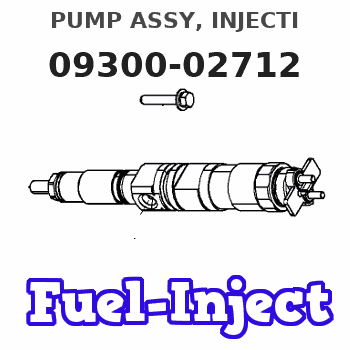

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09300-02712 |

| 002. | BODY ASSY, INJECTI | 09010-08240 |

| 003. | TIMER ASSY, AUTOMA | 09180-02310 |

| 004. | PUMP ASSY, FUEL FE | 09210-01510 |

Scheme ###:

| 000. | [01] | 09300-02712 | PUMP ASSY, INJECTI | 22010-5130 |

| 004. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80090 | COVER, CONTROL RAC | 22114-1250A |

| 007. | [04] | 94904-72690 | BOLT, W/WASHER | 22815-2410A |

| 008. | [01] | 94904-74850 | BOLT, W/WASHER | 22815-2900A |

| 009. | [01] | 09006-00150 | COVER SUB-ASSY, TI | 22825-1470A |

| 010. | [01] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 012. | [01] | 09130-00932 | GOVERNOR ASSY, MEC | 22310-3980A |

| 013. | [01] | 09210-01510 | PUMP ASSY, FUEL FE | 22570-1240A |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 015. | [01] | 09180-02310 | TIMER ASSY, AUTOMA | 22510-1910A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 018. | [01] | 09010-08240 | BODY ASSY, INJECTI | 22110-2420A |

| 021. | [04] | 91266-10081 | NUT, HEXAGON | 22825-1490A |

| 022. | [04] | 90258-10001 | WASHER, SPRING | 28219-1120A |

| 023. | [04] | 94901-15020 | WASHER, STEEL PLAT | 22877-1551A |

Include in #3:

09300-02712

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09300-02712 | 22010-5130 | PUMP ASSY, INJECTI |

Information:

Introduction

There are three approved processes for performing the required Diesel Particulate Filter (DPF) maintenance on Tier 4 Final products equipped with a DPF.Do not perform any procedure in this Special Instruction until you have read this entire Special Instruction and you understand this information. Caterpillar does not recommend any equipment or process for cleaning the DPF other than the procedures listed in this Special Instruction.Note: The approved Caterpillar DPF maintenance procedure permits any of the following actions be taken when the DPF needs to be cleaned:

Replacement of the existing DPF with a new Caterpillar DPF

Replacement of the existing DPF with a remanufactured Caterpillar DPF

Replacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device.The DPF can be cleaned a maximum of 3 times or 20,000 total DPF hours.Replacement with a New or a Remanufactured Caterpillar Diesel Particulate Filter (DPF)

Refer to Table 1 for the existing part number of the filter assembly being serviced along with the corresponding new and remanufactured service kits.

Table 1

DPF Part Number Service Kit Part Number Part Number of Included Clamp Reman Service Kit part Number

390-0659 390-0679 375-0949 N/A

390-0643 390-0645 371-1871 N/A

375-0945 375-0946 375-0949 N/A

371-1855 371-1856 371-1871 N/A

371-1896 371-1897 375-0931 N/A

390-0663 390-0665 345-1839/375-0931 N/A

390-0673 390-0675 375-0931 N/A

375-0992 375-0993 345-1839/375-0931 N/A Refer to Reman Core Acceptance Criteria, SELD0292 for further information.When replacing the existing DPF with either a new or remanufactured DPF, perform the following:

Mark the DPF as shown below in Step 4

Perform a "Manual DPF Regeneration"

Perform the "DPF Ash Service" listed belowReplacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device

Inorder tomaintain emissions documentation, it is necessary that only the same part number DPF must be reinstalled. The cleaned DPF must have a remaining service life similar to the DPF being replaced.Inspect the DPF for markings of a previous cleaning. Refer to Illustration 1 for a typical example of cleaning markings.Cleaning the DPF

Follow this cleaning procedure for removal of the ash from a DPF. Refer to the Operation and Maintenance Manual for the intervals of service hours for cleaning of the DPF.Note: Identify all engine fault codes if black soot is discovered on the outlet side of the center section on the DPF. Reference the engine Troubleshooting Manual for problem identification and the disposition of the DPF.

