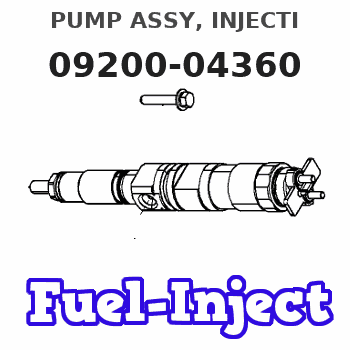

Information pump assy, injecti

Nozzle:

0935006310

Rating:

KIT List:

| Pump assy, fuel fe | 1922900060 |

| Body assy, injecti | 1904400320 |

| Governor assy, mec | 1908900170 |

Components :

| 001. | PUMP ASSY, INJECTI | 09200-04360 |

| 002. | PUMP ASSY, FUEL FE | 09210-01551 |

| 003. | BODY ASSY, INJECTI | 19010-00440 |

| 004. | GOVERNOR ASSY, MEC | 19080-06490 |

| 005. | OVER-HAUL KIT, GOV | 19089-01090 |

| 006. | OVER-HAUL KIT, GOV | 19089-01260 |

Scheme ###:

| 000. | [01] | 09200-04360 | PUMP ASSY, INJECTI | 32A6506070 |

| 005. | [01] | 19010-00440 | BODY ASSY, INJECTI | |

| 006. | [01] | 19080-06490 | GOVERNOR ASSY, MEC | |

| 007. | [01] | 09001-80220 | COVER, CONTROL RAC | |

| 008. | [01] | 94905-03570 | NUT, HEXAGON | |

| 009. | [1C] | 94913-00320 | KEY, WOODRUFF | |

| 009. | [1C] | 94913-00340 | KEY, WOODRUFF | |

| 009. | [1C] | 94913-00360 | KEY, WOODRUFF | |

| 009. | [1C] | 94913-00300 | KEY, WOODRUFF | |

| 010. | [01] | 94901-50590 | WASHER, SPRING | |

| 012. | [01] | 09210-01551 | PUMP ASSY, FUEL FE | 34461-09050 |

| 013. | [01] | 91518-08221 | BOLT, W/WASHER | 91518-08221 |

| 014. | [06] | 91418-06161 | BOLT, W/WASHER | 91418-06161 |

| 015. | [01] | 19089-01090 | OVER-HAUL KIT, GOV | 32B6509510 |

| 015. | [01] | 19089-01260 | OVER-HAUL KIT, GOV | 32B6519510 |

| 015-001. | [02] | 09103-10260 | NUT, CAP | |

| 015-001. | [02] | 09103-10310 | NUT, CAP | |

| 015-002. | [01] | 09103-10270 | NUT, CAP | |

| 015-002. | [01] | 09103-10320 | NUT, CAP | |

| 015-003. | [01] | 09103-10360 | NUT, CAP | |

| 015-003. | [01] | 09103-10280 | NUT, CAP | |

| 015-004. | [02] | 94914-02141 | O-RING | |

| 015-004. | [02] | 94914-04060 | O-RING | |

| 015-005. | [02] | 94907-21500 | RING, SNAP | |

| 015-006. | [01] | 94901-81020 | WASHER, COPPER PLA | 94901-81020 |

Include in #3:

09200-04360

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-04360 | 32A6506070 | PUMP ASSY, INJECTI | |

| 32A6506070 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Start By:a. remove valve covers Call out (1) and (2) are not used in this removal procedure. Call outs begin with number (3). 1. Remove bolts (3) that hold the valve cover bases to the cylinder head assembly. Remove valve cover bases (4).

To prevent damage to the fuel injection nozzle, hold adapter assembly (5) in position at the of injection nozzle (6) when fuel line nut (7) is loosened or tightened.

