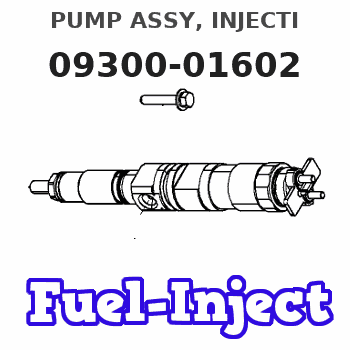

Information pump assy, injecti

Rating:

Components :

| 001. | PUMP ASSY, INJECTI | 09300-01602 |

| 002. | BODY ASSY, INJECTI | 09010-05303 |

| 003. | GOVERNOR ASSY, MEC | 09130-00971 |

| 004. | COVER ASSY, GOVERN | 09145-00881 |

| 005. | TIMER ASSY, AUTOMA | 09180-02310 |

| 006. | PUMP ASSY, FUEL FE | 09210-01510 |

Scheme ###:

| 000. | [01] | 09300-01602 | PUMP ASSY, INJECTI | 22010-4700 |

| 004. | [01] | 09031-00130 | VALVE ASSY, OVERFL | 22107-1090A |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80401 | COVER, CONTROL RAC | 22114-1160A |

| 007. | [04] | 94904-72690 | BOLT, W/WASHER | 22815-2410A |

| 008. | [01] | 94904-74850 | BOLT, W/WASHER | 22815-2900A |

| 009. | [01] | 09006-00150 | COVER SUB-ASSY, TI | 22825-1470A |

| 010. | [01] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22511-1060A |

| 015. | [01] | 09180-02310 | TIMER ASSY, AUTOMA | 22510-1910A |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 018. | [01] | 09010-05303 | BODY ASSY, INJECTI | 22110-1790A |

| 019. | [03] | 90258-06001 | WASHER, SPRING | 28219-1110A |

| 020. | [03] | 90160-06051 | NUT, HEXAGON | 22825-1480A |

| 021. | [01] | 09210-01510 | PUMP ASSY, FUEL FE | 22570-1240A |

| 023. | [01] | 09130-00971 | GOVERNOR ASSY, MEC | |

| 027. | [04] | 91266-10081 | NUT, HEXAGON | 22825-1490A |

| 028. | [04] | 90258-10001 | WASHER, SPRING | 28219-1120A |

| 029. | [04] | 94901-15020 | WASHER, STEEL PLAT | 22877-1551A |

| 030. | [01] | 90170-06361 | NUT, HEXAGON | 92100-6040A |

| 031. | [01] | 09003-10070 | SCREW, CONTROL RAC | 22396-1210A |

| 032. | [02] | 09045-90030 | PIN | 22358-1010A |

Include in #3:

09300-01602

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09300-01602 | 22010-4700 | PUMP ASSY, INJECTI |

Information:

Introduction

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.ReferenceSpecial Instruction, REHS0116, "Removal and Installation of the Hydraulic Electronic Unit Injectors"Improvements have been made to the Hydraulic Electronic Unit Injectors used in 3408E and 3412E machine engine applications. This Special Instruction includes the necessary information in order to convert the fuel system. A conversion involves the replacement of the set of injectors. Also, a software update is needed for this conversion. The new software for the injectors will work with either versions of the Electronic Control Module (ECM), the old 172-0802 Engine Electronic Control Gp or the newer 156-7172 Engine Electronic Control Gp . An adjustment of the Full Load Setting (FLS) and the Full Torque Setting (FTS) may be necessary on some machines. See Table 1 and Table 2 for this information.Individual injectors may still be repaired or replaced. The troubleshooting tests that are listed should be used in order to determine the repair method.Note: Do not mix the former injectors with the current injectors that are found in Table 2. The appropriate software package is required for proper engine performance.Note: Verify that the software that is listed in Table 2 is available before you convert a fuel system. The original software version for the machine engines can be retrieved from the Technical Marketing Information (TMI). The TMI data is the most accurate database in order to identify the original software version of the fuel system. This latest software will be available through the Caterpillar Service Information System (SIS).Serviceable Parts

Table 1

Part Number Part Name Quantity

See Table 2. Injector 1 per cylinder

See Table 2. Software 1

116-7221 Rectangular Seal 2 per cylinder

116-7222 Rectangular Seal 1 per cylinder

9X-7681 O-Ring Seal 1 per cylinder

3E-6747 O-Ring Seal 1 per cylinder Collect Data When Injectors Are Being Replaced in Chassis

Table 2 lists the part numbers and the settings for the different machine serial numbers. The range of engine serial numbers that was built with the former injector and the former software is also provided in Table 2. The range of machine serial numbers is approximate and shown only for reference.The following instructions must be followed closely in order to ensure that accurate information is collected for the change from prime to non-prime injectors and software. The information will be used to troubleshoot the engine if there is a power issue.

The operator must monitor the oil temperature gauge for the torque converter to ensure that the temperature does not go into the red zone.

Note: Run the test before you replace the injectors. Then, run the test after you install the new injectors. This will aid in troubleshooting if a power loss is reported in the future.

Start the Data Logger in Caterpillar Electronic Technician (ET). Set the speed of collection

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.ReferenceSpecial Instruction, REHS0116, "Removal and Installation of the Hydraulic Electronic Unit Injectors"Improvements have been made to the Hydraulic Electronic Unit Injectors used in 3408E and 3412E machine engine applications. This Special Instruction includes the necessary information in order to convert the fuel system. A conversion involves the replacement of the set of injectors. Also, a software update is needed for this conversion. The new software for the injectors will work with either versions of the Electronic Control Module (ECM), the old 172-0802 Engine Electronic Control Gp or the newer 156-7172 Engine Electronic Control Gp . An adjustment of the Full Load Setting (FLS) and the Full Torque Setting (FTS) may be necessary on some machines. See Table 1 and Table 2 for this information.Individual injectors may still be repaired or replaced. The troubleshooting tests that are listed should be used in order to determine the repair method.Note: Do not mix the former injectors with the current injectors that are found in Table 2. The appropriate software package is required for proper engine performance.Note: Verify that the software that is listed in Table 2 is available before you convert a fuel system. The original software version for the machine engines can be retrieved from the Technical Marketing Information (TMI). The TMI data is the most accurate database in order to identify the original software version of the fuel system. This latest software will be available through the Caterpillar Service Information System (SIS).Serviceable Parts

Table 1

Part Number Part Name Quantity

See Table 2. Injector 1 per cylinder

See Table 2. Software 1

116-7221 Rectangular Seal 2 per cylinder

116-7222 Rectangular Seal 1 per cylinder

9X-7681 O-Ring Seal 1 per cylinder

3E-6747 O-Ring Seal 1 per cylinder Collect Data When Injectors Are Being Replaced in Chassis

Table 2 lists the part numbers and the settings for the different machine serial numbers. The range of engine serial numbers that was built with the former injector and the former software is also provided in Table 2. The range of machine serial numbers is approximate and shown only for reference.The following instructions must be followed closely in order to ensure that accurate information is collected for the change from prime to non-prime injectors and software. The information will be used to troubleshoot the engine if there is a power issue.

The operator must monitor the oil temperature gauge for the torque converter to ensure that the temperature does not go into the red zone.

Note: Run the test before you replace the injectors. Then, run the test after you install the new injectors. This will aid in troubleshooting if a power loss is reported in the future.

Start the Data Logger in Caterpillar Electronic Technician (ET). Set the speed of collection