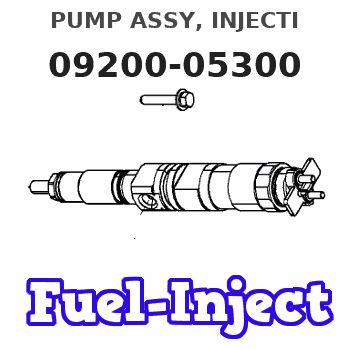

Information pump assy, injecti

Nozzle:

0935007820

Rating:

KIT List:

| Governor assy, mec | 1908900720 |

| Timer assy, automa | No Application |

| Pump assy, fuel fe | 1922900070 |

| Body assy, injecti | 1904400380 |

Components :

| 001. | PUMP ASSY, INJECTI | 09200-05300 |

| 001. | PUMP ASSY, INJECTI | 09200-05300 |

| 002. | GOVERNOR ASSY, MEC | 09130-07460 |

| 003. | LEVER SET | 09129-10331 |

| 004. | COMPENSATOR SUB-AS | 19260-01710 |

| 005. | TIMER ASSY, AUTOMA | 09180-03742 |

| 006. | PUMP ASSY, FUEL FE | 09210-03120 |

| 007. | COUPLING ASSY | 09250-01061 |

| 008. | BODY ASSY, INJECTI | 19010-01401 |

| 009. | COVER, BEARING | 09020-10430 |

Scheme ###:

| 000. | [01] | 09200-05300 | PUMP ASSY, INJECTI | 22010-9170 |

| 000. | [01] | 09200-05300 | PUMP ASSY, INJECTI | 22010-E0310 |

| 003. | [01] | 19010-01401 | BODY ASSY, INJECTI | 22110-3611A |

| 004. | [01] | 09130-07460 | GOVERNOR ASSY, MEC | |

| 005. | [01] | 09180-03742 | TIMER ASSY, AUTOMA | S2251-03060-A |

| 006. | [01] | 09001-20340 | NUT, TIMER ROUND | S2282-52240-A |

| 007. | [01] | 09250-01061 | COUPLING ASSY | S2261-01860-A |

| 008. | [01] | 90458-05750 | KEY, WOODRUFF | S2289-11070-A |

| 009. | [01] | 09210-03120 | PUMP ASSY, FUEL FE | S2257-01690-A |

| 010. | [01] | 09001-80381 | COVER, CONTROL RAC | S2211-41200-A |

| 011. | [01] | 94901-81550 | WASHER, COPPER PLA | SL722-02215 |

| 012. | [01] | 94904-76900 | BOLT, W/WASHER | S2281-53230-A |

| 013. | [04] | 94904-76890 | BOLT, W/WASHER | S2281-53210-A |

| 014. | [01] | 94904-76910 | BOLT, W/WASHER | S2281-53240-A |

| 015. | [02] | 94904-76880 | BOLT, W/WASHER | S2281-53320-A |

| 018. | [01] | 09028-50030 | CAP | S2232-31210-A |

| 019. | [01] | 09028-50050 | CAP | S2232-31430-A |

| 021. | [02] | 94901-02480 | WASHER | S2284-71940-A |

| 022. | [01] | 09031-00450 | VALVE ASSY, OVERFL | S2210-71570-A |

| 023. | [02] | 91808-08121 | BOLT, FLANGE | S2281-53330-A |

| 024. | [01] | 09069-00900 | BRACKET SUB-ASSY, | S2204-41330-A |

| 025. | [02] | 91808-08201 | BOLT, FLANGE | S2281-53390-A |

| 026. | [01] | 09045-30190 | STAY, INJECTION PU | S1140-91270-C |

| 027. | [01] | 09028-50030 | CAP | S2232-31210-A |

Include in #3:

09200-05300

as PUMP ASSY, INJECTI

09200-05300

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-05300 | 22010-9170 | PUMP ASSY, INJECTI | |

| 22010-E0310 | HINO | PUMP ASSY, INJECTI | |

| 22010-9170 | HINO | PUMP ASSY, INJECTI |

Information:

Fuel Pump Reference Parts

1. Select a pump typically serviced in your dealer shop. Do NOT use electronic (PEEC) fuel pumps as reference parts. A 3306B pump is recommended for your reference pump.2. If necessary, disassemble and visually inspect pump cam, lifters, plunger and barrel, etc. to assure all internal components are in good condition.3. Check pump plunger and barrel bonnet nut torque. Torque nuts to recommended value according to the service manual.4. Back out the pump governor load stop(s) and idle setting screws.5. Obtain the required pump rack zero pin. It is recommended each reference pump have its own zero pin (order a spare from the parts department) and permanently attach to the reference pump.6. Install the reference pump on the test stand.7. Make sure the test stand has the latest master fuel nozzles. All master nozzles must have the same part number.8. Inspect each test stand high pressure fuel line inside diameter (ID) for "close-in" from repeated use.Repeated assembly of the high pressure fuel lines can cause the tubing's inside diameter to collapse or "close-in", resulting in low delivery volume. Testing fuel injection pumps using worn or partially closed high pressure fuel lines will cause inaccurate test results. All high pressure fuel lines used on the test stand should be checked every three months.

