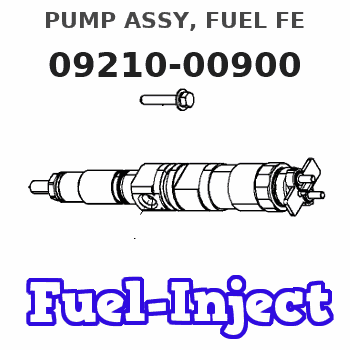

Information pump assy, fuel fe

Rating:

Scheme ###:

| 000. | [01] | 09210-00900 | PUMP ASSY, FUEL FE | |

| 003. | [01] | 09212-00240 | HOUSING SUB-ASSY, | |

| 003-001. | [01] | 09216-80150 | ROD, FEED PUMP PUS | |

| 003-001. | [1C] | 09216-80070 | ROD, FEED PUMP PUS | |

| 003-001. | [1C] | 09216-80060 | ROD, FEED PUMP PUS | |

| 003-001. | [1C] | 09216-80050 | ROD, FEED PUMP PUS | |

| 003-001. | [1C] | 09216-80040 | ROD, FEED PUMP PUS | |

| 003-001. | [1C] | 09216-80030 | ROD, FEED PUMP PUS | |

| 003-001. | [1C] | 09216-80010 | ROD, FEED PUMP PUS | |

| 003-002. | [01] | 94915-00970 | SEAL, OIL | |

| 003-002. | [01] | 94915-02700 | SEAL, OIL | |

| 005. | [02] | 09212-10011 | VALVE, FEED PUMP C | |

| 006. | [02] | 09212-40010 | SPRING, FEED PUMP | |

| 007. | [02] | 09212-50010 | GASKET, CHECK VALV | R515456 |

| 008. | [01] | 09212-60010 | PLUG, FEED PUMP CH | |

| 009. | [01] | 09213-00220 | PUMP SUB-ASSY, PRI | |

| 011. | [01] | 09217-10011 | PISTON, FEED PUMP | |

| 012. | [01] | 09217-40041 | TAPPET, FEED PUMP | |

| 013. | [01] | 09217-60021 | ROLLER, FEED PUMP | |

| 014. | [01] | 09217-80030 | PIN, FEED PUMP TAP | |

| 015. | [02] | 09217-90081 | BLOCK, FEED PUMP T | |

| 016. | [01] | 94907-20940 | RING, SNAP | |

| 017. | [01] | 09218-20020 | SPRING, FEED PUMP | |

| 018. | [01] | 09218-40021 | PLUG, FEED PUMP PI | |

| 019. | [01] | 94918-00310 | SCREW, HOLLOW | |

| 020. | [04] | 09022-20050 | WASHER, FUEL PIPE | |

| 022. | [01] | 09218-80010 | WASHER | |

| 023. | [01] | 09219-00010 | STRAINER SUB-ASSY | |

| 024. | [01] | 09220-10010 | SPRING | |

| 025. | [01] | 09220-20030 | HOUSING, STRAINER | |

| 026. | [01] | 09221-30010 | CLAMP, YOKE | |

| 027. | [01] | 09221-00010 | NUT SUB-ASSY, CLAM | |

| 028. | [01] | 09221-50010 | BOLT, STUD | |

| 030. | [01] | 94901-81240 | WASHER, COPPER PLA | |

| 031. | [02] | 09221-70060 | NIPPLE, SWIVEL |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 09210-00900 | PUMP ASSY, FUEL FE |

Information:

Engine Operating Cost Summary

The Operating Cost Summary is exactly what it implies, a summary. Here the total dollar expense and percentage of the total operating expense is calculated for each subsection. The individual elements are then totaled and divided by the ownership period to yield the cost per hour. Similar calculations are also made for only the maintenance and repair portion of the total operating cost.An Engine Operating Cost Analysis is a useful tool that can be used to: * Project the expected operating cost of a Caterpillar engine.* Identify the impact of individual elements on engine operating costs.* Determine expected operating costs if Caterpillar service and overhaul recommendations are followed.* Determine the cost per hour figures that you can obtain by having your dealer perform various levels of preventive maintenance as recommended by Caterpillar.* Determine the savings to be realized if Caterpillar repair kits, exchange components, etc., are used by those of you who elect to perform your own maintenance.* Determine the proper way to realize full value of your Caterpillar Engine by utilizing genuine Caterpillar parts and following Caterpillar recommended guidelines for preventive maintenance and before failure repairs.In conclusion, an Engine Operating Cost Analysis is a tool that was designed to identify costly problem areas for the purpose of helping you reduce your operating costs.

The Operating Cost Summary is exactly what it implies, a summary. Here the total dollar expense and percentage of the total operating expense is calculated for each subsection. The individual elements are then totaled and divided by the ownership period to yield the cost per hour. Similar calculations are also made for only the maintenance and repair portion of the total operating cost.An Engine Operating Cost Analysis is a useful tool that can be used to: * Project the expected operating cost of a Caterpillar engine.* Identify the impact of individual elements on engine operating costs.* Determine expected operating costs if Caterpillar service and overhaul recommendations are followed.* Determine the cost per hour figures that you can obtain by having your dealer perform various levels of preventive maintenance as recommended by Caterpillar.* Determine the savings to be realized if Caterpillar repair kits, exchange components, etc., are used by those of you who elect to perform your own maintenance.* Determine the proper way to realize full value of your Caterpillar Engine by utilizing genuine Caterpillar parts and following Caterpillar recommended guidelines for preventive maintenance and before failure repairs.In conclusion, an Engine Operating Cost Analysis is a tool that was designed to identify costly problem areas for the purpose of helping you reduce your operating costs.