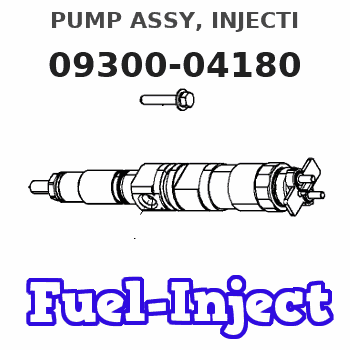

Information pump assy, injecti

Nozzle:

0935003820

Rating:

KIT List:

| Body assy, injecti | 1904400320 |

| Pump assy, fuel fe | 1922900060 |

| Governor assy, mec | 1908900170 |

Components :

| 001. | PUMP ASSY, INJECTI | 09300-04180 |

| 002. | BODY ASSY, INJECTI | 09010-09800 |

| 003. | PUMP ASSY, FUEL FE | 09210-01540 |

| 004. | GOVERNOR ASSY, MEC | 19080-03020 |

Scheme ###:

| 000. | [01] | 09300-04180 | PUMP ASSY, INJECTI | ME080588 |

| 006. | [01] | 09010-09800 | BODY ASSY, INJECTI | ME728935 |

| 007. | [01] | 19080-03020 | GOVERNOR ASSY, MEC | ME728241 |

| 008. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 009. | [01] | 94913-00210 | KEY, WOODRUFF | ME702047 |

| 010. | [01] | 09210-01540 | PUMP ASSY, FUEL FE | ME703397 |

| 011. | [01] | 09001-20220 | NUT, TIMER ROUND | ME702033 |

| 012. | [01] | 91518-08221 | BOLT, W/WASHER | MM500963 |

| 013. | [06] | 91418-06161 | BOLT, W/WASHER | ME702149 |

| 014. | [01] | 09001-80090 | COVER, CONTROL RAC | ME702251 |

| 015. | [01] | 09006-00320 | COVER SUB-ASSY, TI | ME703649 |

| 016. | [04] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 017. | [04] | 90258-10001 | WASHER, SPRING | MC327716 |

| 018. | [04] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 019. | [01] | 94914-02840 | O-RING | MH035502 |

| 020. | [01] | 09185-10330 | GEAR, TIMER DRIVIN | ME728032 |

| 021. | [01] | 09255-10412 | BLOCK, COUPLING | ME017724 |

| 022. | [04] | 90258-08001 | WASHER, SPRING | MB239626 |

| 023. | [04] | 94904-04471 | BOLT, HEXAGON | ME702248 |

Include in #3:

09300-04180

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09300-04180 | ME080588 | PUMP ASSY, INJECTI | |

| ME080588 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Table 1

Diagnostic Trouble Codes

J1939 Code and Description CDL Code and Description

4334–20

Aftertreatment #1 DEF #1 Pressure (absolute) : Data Drifted High 3090–20

Aftertreatment #1 DEF Pressure Sensor : Data Drifted High

4334-21

Aftertreatment #1 DEF #1 Pressure (absolute) : Data Drifted Low 3090-21

Aftertreatment #1 DEF Pressure Sensor : Data Drifted Low

3361-5

Aftertreatment #1 DEF Dosing Unit : Current Below Normal 3821-5

Aftertreatment #1 Diesel Exhaust Fluid Dosing Valve Actuator : Current Below Normal

3361-6

Aftertreatment #1 DEF Dosing Unit : Current Above Normal 3821-6

Aftertreatment #1 Diesel Exhaust Fluid Dosing Valve Actuator : Current Above Normal

3516-12

Aftertreatment #1 DEF Concentration : Failure 3100-12

Aftertreatment #1 DEF Tank Fluid Quality Sensor : Failure

Table 2

Event Codes

J1939 Code and Description CDL Code and Description

5392-31

Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime E1370 (2)

Aftertreatment #1 DEF Dosing Unit Loss of Prime

4334-18

Aftertreatment #1 DEF #1 Pressure (absolute) : Low - moderate severity (2) E931 (2)

Low Aftertreatment #1 DEF Pressure

4334-16

Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2) E930 (2)

High Aftertreatment #1 DEF Pressure

3516-16

Aftertreatment #1 DEF Concentration : High - moderate severity (2) E1365 (2)

High Aftertreatment #1 DEF Concentration

3516-18

Aftertreatment #1 DEF Concentration : Low - moderate severity (2) E1364 (2)

Low Aftertreatment #1 DEF Concentration

5246-15

Aftertreatment SCR Operator Inducement Severity : High - least severe (1) E1389 (1)

Aftertreatment #1 SCR Operator Inducement

5246-16

Aftertreatment SCR Operator Inducement Severity : High - moderate severity (2) E1389 (2)

Aftertreatment #1 SCR Operator Inducement

5246-0

Aftertreatment SCR Operator Inducement Severity : High - most severe (3) E1389 (3)

Aftertreatment #1 SCR Operator Inducement Ensure that DEF fluid conforms to specification ISO 22241 requirements and fluid handling, filling, and storage procedures are strictly followed.All transfer equipment and storage containers should be used exclusively for DEF and should not be reused for other fluids. For example coolants, fuels, oils, and windshield washer fluid.If contamination of the DEF system is suspected, refer to Troubleshooting, DEF Concentration is Incorrect. Ensure that the correct troubleshooting steps are followed. To test for contamination of the DEF tank, refer to Systems Operation Testing and Adjusting, Diesel Exhaust Fluid Quality - Test.If the DEF is contaminated, Caterpillar recommends that the DEF tank is flushed. Refer to Systems Operation Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush for the correct procedure.