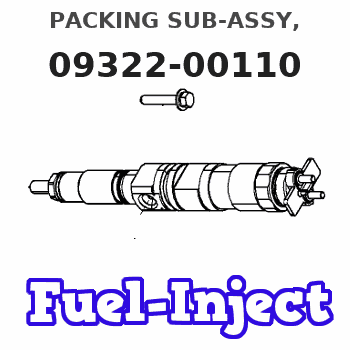

Information packing sub-assy,

Rating:

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09322-00110 | PACKING SUB-ASSY, |

Information:

The engine cranks but the engine does not start.

Check the engine fuel system.

Crank the engine.

Observe the action of the fuel rack and the governor.

If a 2301A Electric Governor is installed, measure the voltage that is supplied to the governor.Result

The fuel rack and the governor move into the FUEL ON direction.The problem is in the engine or in the fuel system. Refer to the engine Service Manual. STOP.

The fuel rack does not move. The governor does not move in the FUEL ON direction.The start/stop switch was not in the START position. Go to Step 2.

A 2301A Electric Governor is installed and the supply voltage is greater than 15 volts.The problem is in the governor or the actuator system. Refer to the 2301A Electric Governor Service Manual, SENR3585. STOP.

A 2301A Electric Governor is installed and the supply voltage is less than 15 volts.The problem is in the wiring to the 2301A Electric Governor. Go to Step 3.

Check the slave relay (SR1) and the fuel rack.

Disconnect the wire from terminal (TS-30) to the fuel shutoff solenoid (FSOS). The wire is on the terminal strip in the junction box.

Crank the engine. Stop the engine with the emergency stop switch if trouble occurs.

Reconnect the wire when the test is completed.Result

The engine starts and the engine runs.The slave relay (SR1) is energizing the shutoff solenoid. Go to Step 3.

The engine does not start.The shutoff solenoid is stuck or the fuel rack is stuck in the shutoff position. Find the source of the problem and correct the source of the problem. STOP.

Check the slave relay (SR1).

Disconnect the wire that connects terminal (SR1-85) of the slave relay (SR1) to terminal (TD-7) of the time delay relay. Insulate the end of the removed wire in order to prevent contact with any conductive surfaces.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.

Reconnect the wire when the test is completed.Result

The engine starts and the engine runs.The (SR1) is not faulty. Go to Step 4.

The engine does not start.Contacts (SR1-30) and (SR1-87) of (SR1) that are normally open have been shorted and the fuel shutoff solenoid is energized. If a 2301A Electric Governor is installed, contacts (SR-30) and (SR-87a) of (SR1) that are normally closed are open or the wiring to the 2301A Electric Governor is faulty. Replace the (SR1) or repair the wiring problem. Refer to Testing and Adjusting, "Slave Relay Test". STOP.

Check the protection switches and the time delay relay (TD).

Disconnect the jumper between the terminals (TS-9) and (TS-10) of the junction box.

If the engine is equipped with a low oil pressure indicator, disconnect the diode that is between terminals (TS-8) and (TS-10). The cathode lead of the diode should be connected to terminal (TS-10).

Ensure that a jumper is not installed between terminals (TS-8) and (TS-9).

Crank the engine.Result

The engine starts and the engine runs.The problem is in the switches for the oil pressure (OPS1) or in the water temperature contactor switch (WTS). Go to Step 5.

The engine does not start.The problem is not

Check the engine fuel system.

Crank the engine.

Observe the action of the fuel rack and the governor.

If a 2301A Electric Governor is installed, measure the voltage that is supplied to the governor.Result

The fuel rack and the governor move into the FUEL ON direction.The problem is in the engine or in the fuel system. Refer to the engine Service Manual. STOP.

The fuel rack does not move. The governor does not move in the FUEL ON direction.The start/stop switch was not in the START position. Go to Step 2.

A 2301A Electric Governor is installed and the supply voltage is greater than 15 volts.The problem is in the governor or the actuator system. Refer to the 2301A Electric Governor Service Manual, SENR3585. STOP.

A 2301A Electric Governor is installed and the supply voltage is less than 15 volts.The problem is in the wiring to the 2301A Electric Governor. Go to Step 3.

Check the slave relay (SR1) and the fuel rack.

Disconnect the wire from terminal (TS-30) to the fuel shutoff solenoid (FSOS). The wire is on the terminal strip in the junction box.

Crank the engine. Stop the engine with the emergency stop switch if trouble occurs.

Reconnect the wire when the test is completed.Result

The engine starts and the engine runs.The slave relay (SR1) is energizing the shutoff solenoid. Go to Step 3.

The engine does not start.The shutoff solenoid is stuck or the fuel rack is stuck in the shutoff position. Find the source of the problem and correct the source of the problem. STOP.

Check the slave relay (SR1).

Disconnect the wire that connects terminal (SR1-85) of the slave relay (SR1) to terminal (TD-7) of the time delay relay. Insulate the end of the removed wire in order to prevent contact with any conductive surfaces.

Crank the engine. Stop the engine with the emergency stop switch, if trouble occurs.

Reconnect the wire when the test is completed.Result

The engine starts and the engine runs.The (SR1) is not faulty. Go to Step 4.

The engine does not start.Contacts (SR1-30) and (SR1-87) of (SR1) that are normally open have been shorted and the fuel shutoff solenoid is energized. If a 2301A Electric Governor is installed, contacts (SR-30) and (SR-87a) of (SR1) that are normally closed are open or the wiring to the 2301A Electric Governor is faulty. Replace the (SR1) or repair the wiring problem. Refer to Testing and Adjusting, "Slave Relay Test". STOP.

Check the protection switches and the time delay relay (TD).

Disconnect the jumper between the terminals (TS-9) and (TS-10) of the junction box.

If the engine is equipped with a low oil pressure indicator, disconnect the diode that is between terminals (TS-8) and (TS-10). The cathode lead of the diode should be connected to terminal (TS-10).

Ensure that a jumper is not installed between terminals (TS-8) and (TS-9).

Crank the engine.Result

The engine starts and the engine runs.The problem is in the switches for the oil pressure (OPS1) or in the water temperature contactor switch (WTS). Go to Step 5.

The engine does not start.The problem is not