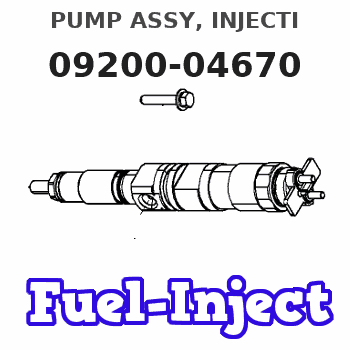

Information pump assy, injecti

Nozzle:

0935005480

Rating:

KIT List:

| Pump assy, fuel fe | 1922900060 |

| Body assy, injecti | 1904400300 |

| Governor assy, mec | 1908900170 |

Components :

| 001. | PUMP ASSY, INJECTI | 09200-04670 |

| 002. | PUMP ASSY, FUEL FE | 09210-01291 |

| 003. | BODY ASSY, INJECTI | 19010-00480 |

| 004. | GOVERNOR ASSY, MEC | 19080-06760 |

Scheme ###:

| 000. | [01] | 09200-04670 | PUMP ASSY, INJECTI | 32C6502250 |

| 005. | [01] | 19010-00480 | BODY ASSY, INJECTI | |

| 006. | [01] | 19080-06760 | GOVERNOR ASSY, MEC | |

| 007. | [01] | 09001-80081 | COVER, CONTROL RAC | 09001-80081 |

| 008. | [01] | 94905-02450 | NUT, HEXAGON | 94905-02450 |

| 009. | [01] | 94913-00190 | KEY, WOODRUFF | 94913-00190 |

| 010. | [01] | 94901-50500 | WASHER, SPRING | 94901-50500 |

| 012. | [01] | 09210-01291 | PUMP ASSY, FUEL FE | 34461-09060 |

| 013. | [01] | 91518-08221 | BOLT, W/WASHER | 91518-08221 |

| 014. | [06] | 91418-06161 | BOLT, W/WASHER | 91418-06161 |

Include in #3:

09200-04670

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-04670 | 32C6502250 | PUMP ASSY, INJECTI | |

| 32C6502250 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Problem

Some fuel injectors may fail on certain Challenger 75 Tractors and 3176 Truck Engines.

Affected Product

Model & Identification Number

Challenger 75 (4CJ1-406)

3176 (2YG1-Up; 7LG1-4822)

Parts Needed

Use the following parts in quantities needed to perform repairs. The application of each injector listed is noted. Use remanufactured injectors, unless unavailable.

0R3397 Injector Grp. (4P9510 if reman unavailable for 7LG 250-300 HP)0R3398 Injector Grp. (4P9520 if reman unavailable for 7LG 325 HP and 4CJ)0R3399 Injector Grp. (4P9610 if reman unavailable for 2YG 250-275 HP)0R3400 Injector Grp. (4P9620 if reman unavailable for 2YG 300-325 HP)9X7557 Seal (injector upper O-ring)9X7722 Seal (injector lower O-ring)336044 Seal (injector thrust-pad-retaining O-ring)Action Required

1. Isolate the injector which is causing the problem. Some failure modes require duplication of the conditions where the customer say the problem occurs (i.e. at full load, idle, high speed, low speed, etc.)2. Replace injectors only after verifying a problem using the 1U6661 Unit Injector Tester, cutting out cylinders, etc. Replace any failed injectors according to the rework procedures attached.Service Claim Allowances

This is a 2.5-hour job. Add 0.2 hours for 1st injector diagnostic test and 0.1 hours for each additional injector test. Add 1.2 hours for first injector sleeve replaced and 0.7 hours for each additional sleeve replaced.

3176 Truck Engines

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

1. Drain fuel from the cylinder head and fuel manifold. Remove air inlet piping, valve covers and Jake Brake (if equipped) , rocker arm assemblies, and injector hold down bolts. Remove the suspect injector(s) for inspection and test. Mark each injector to denote the cylinder from which it was removed. It is important to install the injector(s) into the same cylinder to prevent combustion gas leaks.2. Test the injector(s) using the 1U6661 Unit Injector Tester. Check for leaks, VOP, and spray pattern. Replace all injectors which do not pass these test.Procedure For Installing The Following Injector Part Numbers:

