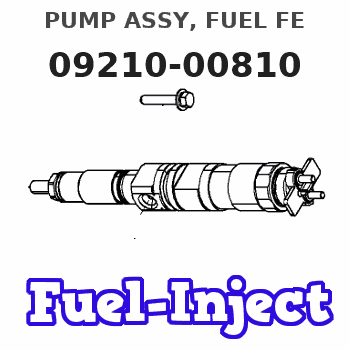

Information pump assy, fuel fe

Rating:

Scheme ###:

| 000. | [01] | 09210-00810 | PUMP ASSY, FUEL FE | 22570-1010 |

| 003. | [01] | 09212-00171 | HOUSING SUB-ASSY, | 22580-1030 |

| 003-001. | [01] | 09216-80150 | ROD, FEED PUMP PUS | 22565-1250A |

| 003-001. | [1C] | 09216-80070 | ROD, FEED PUMP PUS | 22565-1190A |

| 003-001. | [1C] | 09216-80060 | ROD, FEED PUMP PUS | 22565-1180A |

| 003-001. | [1C] | 09216-80050 | ROD, FEED PUMP PUS | 22565-1170A |

| 003-001. | [1C] | 09216-80040 | ROD, FEED PUMP PUS | 22565-1160A |

| 003-001. | [1C] | 09216-80030 | ROD, FEED PUMP PUS | 22565-1150A |

| 003-001. | [1C] | 09216-80010 | ROD, FEED PUMP PUS | 22565-1140A |

| 003-002. | [01] | 94915-00970 | SEAL, OIL | 22827-1090A |

| 003-002. | [01] | 94915-02700 | SEAL, OIL | 22827-1700A |

| 005. | [02] | 09212-10011 | VALVE, FEED PUMP C | 22563-1041A |

| 006. | [02] | 09212-40010 | SPRING, FEED PUMP | 22562-1020A |

| 007. | [02] | 09212-50010 | GASKET, CHECK VALV | 22847-1680A |

| 008. | [01] | 09212-60010 | PLUG, FEED PUMP CH | 22845-1350A |

| 009. | [01] | 09213-00050 | PUMP SUB-ASSY, PRI | 6 056 1500 50 |

| 011. | [01] | 09217-10011 | PISTON, FEED PUMP | 22566-1200A |

| 013. | [01] | 09217-60010 | ROLLER, FEED PUMP | 22569-1110A |

| 014. | [01] | 09217-80010 | PIN, FEED PUMP TAP | 22571-1100A |

| 015. | [02] | 09217-90050 | BLOCK, FEED PUMP T | 22572-1080A |

| 016. | [01] | 94907-20940 | RING, SNAP | 22887-1160A |

| 018. | [01] | 94901-81240 | WASHER, COPPER PLA | 22847-1690A |

| 019. | [01] | 09218-40021 | PLUG, FEED PUMP PI | 22845-1360A |

| 020. | [01] | 09222-30070 | SCREW, FUEL PIPE H | 22835-1370A |

| 021. | [01] | 09222-00040 | FILTER, FEED PUMP | 22574-1040A |

| 022. | [01] | 94918-00310 | SCREW, HOLLOW | S2283-51310-A |

| 023. | [04] | 94901-02490 | WASHER | 22877-1100A |

| 024. | [01] | 09217-40030 | TAPPET, FEED PUMP | 22568-1180A |

| 025. | [01] | 09218-20040 | SPRING, FEED PUMP | 22567-1110 |

Include in #3:

09000-09411

as PUMP ASSY, FUEL FE

09210-00810

Cross reference number

| Part num | Firm num | Firm | Name |

| 09210-00810 | 22570-1010 | PUMP ASSY, FUEL FE | |

| 22570-1010 | HINO | PUMP ASSY, FUEL FE |

Information:

* This photo shows the model 6D14.(Turbocharged engine)

* This photo shows the model 6D14-T.2. Major Specifications

2.1 Major Specifications

2.2 Engine Outputs Classified by Application

1. The output (SAE, gross) is corrected to standard ambient conditions based on SAE J1349.2. The continuous rated output allows 10% (one hour) overload operation.3. Engine Number And Nameplate

(1) Engine number The engine number is stamped on the position as illustrated.Example: The engine number is important in knowing the history of the engine.(2) Nameplate The nameplate is attached to the portion as illustrated.The nameplate bears the followings: 4. General Precautions For Servicing

Before starting the service procedures, check the vehicle for total time driven, use conditions, and user's complaints and requests to know exactly the engine conditions. Record information where necessary.To ensure you are doing correct and efficient service jobs, observe the following precautions: (1) Before performing the service procedures given in this manual, know the trouble spots and isolate the possible cause to determine whether the removal or disassembly procedure is required.(2) Select a flat surface for the service job.(3) When servicing the electrical system, be sure to disconnect the negative cable from the battery.(4) Carefully check parts for oil leaks before cleaning. After cleaning, it may become difficult to spot defective areas.(5) Ready and make the most of the special tools required for servicing. Use the right tools (specified special tools) in the right place to prevent damages to parts and personal injury.(6) Make alignment marks and keep disassembled parts neatly arranged to ensure that they are reassembled into the right positions.* Special care must be taken for assemblies involving a number of parts, similar parts, or parts identical at right- and left-hand sides to ensure correct reassembly.* For alignment and punching markings, select a position that would not mar the appearance and function.* Clearly distinguish parts to be replaced from those reused. (7) The oil seals, packings, O-rings, and other rubber parts, gaskets, and split pins must be replaced with a new one whenever they are removed. For replacement, use Mitsubishi Genuine parts. (8) Apply the specified grease to U-packings, oil seals, dust seals, and bearings before installation.(9) When work requires an assistant or two, always make sure of the safety each other. Never play with switches and levers.(10) Make sure that your shoes are free from grease and oil especially when working on a heavy item.(11) When checking or changing lubricants, wipe off grease and oil from parts immediately with a waste.(12) Special care must be taken in handling sensors and relays which are suspectible to shocks and heat.(13) Use care so that hands and fingers are not injured by sharp edges or corners of the parts.(14) Wear safety goggles whenever handling a grinder or welding machine. Wear gloves as required to ensure utmost safety.5. General Bolts And Nuts Tightening Torque Table

Unless otherwise specified, the parts and equipment of vehicle must be tightened by the following standard bolts and nuts. Tightening torques for these bolts and nuts are shown below. 1. Threads and