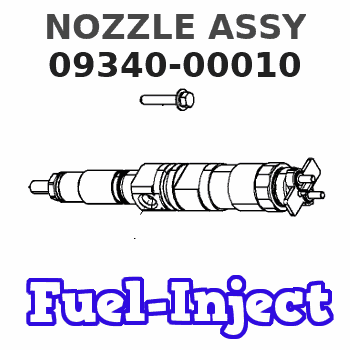

Information nozzle assy

ZEXEL

105000-1130

CAV

CAV

563065

Nozzle Type:

ND-DN4SD24

HINO HEAVY DUTY TRUCK DM100

HINO HEAVY DUTY TRUCK EC100

HINO TRUCK DM100

KOMATSU INDUSTRIAL 2D94

MITSUBISHI CANTER 4DR,6DR

MITSUBISHI INDUSTRIAL 2DQ

MITSUBISHI INDUSTRIAL 6DS,6DB

MITSUBISHI INDUSTRIAL AD100

MITSUBISHI INDUSTRIAL K30

MITSUBISHI INDUSTRIAL K4A

MITSUBISHI INDUSTRIAL K4E31HMA

MITSUBISHI INDUSTRIAL KE5

MITSUBISHI INDUSTRIAL KE55

MITSUBISHI INDUSTRIAL KE70

MITSUBISHI TRACTOR KE150T

TOYOTA BUS A/C 2J

TOYOTA DYNA 2J

TOYOTA DYNA H

TOYOTA DYNA J

TOYOTA FORK LIFT 2D

TOYOTA FORK LIFT D

TOYOTA FORK LIFT D,2D

TOYOTA INDUSTRIAL 43E

TOYOTA LAND CRUISER B

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$12.38

10 Sep 2024

0.08[0.04] pounds

Amazon.com

Hacus - Forklift FPE247072 Nozzle Assembly 2J Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

You can express buy:

USD 45.2

14-06-2025

14-06-2025

For Komatsu 4D95L Engine Forklift DN4SD24 093400-0010 0434250014 DN4SD24ND80 6x Fuel Injector Nozzle

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09340-00010 | NOZZLE ASSY | ||

| 61421-13120 | KOMATSU | NOZZLE ASSY | |

| 23650-1080 | HINO | NOZZLE ASSY | |

| 2362A-76010 | HINO | NOZZLE ASSY | |

| 23620-76010-000 | DAIHATSU | NOZZLE ASSY | |

| 23620-76010 | TOYOTA | NOZZLE ASSY | |

| ME020996 | MITSUBISHI | NOZZLE ASSY | |

| ME020996 | MITSUBISHI | NOZZLE ASSY |

Information:

1. Remove suction bell (3) and tubes, oil supply tube (2) and BrakeSaver oil supply tube (1) from the engine block and oil pump. 2. Remove three bolts (5) and oil pump (4) from the engine. The following steps are for installation of the oil pump.3. Put oil pump (4) in position on the engine. Make sure the oil pump gear is engaged with the crankshaft gear and install three bolts (5) that hold the oil pump.4. Put clean oil on the O-ring seals on the oil tubes.5. Install suction bell (3) and tubes, oil supply tube (2) and BrakeSaver oil supply tube (1).end by:a) install oil pan (BrakeSaver)Disassemble Oil Pump (Brakesaver)

start by:a) remove oil pump (BrakeSaver) 1. Remove the bolt and washer that hold drive gear (1) on the shaft.2. Use tooling (A) to remove drive gear (1) from the shaft. Remove the key from the shaft. Put marks on the pump bodies so they can be assembled in the correct position. 3. Remove retainer (3) for the bypass valve. Remove the spring and bypass valve.4. Remove bolts (4) that hold pump body (2) to the main pump body. Remove pump body (2).5. Use tooling (B) to remove the bearings from pump body (2). 6. Remove gears (7). Put marks on the gears so they can be assembled in the same position.7. Remove spacer (6) from main oil pump body (5). Use tooling (B) to remove the bearings from spacer (6).8. Remove the gears from main oil pump body (5). 9. Use tooling (B) to remove the bearings from the main oil pump body.Assemble Oil Pump (Brakesaver)

1. Use tooling (A) to install bearings (2) until they are even with the outside surface of main oil pump body (1). Install bearings (2) so the junctions in the bearings are 30° 15° from the center line of the bearing bores and toward the oil pump outlet passage as shown. 2. Use tooling (A) to install bearings (3) in the spacer. Install the bearings until they are in position an equal distance in from each side of the spacer. Install the bearings with the oil holes in the bearings in alignment with the oil holes in the spacer and the junctions in the bearings in alignment with the cavity in the spacer as shown. 3. Put clean engine oil on all the gears and bearings before they are assembled in the oil pump. Install idler and drive gears (5) in the main oil pump body.4. Install spacer (4) on the gear shafts with the smaller cavity out and the oil holes in the spacer toward the pump outlet passage as shown. 5. Use tooling (A) to install bearings (6) in pump body (7) until they are .060 .010 in. (1.52 0.25 mm) from the inside edge of the bearing bores. Install the bearings so the junctions in the bearings are 30° 15° from the center line of the bearing bores and toward the outlet passage. The

start by:a) remove oil pump (BrakeSaver) 1. Remove the bolt and washer that hold drive gear (1) on the shaft.2. Use tooling (A) to remove drive gear (1) from the shaft. Remove the key from the shaft. Put marks on the pump bodies so they can be assembled in the correct position. 3. Remove retainer (3) for the bypass valve. Remove the spring and bypass valve.4. Remove bolts (4) that hold pump body (2) to the main pump body. Remove pump body (2).5. Use tooling (B) to remove the bearings from pump body (2). 6. Remove gears (7). Put marks on the gears so they can be assembled in the same position.7. Remove spacer (6) from main oil pump body (5). Use tooling (B) to remove the bearings from spacer (6).8. Remove the gears from main oil pump body (5). 9. Use tooling (B) to remove the bearings from the main oil pump body.Assemble Oil Pump (Brakesaver)

1. Use tooling (A) to install bearings (2) until they are even with the outside surface of main oil pump body (1). Install bearings (2) so the junctions in the bearings are 30° 15° from the center line of the bearing bores and toward the oil pump outlet passage as shown. 2. Use tooling (A) to install bearings (3) in the spacer. Install the bearings until they are in position an equal distance in from each side of the spacer. Install the bearings with the oil holes in the bearings in alignment with the oil holes in the spacer and the junctions in the bearings in alignment with the cavity in the spacer as shown. 3. Put clean engine oil on all the gears and bearings before they are assembled in the oil pump. Install idler and drive gears (5) in the main oil pump body.4. Install spacer (4) on the gear shafts with the smaller cavity out and the oil holes in the spacer toward the pump outlet passage as shown. 5. Use tooling (A) to install bearings (6) in pump body (7) until they are .060 .010 in. (1.52 0.25 mm) from the inside edge of the bearing bores. Install the bearings so the junctions in the bearings are 30° 15° from the center line of the bearing bores and toward the outlet passage. The