4P1410, 4P1420, 4P2810, 4P2820, 0R3177, AND 0R3178

1. Inspect the raised edge on the injector cone for signs of damage. If any nicks or dings are present, do not reuse the injector.2. Ream the sleeves before installing the injectors. Ream only until the sleeve has been cut to provide a full length concentric taper past the injector/sleeve sealing interface. Full removal of the indentation created by the cone step edge is not necessary.3. Install new O-rings on the injector and apply STP ® to prevent cutting during installation.4. Install the injectors, apply 6V4876 Molykote to the hold-down bolt threads and tighten the bolts to 33 NM (24 ft. lb.). Make sure the longer 5P8347 Bolts and 4P8525 Spacers (or 8T0100 Bolts and 4P1711 Spacers) are used.5. Inspect bridge assemblies for wear.Procedures For Installing All Other Injectors:

1. Ream the sleeves before installing the injectors. Ream only until the sleeves have been cut to provide a full length concentric taper past the injector/sleeve sealing interface.2. After reaming, apply a thin coating of liquid machinist's blue (Dykem) to the bottom of the sleeves - allow to dry. Install injector without

Some fuel injectors may fail on certain Challenger 75 Tractors and 3176 Truck Engines.

Affected Product

Model & Identification Number

Challenger 75 (4CJ1-406)

3176 (2YG1-Up; 7LG1-4822)

Parts Needed

Use the following parts in quantities needed to perform repairs. The application of each injector listed is noted. Use remanufactured injectors, unless unavailable.

0R3397 Injector Grp. (4P9510 if reman unavailable for 7LG 250-300 HP)0R3398 Injector Grp. (4P9520 if reman unavailable for 7LG 325 HP and 4CJ)0R3399 Injector Grp. (4P9610 if reman unavailable for 2YG 250-275 HP)0R3400 Injector Grp. (4P9620 if reman unavailable for 2YG 300-325 HP)9X7557 Seal (injector upper O-ring)9X7722 Seal (injector lower O-ring)336044 Seal (injector thrust-pad-retaining O-ring)Action Required

1. Isolate the injector which is causing the problem. Some failure modes require duplication of the conditions where the customer say the problem occurs (i.e. at full load, idle, high speed, low speed, etc.)2. Replace injectors only after verifying a problem using the 1U6661 Unit Injector Tester, cutting out cylinders, etc. Replace any failed injectors according to the rework procedures attached.Service Claim Allowances

This is a 2.5-hour job. Add 0.2 hours for 1st injector diagnostic test and 0.1 hours for each additional injector test. Add 1.2 hours for first injector sleeve replaced and 0.7 hours for each additional sleeve replaced.

3176 Truck Engines

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Attach. (1-Rework Procedure)Rework Procedure

1. Drain fuel from the cylinder head and fuel manifold. Remove air inlet piping, valve covers and Jake Brake (if equipped) , rocker arm assemblies, and injector hold down bolts. Remove the suspect injector(s) for inspection and test. Mark each injector to denote the cylinder from which it was removed. It is important to install the injector(s) into the same cylinder to prevent combustion gas leaks.2. Test the injector(s) using the 1U6661 Unit Injector Tester. Check for leaks, VOP, and spray pattern. Replace all injectors which do not pass these test.Procedure For Installing The Following Injector Part Numbers:

4P1410, 4P1420, 4P2810, 4P2820, 0R3177, AND 0R3178

1. Inspect the raised edge on the injector cone for signs of damage. If any nicks or dings are present, do not reuse the injector.2. Ream the sleeves before installing the injectors. Ream only until the sleeve has been cut to provide a full length concentric taper past the injector/sleeve sealing interface. Full removal of the indentation created by the cone step edge is not necessary.3. Install new O-rings on the injector and apply STP ® to prevent cutting during installation.4. Install the injectors, apply 6V4876 Molykote to the hold-down bolt threads and tighten the bolts to 33 NM (24 ft. lb.). Make sure the longer 5P8347 Bolts and 4P8525 Spacers (or 8T0100 Bolts and 4P1711 Spacers) are used.5. Inspect bridge assemblies for wear.Procedures For Installing All Other Injectors:

1. Ream the sleeves before installing the injectors. Ream only until the sleeves have been cut to provide a full length concentric taper past the injector/sleeve sealing interface.2. After reaming, apply a thin coating of liquid machinist's blue (Dykem) to the bottom of the sleeves - allow to dry. Install injector without