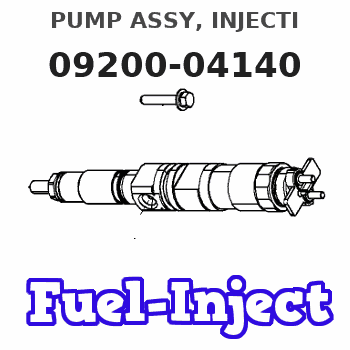

Information pump assy, injecti

Nozzle:

0935006000

Rating:

KIT List:

| Governor assy, mec | 1908900271 |

| Timer assy, automa | No Application |

| Pump assy, fuel fe | 1922900060 |

| Body assy, injecti | No Application |

Components :

| 001. | PUMP ASSY, INJECTI | 09200-04140 |

| 002. | GOVERNOR ASSY, MEC | 09130-06780 |

| 003. | LEVER SET | 09129-10020 |

| 004. | COVER ASSY, GOVERN | 09145-00143 |

| 005. | TIMER ASSY, AUTOMA | 09180-03840 |

| 006. | PUMP ASSY, FUEL FE | 09210-02520 |

| 007. | BODY ASSY, INJECTI | 19010-01090 |

Scheme ###:

| 000. | [01] | 09200-04140 | PUMP ASSY, INJECTI | ME170429 |

| 005. | [01] | 19010-01090 | BODY ASSY, INJECTI | ME743068 |

| 006. | [01] | 09130-06780 | GOVERNOR ASSY, MEC | ME743564 |

| 007. | [01] | 09001-80090 | COVER, CONTROL RAC | ME702251 |

| 008. | [01] | 94914-02840 | O-RING | MH035502 |

| 009. | [01] | 09006-00371 | COVER SUB-ASSY, TI | ME728195 |

| 010. | [01] | 09180-03840 | TIMER ASSY, AUTOMA | ME743074 |

| 011. | [04] | 94905-02680 | NUT, HEXAGON | ME702046 |

| 011. | [04] | 91266-10081 | NUT, HEXAGON | MF430122 |

| 012. | [04] | 90258-10001 | WASHER, SPRING | MC327716 |

| 013. | [02] | 94901-15020 | WASHER, STEEL PLAT | MH005068 |

| 014. | [01] | 90458-04051 | KEY, WOODRUFF | ME728066 |

| 015. | [01] | 94901-40210 | WASHER, COUNTERSUN | ME702043 |

| 016. | [01] | 09001-20220 | NUT, TIMER ROUND | ME702033 |

| 017. | [01] | 09210-02520 | PUMP ASSY, FUEL FE | ME728199 |

| 018. | [01] | 09009-20100 | BRACKET | ME702036 |

| 019. | [01] | 94904-73910 | BOLT, W/WASHER | ME703449 |

| 020. | [05] | 94904-72690 | BOLT, W/WASHER | ME702045 |

| 021. | [01] | 91418-06201 | BOLT, W/WASHER | ME702041 |

| 022. | [01] | 09069-11320 | BRACKET, STOP WIRE | ME703775 |

| 023. | [01] | 09028-50021 | CAP | ME035845 |

| 024. | [01] | 09028-50050 | CAP | ME076458 |

Include in #3:

09200-04140

as PUMP ASSY, INJECTI

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-04140 | ME170429 | PUMP ASSY, INJECTI | |

| ME170429 | MITSUBISHI | PUMP ASSY, INJECTI |

Information:

Start By:a. remove vibration damper

The crankshaft front seal and wear sleeve come as a set and must be installed as a set. If a replacement of the seal is to be made, a replacement of the wear sleeve must also be made.

1. Make at least three holes in seal (1) with a hammer and a sharp punch.2. Use Tool (A) to remove seal (1). 3. Install Tool (C) in the seal bore.4. Install Tool (B) between Tool (C) and wear sleeve (2). Turn Tool (B) until the Tool makes a dent (crease) in wear sleeve (2). Do this in three or more places until the wear sleeve is loose.5. Remove Tools (B) and (C), and remove wear sleeve (2) from the crankshaft.Install Crankshaft Front Seal & Wear Sleeve

The crankshaft seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, Form No. SMHS8508, that is included with each seal and wear sleeve before any handling of the seal group is made.

1. Install the front crankshaft seal and wear sleeve with Tool (A). Use the procedures with follows:a. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 6V1541 Quick Cure Primer. Make an application of 9S3265 Retaining Compound to the crankshaft outside diameter before the wear sleeve is installed on the crankshaft. Do not let any 6V1541 Quick Cure Primer or 9S3265 Retaining Compound get on the lip of the seal.b. Install locator (3) and bolts (4) on the crankshaft.c. Seal (1) and wear sleeve (2) must be installed dry.

Make sure the seal is installed with the part number and the arrows showing crankshaft rotation toward the outside.

The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving the oil back into the engine.

d. Put wear sleeve (2) and seal (1) as a unit in position on locator (3).e. Put installer (5) in position on locator (3).f. Put clean engine oil on the face of nut (6) and its contact area on installer (5). Install nut (6) on locator (3).g. Tighten nut (6) until the inside surface of installer (5) comes in contact with locator (3).h. Remove Tool (D) from the crankshaft seal and wear sleeve. Tool (D) will install the seal and wear sleeve to the correct depth on the crankshaft.End By:a. install vibration damper

The crankshaft front seal and wear sleeve come as a set and must be installed as a set. If a replacement of the seal is to be made, a replacement of the wear sleeve must also be made.

1. Make at least three holes in seal (1) with a hammer and a sharp punch.2. Use Tool (A) to remove seal (1). 3. Install Tool (C) in the seal bore.4. Install Tool (B) between Tool (C) and wear sleeve (2). Turn Tool (B) until the Tool makes a dent (crease) in wear sleeve (2). Do this in three or more places until the wear sleeve is loose.5. Remove Tools (B) and (C), and remove wear sleeve (2) from the crankshaft.Install Crankshaft Front Seal & Wear Sleeve

The crankshaft seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, Form No. SMHS8508, that is included with each seal and wear sleeve before any handling of the seal group is made.

1. Install the front crankshaft seal and wear sleeve with Tool (A). Use the procedures with follows:a. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 6V1541 Quick Cure Primer. Make an application of 9S3265 Retaining Compound to the crankshaft outside diameter before the wear sleeve is installed on the crankshaft. Do not let any 6V1541 Quick Cure Primer or 9S3265 Retaining Compound get on the lip of the seal.b. Install locator (3) and bolts (4) on the crankshaft.c. Seal (1) and wear sleeve (2) must be installed dry.

Make sure the seal is installed with the part number and the arrows showing crankshaft rotation toward the outside.

The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving the oil back into the engine.

d. Put wear sleeve (2) and seal (1) as a unit in position on locator (3).e. Put installer (5) in position on locator (3).f. Put clean engine oil on the face of nut (6) and its contact area on installer (5). Install nut (6) on locator (3).g. Tighten nut (6) until the inside surface of installer (5) comes in contact with locator (3).h. Remove Tool (D) from the crankshaft seal and wear sleeve. Tool (D) will install the seal and wear sleeve to the correct depth on the crankshaft.End By:a. install vibration damper