Always use a wrench to hold the hex fitting on top of the master nozzle, when assembling or disassembling lines. If a wrench is not used, the master nozzle and manifold it is installed into may be damaged.

Check fuel line for "Close-in" Do NOT use fuel lines with an ID (inside diameter) LESS than 1.191 mm (0.0469 in). The fuel line ID can be checked using a 1.2 mm (.047 in) drill.If the drill bit can NOT be inserted into the fuel line high pressure hole, either drill out the line using a 1.6 mm (.063 in) drill or replace the fuel line with a new line. Use the same length and internal diameter lines each time the reference pump is tested.

If the fuel lines are not completely and thoroughly cleaned out after the drilling procedure, metal particles or foreign debris in the line will damage the master nozzles and contaminate the calibration fluid in the test stand.

After the hole has been drilled to the correct size, clean the line with solvent and remove any metal particles. Blow compressed air through the lines, after cleaning, to remove any solvent.

When using pressure air, wear a protective face shield and protective clothing. The maximum air pressure at the nozzle must be less than 205 kPa (30 psi) for cleaning purposes.

9. Identify fuel lines and nozzles in the same order as the reference pump plunger and barrels (1-6 or 1-12) and use the same lines and nozzles each time the reference pump is run on the test bench.10. Select two test points (speeds and shot settings) that will cover the delivery range realized in a dealer's shop.Always set up the test points using only the pump rack

1. Select a pump typically serviced in your dealer shop. Do NOT use electronic (PEEC) fuel pumps as reference parts. A 3306B pump is recommended for your reference pump.2. If necessary, disassemble and visually inspect pump cam, lifters, plunger and barrel, etc. to assure all internal components are in good condition.3. Check pump plunger and barrel bonnet nut torque. Torque nuts to recommended value according to the service manual.4. Back out the pump governor load stop(s) and idle setting screws.5. Obtain the required pump rack zero pin. It is recommended each reference pump have its own zero pin (order a spare from the parts department) and permanently attach to the reference pump.6. Install the reference pump on the test stand.7. Make sure the test stand has the latest master fuel nozzles. All master nozzles must have the same part number.8. Inspect each test stand high pressure fuel line inside diameter (ID) for "close-in" from repeated use.Repeated assembly of the high pressure fuel lines can cause the tubing's inside diameter to collapse or "close-in", resulting in low delivery volume. Testing fuel injection pumps using worn or partially closed high pressure fuel lines will cause inaccurate test results. All high pressure fuel lines used on the test stand should be checked every three months.

Always use a wrench to hold the hex fitting on top of the master nozzle, when assembling or disassembling lines. If a wrench is not used, the master nozzle and manifold it is installed into may be damaged.

Check fuel line for "Close-in" Do NOT use fuel lines with an ID (inside diameter) LESS than 1.191 mm (0.0469 in). The fuel line ID can be checked using a 1.2 mm (.047 in) drill.If the drill bit can NOT be inserted into the fuel line high pressure hole, either drill out the line using a 1.6 mm (.063 in) drill or replace the fuel line with a new line. Use the same length and internal diameter lines each time the reference pump is tested.

If the fuel lines are not completely and thoroughly cleaned out after the drilling procedure, metal particles or foreign debris in the line will damage the master nozzles and contaminate the calibration fluid in the test stand.

After the hole has been drilled to the correct size, clean the line with solvent and remove any metal particles. Blow compressed air through the lines, after cleaning, to remove any solvent.

When using pressure air, wear a protective face shield and protective clothing. The maximum air pressure at the nozzle must be less than 205 kPa (30 psi) for cleaning purposes.

9. Identify fuel lines and nozzles in the same order as the reference pump plunger and barrels (1-6 or 1-12) and use the same lines and nozzles each time the reference pump is run on the test bench.10. Select two test points (speeds and shot settings) that will cover the delivery range realized in a dealer's shop.Always set up the test points using only the pump rack