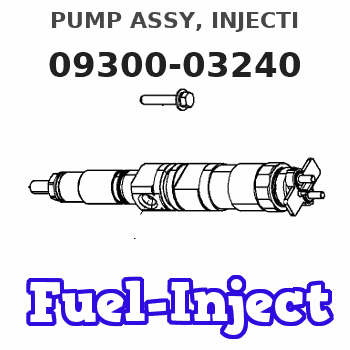

Information pump assy, injecti

Nozzle:

0935004470

Rating:

KIT List:

| Body assy, injecti | 1904400300 |

| Timer assy, automa | 0918030050 |

| Pump assy, fuel fe | 1922900060 |

| Pump assy, fuel fe | 1922900060 |

| Governor assy, mec | 1908900250 |

Components :

| 001. | PUMP ASSY, INJECTI | 09300-03240 |

| 002. | BODY ASSY, INJECTI | 09010-08670 |

| 003. | TIMER ASSY, AUTOMA | 09180-02800 |

| 003. | TIMER ASSY, AUTOMA | 09180-02800 |

| 003. | TIMER ASSY, AUTOMA | 09180-02800 |

| 004. | PUMP ASSY, FUEL FE | 09210-01140 |

| 005. | PUMP ASSY, FUEL FE | 09210-01551 |

| 006. | GOVERNOR ASSY, MEC | 19080-02620 |

| 006. | GOVERNOR ASSY, MEC | 19080-02620 |

Scheme ###:

| 000. | [01] | 09300-03240 | PUMP ASSY, INJECTI | ME001593 |

| 003. | [01] | 09010-08670 | BODY ASSY, INJECTI | ME728124 |

| 004. | [01] | 19080-02620 | GOVERNOR ASSY, MEC | ME728126 |

| 005. | [01] | 09210-01140 | PUMP ASSY, FUEL FE | ME016021 |

| 005. | [01] | 09210-01551 | PUMP ASSY, FUEL FE | ME703037 |

| 006. | [01] | 09180-02800 | TIMER ASSY, AUTOMA | ME728123 |

| 006. | [01] | 09180-02801 | TIMER ASSY, AUTOMA | ME728123 |

| 006. | [01] | 09180-02802 | TIMER ASSY, AUTOMA | ME728123 |

| 007. | [01] | 09006-00140 | COVER SUB-ASSY, TI | ME006130 |

| 008. | [01] | 94914-03990 | O-RING | MH035501 |

| 009. | [04] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 010. | [04] | 90258-10001 | WASHER, SPRING | MC327716 |

| 011. | [04] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 012. | [01] | 94913-00190 | KEY, WOODRUFF | ME703361 |

| 013. | [01] | 94901-50500 | WASHER, SPRING | ME008373 |

| 014. | [01] | 09001-20260 | NUT, TIMER ROUND | ME703450 |

| 015. | [01] | 09001-80081 | COVER, CONTROL RAC | ME702034 |

| 016. | [06] | 94904-70620 | BOLT, W/WASHER | ME703359 |

| 019. | [02] | 09028-50021 | CAP | ME035845 |

Include in #3:

09300-03240

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09300-03240 | ME001593 | PUMP ASSY, INJECTI | |

| ME001593 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Stop Engine At Once If Any Part Fails

