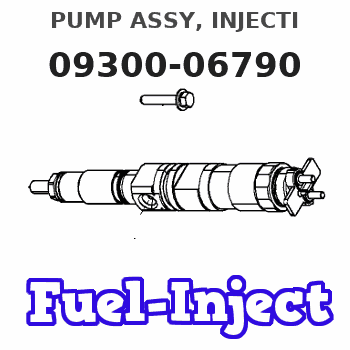

Information pump assy, injecti

Nozzle:

0935007500

Rating:

KIT List:

| Governor assy, mec | 1908900720 |

| Timer assy, automa | No Application |

| Pump assy, fuel fe | 1922900060 |

| Body assy, injecti | 1904400380 |

Components :

| 001. | PUMP ASSY, INJECTI | 09300-06790 |

| 002. | GOVERNOR ASSY, MEC | 09130-07520 |

| 003. | LEVER SET | 09129-10860 |

| 004. | COMPENSATOR SUB-AS | 19260-01330 |

| 005. | TIMER ASSY, AUTOMA | 09180-03754 |

| 006. | PUMP ASSY, FUEL FE | 09210-02840 |

| 007. | BODY ASSY, INJECTI | 19010-00962 |

Scheme ###:

| 000. | [01] | 09300-06790 | PUMP ASSY, INJECTI | ME225375 |

| 003. | [01] | 19010-00962 | BODY ASSY, INJECTI | ME736900 |

| 004. | [01] | 09130-07520 | GOVERNOR ASSY, MEC | ME743913 |

| 005. | [01] | 09180-03754 | TIMER ASSY, AUTOMA | ME736904 |

| 006. | [01] | 09210-02840 | PUMP ASSY, FUEL FE | ME736506 |

| 007. | [01] | 09006-00570 | COVER SUB-ASSY, TI | ME743445 |

| 008. | [01] | 94914-03690 | O-RING | ME736557 |

| 009. | [01] | 90458-05750 | KEY, WOODRUFF | ME702920 |

| 010. | [01] | 09001-20360 | NUT, TIMER ROUND | ME736909 |

| 011. | [01] | 94901-81550 | WASHER, COPPER PLA | ME039681 |

| 012. | [01] | 09001-80410 | COVER, CONTROL RAC | ME736558 |

| 013. | [01] | 09028-50021 | CAP | ME035845 |

| 014. | [04] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 015. | [04] | 90258-10001 | WASHER, SPRING | MC327716 |

| 016. | [04] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 017. | [02] | 94904-76880 | BOLT, W/WASHER | ME728977 |

| 018. | [01] | 94904-76910 | BOLT, W/WASHER | ME728980 |

| 019. | [01] | 94904-76900 | BOLT, W/WASHER | ME728979 |

| 020. | [04] | 94904-76890 | BOLT, W/WASHER | ME728978 |

| 023. | [01] | 09028-50050 | CAP | ME076458 |

Include in #3:

09300-06790

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09300-06790 | ME225375 | PUMP ASSY, INJECTI | |

| ME225375 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Diesel Particulate Filters (DPF) are not applicable to all engines. A Diesel Particulate Filter should typically not be applied to engines that are not regulated. Diesel Particulate Filters are meant for usage on only diesel engines. This technology does not apply to gas engines. Consult with Caterpillar in order to determine if a Diesel Particulate Filter can be used on your engine.

Included in this guide is a parts list and installation procedure. Each section is highlighted for your convenience.Read each section carefully prior to installing your DPF.Consult your Caterpillar dealer with questions concerning installation or warranty-related matters.Note: Ultra-Low sulfur Diesel fuel must be used. Ultra Low Sulfur Diesel (ULSD) fuel (≤ 15 ppm (mg/kg) sulfur) is required by regulation for diesel engine use in California. The United States (U.S.) Environmental Protection Agency (EPA) defines Ultra Low Sulfur Diesel (ULSD - S15) as a U.S. diesel fuel with a sulfur content not to exceed 15 parts per million (ppm (mg/kg)). Also, the sulfur content in the diesel fuel is not to exceed 0.0015 percent by weight. ULSD fuel must meet the S-15 fuels designation in the latest edition of ASTM D975 and/or conform to Caterpillar Fuel Specification.Warranty and Record Of Installation

The statement of warranty for the DPF can be found at the end of this installation manual.Be sure to record the information from the DPF housing label prior to installation.System Parts

One (1) Caterpillar DPF with data monitoring The DPF system consists of the following components:

(1) Catalyst Section

(1) Filter Section

(1) Inlet Head

(1) Outlet Head

(3) V-Band clamps

(3) Gaskets

(1) DPF Diagnostic Module to monitor the backpressure and temperature of your DPF. Refer to the DPF Diagnostic Module (DPFdm) manual for installation and operating instructions.

(1) DPF Diagnostic Module installation kit, including thermocouple, pressure sampling tube and wiring harness

(1) Remote Display Module (RDM).

One (1) packet consisting of:

Engine Label

Record Of Installation

Installation Guide

Bill of Materials

Depending on your DPF purchase, additional auxiliary items may be included such as brackets, piping and insulation. Check your bill of materials for a complete listing. System Installation Procedure

Note: Reference Special Instruction, REHS5606 for complete system installation information.

Inspect engine to ensure that it meets engine manufacturers specifications or correct the engine to meet the engine manufacturers specifications. Note: Caterpillar requires prior to installation of a DPF, each engine must be inspected by a mechanic to determine that the engine meets all of the engine manufacturers specifications. Failure to meet the correct engine specifications could void the DPF warranty. Check your warranty for details.

Remove the outlet pipe from the existing muffler.

Remove the inlet pipe from the existing muffler.

Remove the existing mounting brackets/bands.

Remove the existing muffler.

If the existing clamps and brackets are to be reused, inspect clamps and brackets to ensure that they are not fatigued or cracked. Replace these components as required.

The DPF system is shipped as a ready to install assembly, however, the t-bolt and lock-nut on