L2E L3C L3E2 S4Q2 || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh Part Name:Fuel Injector || Part Number:093400-5060 0934005060 || APPlication: Compatible with DooSan SOLAR 015PLUS/S018-VT Excavator Mitsubishi Engine L3E S4L-31 S6S for Mitsubishi Diesel Engine S6S L3E S3L S4L S3L2 S4L2 S4S S4L-31 L2C L2E L3C L3E2 S4Q2 || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

Fuel injector 093400-5060 DN15PD6 MD603660 Compatible for 4D65 engine

BHYZPSKO It can reduce the wear of the engine during cold start and improve the service life of the engine. || Precise control of fuel injection to ensure the normal operation of the engine under different working conditions. || The fuel is atomized into finer oil droplets to facilitate ignition and combustion, thereby improving combustion efficiency. || Optimize the formation of combustible mixture to increase engine power output. || Fuel injector 093400-5060 DN15PD6 MD603660 Compatible for 4D65 engine

BHYZPSKO It can reduce the wear of the engine during cold start and improve the service life of the engine. || Precise control of fuel injection to ensure the normal operation of the engine under different working conditions. || The fuel is atomized into finer oil droplets to facilitate ignition and combustion, thereby improving combustion efficiency. || Optimize the formation of combustible mixture to increase engine power output. || Fuel injector 093400-5060 DN15PD6 MD603660 Compatible for 4D65 engine

You can express buy:

USD 41.06

14-06-2025

14-06-2025

For Mitsubishi L2E L3E S3L S4L MM43594101 6pcs Injector Nozzle 093400-5060 DN15PD6

Images:

USD 10.49

[06-Jun-2025]

USD 2.08

[13-May-2025]

USD 36

[13-May-2025]

USD 150

[13-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09340-05060 | MD603660 | NOZZLE ASSY | |

| MD603660 | MITSUBISHI | NOZZLE ASSY |

Information:

Cooling System (Extended Life Coolant Only)

Do not perform this maintenance until you read and understand the material in the Safety and Cooling System Specifications sections of this publication.

Drain/Flush/Replace Coolant

Caterpillar Extended Life Coolant should be replaced every 6,000 Service Hours or 4 Years, whichever comes first. Only clean water is needed to clean and flush the cooling system when ELC is drained and replaced.Drain

1. Stop the engine and allow the engine to cool. Loosen the coolant filler cap slowly to relieve any pressure, and remove the cap.2. Remove the cooling system drain plug(s) or open the drain valve. Remove the drain plug from the bottom of the water pump housing (if equipped) and/or radiator. Allow the coolant to drain.

Dispose of used engine coolant properly or recycle. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant. Contact your Caterpillar dealer for information regarding disposal and recycling of used coolant.

Contact Caterpillar Service Technology Group:Outside Illinois: 1-800-542-TOOLInside Illinois: 1-800-541-TOOLCanada: 1-800-523-TOOLFlush

4. Flush the cooling system with clean water to remove any debris.5. Clean and install all drain plugs and/or close the drain valve(s).6. Fill the cooling system with clean water. Install the filler cap. Operate the engine until warm 49 to 66°C (150 to 120°F).7. Stop the engine and allow the engine to cool. Loosen the coolant filler cap slowly to relieve any pressure, and remove the cap. Remove the cooling system drain plug(s) or open the drain valve. Allow the water to drain. Flush the cooling system with clean water.8. Repeat steps 6 and 7.Fill

9. Fill the cooling system with ELC. Refer to the refill capacities chart in this manual for the amount of ELC needed to refill your system.10. Start and run the engine with the filler cap removed. Allow the ELC to warm, the thermostat to open, and the coolant level to stabilize. Add ELC if necessary to bring the coolant to the proper level.11. Check the condition of the filler cap gasket. If the gasket is damaged, discard the old filler cap and install a new filler cap. If the gasket is not damaged, use a 9S8140 Service Tool (available from your Caterpillar dealer) to pressure test the filler cap. The correct filler cap pressure is stamped on the face of the filler cap. If the filler cap does not hold the correct pressure, install a new filler cap.12. Start the engine and inspect for coolant leaks and proper operating temperature. Stop the engine.

Do not perform this maintenance until you read and understand the material in the Safety and Cooling System Specifications sections of this publication.

Drain/Flush/Replace Coolant

Caterpillar Extended Life Coolant should be replaced every 6,000 Service Hours or 4 Years, whichever comes first. Only clean water is needed to clean and flush the cooling system when ELC is drained and replaced.Drain

1. Stop the engine and allow the engine to cool. Loosen the coolant filler cap slowly to relieve any pressure, and remove the cap.2. Remove the cooling system drain plug(s) or open the drain valve. Remove the drain plug from the bottom of the water pump housing (if equipped) and/or radiator. Allow the coolant to drain.

Dispose of used engine coolant properly or recycle. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant. Contact your Caterpillar dealer for information regarding disposal and recycling of used coolant.

Contact Caterpillar Service Technology Group:Outside Illinois: 1-800-542-TOOLInside Illinois: 1-800-541-TOOLCanada: 1-800-523-TOOLFlush

4. Flush the cooling system with clean water to remove any debris.5. Clean and install all drain plugs and/or close the drain valve(s).6. Fill the cooling system with clean water. Install the filler cap. Operate the engine until warm 49 to 66°C (150 to 120°F).7. Stop the engine and allow the engine to cool. Loosen the coolant filler cap slowly to relieve any pressure, and remove the cap. Remove the cooling system drain plug(s) or open the drain valve. Allow the water to drain. Flush the cooling system with clean water.8. Repeat steps 6 and 7.Fill

9. Fill the cooling system with ELC. Refer to the refill capacities chart in this manual for the amount of ELC needed to refill your system.10. Start and run the engine with the filler cap removed. Allow the ELC to warm, the thermostat to open, and the coolant level to stabilize. Add ELC if necessary to bring the coolant to the proper level.11. Check the condition of the filler cap gasket. If the gasket is damaged, discard the old filler cap and install a new filler cap. If the gasket is not damaged, use a 9S8140 Service Tool (available from your Caterpillar dealer) to pressure test the filler cap. The correct filler cap pressure is stamped on the face of the filler cap. If the filler cap does not hold the correct pressure, install a new filler cap.12. Start the engine and inspect for coolant leaks and proper operating temperature. Stop the engine.