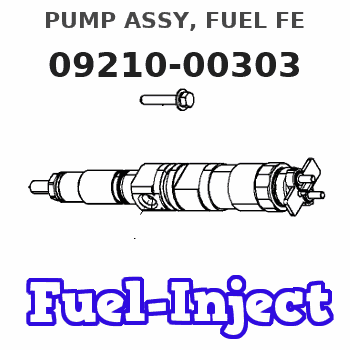

Information pump assy, fuel fe

Rating:

Scheme ###:

| 000. | [01] | 09210-00303 | PUMP ASSY, FUEL FE | |

| 001. | [01] | 09212-60010 | PLUG, FEED PUMP CH | 09212-60010 |

| 002. | [02] | 09212-50010 | GASKET, CHECK VALV | 09212-50010 |

| 003. | [02] | 09212-40010 | SPRING, FEED PUMP | 09212-40010 |

| 004. | [02] | 09212-10011 | VALVE, FEED PUMP C | 09212-10010 |

| 005. | [01] | 94918-00310 | SCREW, HOLLOW | 94918-00310 |

| 006. | [04] | 09022-20011 | WASHER, FUEL PIPE | 09022-20011 |

| 007. | [01] | 09218-40021 | PLUG, FEED PUMP PI | 09218-40020 |

| 008. | [01] | 94901-81240 | WASHER, COPPER PLA | 94901-81240 |

| 009. | [01] | 09218-20020 | SPRING, FEED PUMP | 09218-20020 |

| 010. | [01] | 09217-10011 | PISTON, FEED PUMP | 09217-10010 |

| 011. | [01] | 09212-00120 | HOUSING SUB-ASSY, | |

| 011. | [01] | 09212-00121 | HOUSING SUB-ASSY, | |

| 011-001. | [01] | 09216-80150 | ROD, FEED PUMP PUS | 09216-80150 |

| 011-001. | [1C] | 09216-80070 | ROD, FEED PUMP PUS | 09216-80070 |

| 011-001. | [1C] | 09216-80060 | ROD, FEED PUMP PUS | 09216-80060 |

| 011-001. | [1C] | 09216-80050 | ROD, FEED PUMP PUS | 09216-80050 |

| 011-001. | [1C] | 09216-80040 | ROD, FEED PUMP PUS | 09216-80040 |

| 011-001. | [1C] | 09216-80030 | ROD, FEED PUMP PUS | 09216-80030 |

| 011-001. | [1C] | 09216-80010 | ROD, FEED PUMP PUS | 09216-80010 |

| 011-002. | [01] | 94915-02700 | SEAL, OIL | |

| 013. | [01] | 09222-00040 | FILTER, FEED PUMP | 09222-00040 |

| 014. | [01] | 09222-30070 | SCREW, FUEL PIPE H | 09222-30070 |

| 016. | [01] | 09217-40030 | TAPPET, FEED PUMP | 09217-40030 |

| 017. | [02] | 09217-90050 | BLOCK, FEED PUMP T | 09217-90050 |

| 017. | [02] | 09217-90031 | BLOCK, FEED PUMP T | 09217-90030 |

| 018. | [01] | 09217-80010 | PIN, FEED PUMP TAP | 09217-80010 |

| 019. | [01] | 09217-60010 | ROLLER, FEED PUMP | 09217-60010 |

| 020. | [01] | 94907-20940 | RING, SNAP | 94907-20940 |

| 021. | [01] | 09213-00050 | PUMP SUB-ASSY, PRI | 09213-00050 |

| 021. | [01] | 09213-00200 | PUMP SUB-ASSY, PRI | |

| 021. | [01] | 09213-00220 | PUMP SUB-ASSY, PRI |

Include in #3:

09000-02303

as PUMP ASSY, FUEL FE

09210-00303

Cross reference number

| Part num | Firm num | Firm | Name |

| 09210-00303 | PUMP ASSY, FUEL FE |

Information:

Q1Description

The A.350 type exhauster, which is fitted to the 4.236 engine, is a rotary sliding vane pump, with an eccentrically mounted rotor.The exhauster body and end covers are of cast iron, and house an aluminium rotor, die-cast on to a steel shaft. The rotor has four equi-spaced slots to accommodate fibre blades.The shaft runs in a sintered bronze plain bearing in the rear end cover, and a roller race in the drive end cover, or, alternatively, two sintered bronze bearings. Drive end covers with a roller race have two shaft seals which contact a hardened steel collar pressed on to the rotor shaft. The seals are arranged to prevent ingress of air and dirt, and leakage of oil from the exhauster. Drive end covers with a plain bearing have only one seal, preventing oil leakage.The shaft drive end is splined to take the drive gear.The intake port in the exhauster is pipe connected to the vacuum reservoir. The outlet port formed in the end cover of the exhauster aligns with the aperture in the timing case.Lubrication is by engine pressure feed, oil entering through a connection in the rear end cover to an annular groove in the bearing housing. The oil passes through a hole in the bearing to oilways in the rotor shaft communicating with the slots in the rotor. The oil passes through the end of the rotor slots to lubricate the drive end roller bearing. When a plain bearing is fitted in the drive end cover, it receives oil through an extension of the main oilway in the rotor shaft.A passage in the drive end cover to the vacuum side of the pump relieves oil pressure on the seal.Operation

At all speeds the rotor blades are kept in contact with the bore of the body by centrifugal force, assisted by the hydraulic action of the oil beneath the blades. When the rotor turns, the spaces between the blades vary because of the eccentric mounting of the rotor in the exhauster body. As a blade passes the inlet port, the space between it and the following blade is increasing and air is drawn from the vacuum reservoir. This air is then compressed and expelled, with the lubricating oil, through the outlet port to the engine timing case.Periodic Inspections and Preventive Maintenance

Every 5,000 miles (7,500 km) or 250 Hours

Check the vacuum lines and fittings. (Vacuum leakage may occur through the line, or reservoir mounted non-return valve if the valve seat is dirty or pitted). Examine the exhauster for evidence of oil leakage, particularly at end cover joints, and at shaft oil seal.Check the oil supply line for leaks at fittings and connections.Check the mounting and end cover nuts and bolts for tightness.Every 60,000 Miles (90,000 km) or 2,500 Hours

Remove and dismantle exhauster, thoroughly clean all parts and inspect for wear and damage. Repair or replace the exhauster with a Factory Replacement Unit.Removal

Disconnect oil and vacuum pipes at the exhauster and plug ends to prevent the entry of foreign