2. Use Tool (A) and a 7/8 5P0328 Crow Foot ( in) to loosen the fuel injection line nut at the nozzle end. 3. Use Tool (B) to loosen the nut at the fuel injection line adapter end. Remove inner fuel injection lines (8). Install caps and plugs on all fuel injection line openings to keep dirt out of the fuel system. 4. Remove bolts (9) that hold the rocker shaft assemblies to the cylinder head assembly.5. Remove rocker shaft assemblies (10). 6. Put identification marks on the push rods as to their location in the engine. Remove push rods (11). 7. Put identification marks on the bridges as to their location in the engine. Remove bridges (12) from the dowels on the cylinder head assembly.Install Rocker Shaft Assemblies & Push Rods

1. Put clean engine oil on the bridges and dowels. Install the original bridges in their respective locations. New bridges can be mixed.2. Install bridges (1) on the bridge dowels. While firmly pressing 0.5 to 4.5 kg (1 to 10 lb) straight down on the top contact surface of the bridge, turn the adjusting screw clockwise until contact is made with the valve stem. Turn the screw an additional 1/31/2 20 to 30 degrees ( to of 1 hex on nut). This will straighten the dowel in the guide and compensate for the slack in the threads. Hold the adjusting screw in this position and tighten the locknut to a torque of 30 4 N m (22 3 lb ft). Install the original push rods in their respective locations in the engine. New push rods can be mixed.3. Install push rods (2). 4. Put rocker shaft assemblies (3) in position on the cylinder head assembly.5. Put clean engine oil on the threads of the bolts that hold the rocker shaft assemblies in place. Tighten the bolts first to a torque of 270 25 N m (200 18 lb ft). Start with the bolt in the center of the rocker shaft assembly. Tighten the bolts again to a torque of 450 20 N m (330 15 lb ft). Tighten the bolts again by hand to a torque of 450 20 N m (330 15 lb ft).

Do not cause damage to the O-ring seals on the inner fuel lines.

6. Install inner fuel injection lines (4). Tighten the fuel injection line adapter nuts (5) to a torque 40 7 N m (30 5 lb ft) with Tool (A).

Do not let the tops of the fuel nozzles turn when the fuel

To prevent damage to the fuel injection nozzle, hold adapter assembly (5) in position at the of injection nozzle (6) when fuel line nut (7) is loosened or tightened.

2. Use Tool (A) and a 7/8 5P0328 Crow Foot ( in) to loosen the fuel injection line nut at the nozzle end. 3. Use Tool (B) to loosen the nut at the fuel injection line adapter end. Remove inner fuel injection lines (8). Install caps and plugs on all fuel injection line openings to keep dirt out of the fuel system. 4. Remove bolts (9) that hold the rocker shaft assemblies to the cylinder head assembly.5. Remove rocker shaft assemblies (10). 6. Put identification marks on the push rods as to their location in the engine. Remove push rods (11). 7. Put identification marks on the bridges as to their location in the engine. Remove bridges (12) from the dowels on the cylinder head assembly.Install Rocker Shaft Assemblies & Push Rods

1. Put clean engine oil on the bridges and dowels. Install the original bridges in their respective locations. New bridges can be mixed.2. Install bridges (1) on the bridge dowels. While firmly pressing 0.5 to 4.5 kg (1 to 10 lb) straight down on the top contact surface of the bridge, turn the adjusting screw clockwise until contact is made with the valve stem. Turn the screw an additional 1/31/2 20 to 30 degrees ( to of 1 hex on nut). This will straighten the dowel in the guide and compensate for the slack in the threads. Hold the adjusting screw in this position and tighten the locknut to a torque of 30 4 N m (22 3 lb ft). Install the original push rods in their respective locations in the engine. New push rods can be mixed.3. Install push rods (2). 4. Put rocker shaft assemblies (3) in position on the cylinder head assembly.5. Put clean engine oil on the threads of the bolts that hold the rocker shaft assemblies in place. Tighten the bolts first to a torque of 270 25 N m (200 18 lb ft). Start with the bolt in the center of the rocker shaft assembly. Tighten the bolts again to a torque of 450 20 N m (330 15 lb ft). Tighten the bolts again by hand to a torque of 450 20 N m (330 15 lb ft).

Do not cause damage to the O-ring seals on the inner fuel lines.

6. Install inner fuel injection lines (4). Tighten the fuel injection line adapter nuts (5) to a torque 40 7 N m (30 5 lb ft) with Tool (A).

Do not let the tops of the fuel nozzles turn when the fuel