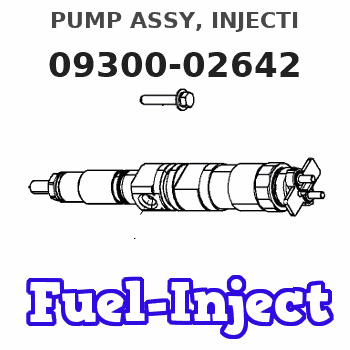

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09300-02642 |

| 002. | BODY ASSY, INJECTI | 09010-08240 |

| 003. | GOVERNOR ASSY, MEC | 09130-00953 |

| 004. | COVER ASSY, GOVERN | 09145-00360 |

| 005. | TIMER ASSY, AUTOMA | 09180-01700 |

| 006. | PUMP ASSY, FUEL FE | 09210-01510 |

Scheme ###:

| 000. | [01] | 09300-02642 | PUMP ASSY, INJECTI | 22010-5050 |

| 004. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80090 | COVER, CONTROL RAC | 22114-1250A |

| 007. | [04] | 94904-72690 | BOLT, W/WASHER | 22815-2410A |

| 008. | [01] | 94904-74850 | BOLT, W/WASHER | 22815-2900A |

| 009. | [01] | 09006-00150 | COVER SUB-ASSY, TI | 22825-1470A |

| 010. | [01] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 012. | [01] | 09130-00953 | GOVERNOR ASSY, MEC | |

| 013. | [01] | 09210-01510 | PUMP ASSY, FUEL FE | 22570-1240A |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 015. | [01] | 09180-01700 | TIMER ASSY, AUTOMA | 22510-1560A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 018. | [01] | 09010-08240 | BODY ASSY, INJECTI | 22110-2420A |

| 021. | [04] | 91266-10081 | NUT, HEXAGON | 22825-1490A |

| 022. | [04] | 90258-10001 | WASHER, SPRING | 28219-1120A |

| 023. | [04] | 94901-15020 | WASHER, STEEL PLAT | 22877-1551A |

Include in #3:

09300-02642

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09300-02642 | 22010-5050 | PUMP ASSY, INJECTI |

Information:

Introduction

This Special Instruction has been written in order to provide procedural information for testing capsule type fuel nozzles.There is an extensive amount of information that relates to the setup and the calibration of the tools that will be used to test the fuel nozzles.Additionally, there is information on the setup and operation of the cleaning equipment that is necessary in order to properly clean the fuel nozzles.There is also a publication that provides record sheets. These record sheets can be used for recording and correlating the test data that is accumulated. The following information will summarize the related documentation.

For information on the setup, operation, and the calibration of the test equipment, refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle Testing Group".

For information that relates to the setup and operation of the tools that are used to clean fuel nozzles, refer to Special Instruction, SEHS8627, "Using the 8S-2245 Nozzle Cleaning Tool Group".

Use the Special Instruction, SEHS8144, "Engine Nozzle Test Record" in order to record the results while you are testing each fuel nozzle. These record sheets are available through normal channels for literature distribution. The record sheets are available in pads that contain 50 sheets.Note: The publications that are mentioned above may contain information that must be referenced in order to test the fuel injection nozzles.Testing Capsule Type Fuel Nozzles

Ensure that you wear eye protection at all times during testing. When fuel injection nozzles are tested, test fluids travel through the orifices of the nozzle tip with high pressure. Under this amount of pressure, the test fluid can pierce the skin and cause serious injury to the operator. Always keep the tip of the fuel injection nozzle pointed away from the operator and into the fuel collector and extension.

Always ensure that the test fixture is in proper working order. Check that the fluid reservoir contains clean test fluid. Failure to do so may damage the fuel nozzles that you are testing and will reduce the life of the test equipment.

Note: Prior to starting this test procedure, the 5P-4150 Nozzle Testing Group must be equipped with a 8T-0860 Pressure Gauge . Replace the original 8T-0859 Pressure Gauge with the 8T-0860 Pressure Gauge . Refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle Testing Group" for information that relates to the replacement of the pressure gauge.Visual Inspection of the Fuel Nozzle

Perform a visual inspection of the fuel nozzle. Inspect each fuel nozzle for any sign of damage that may contribute to the improper operation of the fuel nozzle. Check for signs of damage that may have been caused by any of the following conditions:

Engine overheating (discolored fuel nozzles)

Improper cleaning (use of a wire brush for cleaning)

Fuel nozzles that are deformed or bent

Cracking or splitting of the nozzle tip

Damage to the fuel nozzle's inlet screen

Other obvious damageNote: If there are signs of engine overheating, all of the fuel nozzles must be replaced. If any of these forms of damage has been found, do not use the damaged

This Special Instruction has been written in order to provide procedural information for testing capsule type fuel nozzles.There is an extensive amount of information that relates to the setup and the calibration of the tools that will be used to test the fuel nozzles.Additionally, there is information on the setup and operation of the cleaning equipment that is necessary in order to properly clean the fuel nozzles.There is also a publication that provides record sheets. These record sheets can be used for recording and correlating the test data that is accumulated. The following information will summarize the related documentation.

For information on the setup, operation, and the calibration of the test equipment, refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle Testing Group".

For information that relates to the setup and operation of the tools that are used to clean fuel nozzles, refer to Special Instruction, SEHS8627, "Using the 8S-2245 Nozzle Cleaning Tool Group".

Use the Special Instruction, SEHS8144, "Engine Nozzle Test Record" in order to record the results while you are testing each fuel nozzle. These record sheets are available through normal channels for literature distribution. The record sheets are available in pads that contain 50 sheets.Note: The publications that are mentioned above may contain information that must be referenced in order to test the fuel injection nozzles.Testing Capsule Type Fuel Nozzles

Ensure that you wear eye protection at all times during testing. When fuel injection nozzles are tested, test fluids travel through the orifices of the nozzle tip with high pressure. Under this amount of pressure, the test fluid can pierce the skin and cause serious injury to the operator. Always keep the tip of the fuel injection nozzle pointed away from the operator and into the fuel collector and extension.

Always ensure that the test fixture is in proper working order. Check that the fluid reservoir contains clean test fluid. Failure to do so may damage the fuel nozzles that you are testing and will reduce the life of the test equipment.

Note: Prior to starting this test procedure, the 5P-4150 Nozzle Testing Group must be equipped with a 8T-0860 Pressure Gauge . Replace the original 8T-0859 Pressure Gauge with the 8T-0860 Pressure Gauge . Refer to Tool Operating Manual, SEHS7292, "Using the 5P-4150 Nozzle Testing Group" for information that relates to the replacement of the pressure gauge.Visual Inspection of the Fuel Nozzle

Perform a visual inspection of the fuel nozzle. Inspect each fuel nozzle for any sign of damage that may contribute to the improper operation of the fuel nozzle. Check for signs of damage that may have been caused by any of the following conditions:

Engine overheating (discolored fuel nozzles)

Improper cleaning (use of a wire brush for cleaning)

Fuel nozzles that are deformed or bent

Cracking or splitting of the nozzle tip

Damage to the fuel nozzle's inlet screen

Other obvious damageNote: If there are signs of engine overheating, all of the fuel nozzles must be replaced. If any of these forms of damage has been found, do not use the damaged