Refer to Special Instruction, REHS5704, "Testing the Diesel Particulate Filter (DPF) for Cracks and Leaks" to perform the crack detection test. Proceed to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test.

Connect to the "Engine # 1 Aftertreatment Controller" using Cat ET before the DPF is removed. Perform a "DPF Ash Service Regeneration". The service test could take up to an hour. Note: Allow the DPF to cool until the DPF can be safely removed.

Remove the DPF from the Clean Emissions Module (CEM).

Illustration 1 g03530378

Typical example of marking the DPF.

Mark the DPF after removing from the CEM. The process for marking includes a code that will identify the

There are three approved processes for performing the required Diesel Particulate Filter (DPF) maintenance on Tier 4 Final products equipped with a DPF.Do not perform any procedure in this Special Instruction until you have read this entire Special Instruction and you understand this information. Caterpillar does not recommend any equipment or process for cleaning the DPF other than the procedures listed in this Special Instruction.Note: The approved Caterpillar DPF maintenance procedure permits any of the following actions be taken when the DPF needs to be cleaned:

Replacement of the existing DPF with a new Caterpillar DPF

Replacement of the existing DPF with a remanufactured Caterpillar DPF

Replacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device.The DPF can be cleaned a maximum of 3 times or 20,000 total DPF hours.Replacement with a New or a Remanufactured Caterpillar Diesel Particulate Filter (DPF)

Refer to Table 1 for the existing part number of the filter assembly being serviced along with the corresponding new and remanufactured service kits.

Table 1

DPF Part Number Service Kit Part Number Part Number of Included Clamp Reman Service Kit part Number

390-0659 390-0679 375-0949 N/A

390-0643 390-0645 371-1871 N/A

375-0945 375-0946 375-0949 N/A

371-1855 371-1856 371-1871 N/A

371-1896 371-1897 375-0931 N/A

390-0663 390-0665 345-1839/375-0931 N/A

390-0673 390-0675 375-0931 N/A

375-0992 375-0993 345-1839/375-0931 N/A Refer to Reman Core Acceptance Criteria, SELD0292 for further information.When replacing the existing DPF with either a new or remanufactured DPF, perform the following:

Mark the DPF as shown below in Step 4

Perform a "Manual DPF Regeneration"

Perform the "DPF Ash Service" listed belowReplacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device

Inorder tomaintain emissions documentation, it is necessary that only the same part number DPF must be reinstalled. The cleaned DPF must have a remaining service life similar to the DPF being replaced.Inspect the DPF for markings of a previous cleaning. Refer to Illustration 1 for a typical example of cleaning markings.Cleaning the DPF

Follow this cleaning procedure for removal of the ash from a DPF. Refer to the Operation and Maintenance Manual for the intervals of service hours for cleaning of the DPF.Note: Identify all engine fault codes if black soot is discovered on the outlet side of the center section on the DPF. Reference the engine Troubleshooting Manual for problem identification and the disposition of the DPF.

Refer to Special Instruction, REHS5704, "Testing the Diesel Particulate Filter (DPF) for Cracks and Leaks" to perform the crack detection test. Proceed to Step 2 if the DPF passes the crack detection test. Contact the Technical Communicator, if the DPF fails the test.

Connect to the "Engine # 1 Aftertreatment Controller" using Cat ET before the DPF is removed. Perform a "DPF Ash Service Regeneration". The service test could take up to an hour. Note: Allow the DPF to cool until the DPF can be safely removed.

Remove the DPF from the Clean Emissions Module (CEM).

Illustration 1 g03530378

Typical example of marking the DPF.

Mark the DPF after removing from the CEM. The process for marking includes a code that will identify the