Almost all failures give a warning to the operator before the part completely fails. If the operator is alert and heeds the warnings, further damage may not happen. A few of the warning signs are: abnormal gauge readings, abnormal fluid levels, fluid leaks, unusual engine noises and excessive smoke. Do not operate an engine if any sign of part failure is present, only a few seconds can ruin an entire engine.Start vehicle in motion by utilizing the lowest gear speed in the transmission that will enable the engine to easily start the load without slipping the clutch. Accelerate smoothly and evenly until the engine speed reaches approximately 100% of rated RPM. Rapid depression of accelerator will result in undesirable heavy exhaust smoke and high fuel consumption with no increase in vehicle performance. Upshift to the next higher gear speed. If properly done, the engine speed will be above approximately 80% of rated RPM when the load is applied. For best performance do not skip gears. Engine speed should not be permitted to drop appreciably below 80% of rated RPM, to avoid a lugging condition.Caterpillar engines have good lugging characteristics; however, operating in a lug condition for extended periods of time should be avoided as it causes exhaust temperatures to rise and also results in high fuel consumption. A lug condition exists when an increase in engine speed cannot be achieved with an increase in accelerator pedal position, or when engine speed decreases with the accelerator pedal in its maximum position. A lug condition can exist at any engine speed below full load speed. Continue to make successive upshifts through each gear speed in the transmission until cruising speed is reached. In each gear speed, accelerate smoothly to an engine speed of approximately 100% of rated RPM before upshifting to the next gear. For highway cruising, maintain the engine speed between approximately 80% and 100% of rated RPM. Operating in this range will give maximum fuel economy.When going up a grade and the engine speed drops to below approximately 80% of rated RPM, downshift successively until a gear speed is reached that will enable the engine to pull the load without operating in a lug condition. When pulling a long grade, such as encountered in mountain driving, make additional downshifts of one or two gears immediately prior to reaching the summit. This will allow the engine to cool more slowly than if the load on the engine is suddenly changed from a full load condition going uphill to no load condition going downhill. Prevent overspeeding of the engine when going down long, steep grades. Downshift to a gear speed that will permit a desired vehicle speed with an engine speed not in excess of high idle RPM. This will usually be the same gear speed that would be used to go up that grade.Periodic braking of the vehicle may be required to help slow the engine speed on steep slopes.Engine Shut-Down

Before stopping

Almost all failures give a warning to the operator before the part completely fails. If the operator is alert and heeds the warnings, further damage may not happen. A few of the warning signs are: abnormal gauge readings, abnormal fluid levels, fluid leaks, unusual engine noises and excessive smoke. Do not operate an engine if any sign of part failure is present, only a few seconds can ruin an entire engine.Start vehicle in motion by utilizing the lowest gear speed in the transmission that will enable the engine to easily start the load without slipping the clutch. Accelerate smoothly and evenly until the engine speed reaches approximately 100% of rated RPM. Rapid depression of accelerator will result in undesirable heavy exhaust smoke and high fuel consumption with no increase in vehicle performance. Upshift to the next higher gear speed. If properly done, the engine speed will be above approximately 80% of rated RPM when the load is applied. For best performance do not skip gears. Engine speed should not be permitted to drop appreciably below 80% of rated RPM, to avoid a lugging condition.Caterpillar engines have good lugging characteristics; however, operating in a lug condition for extended periods of time should be avoided as it causes exhaust temperatures to rise and also results in high fuel consumption. A lug condition exists when an increase in engine speed cannot be achieved with an increase in accelerator pedal position, or when engine speed decreases with the accelerator pedal in its maximum position. A lug condition can exist at any engine speed below full load speed. Continue to make successive upshifts through each gear speed in the transmission until cruising speed is reached. In each gear speed, accelerate smoothly to an engine speed of approximately 100% of rated RPM before upshifting to the next gear. For highway cruising, maintain the engine speed between approximately 80% and 100% of rated RPM. Operating in this range will give maximum fuel economy.When going up a grade and the engine speed drops to below approximately 80% of rated RPM, downshift successively until a gear speed is reached that will enable the engine to pull the load without operating in a lug condition. When pulling a long grade, such as encountered in mountain driving, make additional downshifts of one or two gears immediately prior to reaching the summit. This will allow the engine to cool more slowly than if the load on the engine is suddenly changed from a full load condition going uphill to no load condition going downhill. Prevent overspeeding of the engine when going down long, steep grades. Downshift to a gear speed that will permit a desired vehicle speed with an engine speed not in excess of high idle RPM. This will usually be the same gear speed that would be used to go up that grade.Periodic braking of the vehicle may be required to help slow the engine speed on steep slopes.Engine Shut-Down

Before stopping