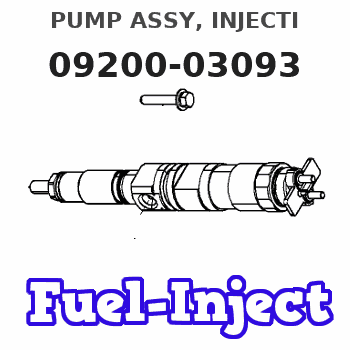

Information pump assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09200-03093 | PUMP ASSY, INJECTI | 22010-8221 |

| 000. | [01] | 09200-03093 | PUMP ASSY, INJECTI | 22010-E0200 |

| 003. | [01] | 19010-00472 | BODY ASSY, INJECTI | 22110-3600A |

| 003. | [01] | 19010-01401 | BODY ASSY, INJECTI | 22110-3611A |

| 004. | [01] | 09130-05624 | GOVERNOR ASSY, MEC | S2231-05870-A |

| 005. | [01] | 09180-03742 | TIMER ASSY, AUTOMA | S2251-03060-A |

| 006. | [01] | 09001-20340 | NUT, TIMER ROUND | S2282-52240-A |

| 007. | [01] | 09250-01061 | COUPLING ASSY | S2261-01860-A |

| 008. | [01] | 90458-05750 | KEY, WOODRUFF | S2289-11070-A |

| 009. | [01] | 09210-02810 | PUMP ASSY, FUEL FE | 22570-1600A |

| 009. | [01] | 09210-03150 | PUMP ASSY, FUEL FE | S2257-01740-A |

| 010. | [01] | 09001-80381 | COVER, CONTROL RAC | S2211-41200-A |

| 011. | [01] | 94901-81550 | WASHER, COPPER PLA | SL722-02215 |

| 012. | [01] | 94904-76900 | BOLT, W/WASHER | S2281-53230-A |

| 013. | [04] | 94904-76890 | BOLT, W/WASHER | S2281-53210-A |

| 014. | [01] | 94904-76910 | BOLT, W/WASHER | S2281-53240-A |

| 015. | [02] | 94904-76880 | BOLT, W/WASHER | S2281-53320-A |

| 018. | [01] | 09028-50030 | CAP | S2232-31210-A |

| 019. | [01] | 09028-50050 | CAP | S2232-31430-A |

| 021. | [02] | 94901-02480 | WASHER | S2284-71940-A |

| 022. | [01] | 09031-00450 | VALVE ASSY, OVERFL | S2210-71570-A |

| 023. | [02] | 91808-08121 | BOLT, FLANGE | S2281-53330-A |

| 024. | [01] | 09069-00900 | BRACKET SUB-ASSY, | S2204-41330-A |

| 025. | [02] | 91808-08201 | BOLT, FLANGE | S2281-53390-A |

| 026. | [01] | 09045-30190 | STAY, INJECTION PU | S1140-91270-C |

| 027. | [01] | 09028-50030 | CAP | S2232-31210-A |

Include in #3:

09200-03093

as PUMP ASSY, INJECTI

09200-03093

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-03093 | 22010-8221 | PUMP ASSY, INJECTI |

Information:

The 5P-4150 Tester Group is used for testing:* Capsule-Type Fuel Valves* Pencil-Type Fuel Nozzles* Caterpillar Direct Injection Fuel Nozzles The additional tools referenced in this manual are needed for testing or cleaning specific fuel valves and nozzles or are part of 8S-2245 Cleaning Tool Group. These tools are available from the Parts Department. The 8T-0860 and 8T-0856 Pressure Gauges, 1U-9578 Repair Kit (not shown), 8T-5313 Nozzle Test Filter (1), and 6V-0183 Pump Body Gasket (2) are all available from the Parts Department.Install a new 8T-5313 Nozzle Tester Filter (1) at least once every three months, or more often when necessary. Install a new 6V-0183 Pump Body Gasket (2) when necessary. For nozzle cleaning procedure, refer to Special Instruction SEHS8627 entitled "Use Of 8S2245 Nozzle Cleaning Tool Group".Reference: Service Manual Parts Book, Special Instruction SEHS8627 "Use of 8S2245 Nozzle Cleaning Tool Group", SEHS7390 "Test Sequence For Pencil-Type Fuel Nozzles".General Information

When testing either new nozzles or nozzles that are not suspected of a failure, it is permissible to flush each nozzle three full strokes before the test.It is necessary to have an accurate record of the test results for each nozzle that is tested. Record the results of each nozzle test procedure on SEHS8144 "Nozzle Test Record".These test sheets are available through Miscellaneous Order Division. Pads containing 50 sheets may be ordered with special instruction SEHS8144. A copy of SEHS8144 is shown at the back of this manual. Always keep the reservoir filled with CLEAN calibration fluid. Low oil level will cause SOFT or SPONGY operation of the tester pump. Use SAE J-967 Calibration Fluid in the tester. Order calibration fluid, according to the amount needed, by the following part numbers.6V-6067 Calibration Fluid...208 L (54.9 gal U.S.) Drum6V-6068 Calibration Fluid...19 L (5.0 gal U.S.) Pail9U-7411 Calibration Fluid...3.8 L (1.0 gal U.S.) PailHave the pressure gauges checked and calibrated at least once each year. Checking and calibration should be performed more often if the test results become inconsistent of inaccuracy is suspected. There are two methods for gauge calibration. Gauge calibration should be checked using the 5P-8558 Pressure Gauge Calibrating Group or calibrated by the gauge manufacture.This manual contains the instructions for gauge calibration when using 5P-8558 Pressure Gauge Calibrating Group. This Manual also contains the procedures to follow if the gauges are sent to the manufacturer for calibration.Refer to "Calibration (Method 1 or Method 2)" in this manual.The rate of 8T-0856 Pressure Gauge is 0-6000 kPa (0-870 psi) with minor divisions (increments) of 100 kPa (20 psi).The range of 8T-0860 Pressure Gauge is 0-40 000 kPa (0-5800 psi) with minor divisions (increments) of 1000 kPa (100 psi).The accuracy for either gauge is 2.0 percent full scale across the entire readable range.The test information in this manual has been obtained by comparison tests of fuel nozzles known to be good. These tests are not intended to be a duplication of conditions that exist during engine operation.The tests in this manual will provide an indication of nozzle condition. A nozzle that

When testing either new nozzles or nozzles that are not suspected of a failure, it is permissible to flush each nozzle three full strokes before the test.It is necessary to have an accurate record of the test results for each nozzle that is tested. Record the results of each nozzle test procedure on SEHS8144 "Nozzle Test Record".These test sheets are available through Miscellaneous Order Division. Pads containing 50 sheets may be ordered with special instruction SEHS8144. A copy of SEHS8144 is shown at the back of this manual. Always keep the reservoir filled with CLEAN calibration fluid. Low oil level will cause SOFT or SPONGY operation of the tester pump. Use SAE J-967 Calibration Fluid in the tester. Order calibration fluid, according to the amount needed, by the following part numbers.6V-6067 Calibration Fluid...208 L (54.9 gal U.S.) Drum6V-6068 Calibration Fluid...19 L (5.0 gal U.S.) Pail9U-7411 Calibration Fluid...3.8 L (1.0 gal U.S.) PailHave the pressure gauges checked and calibrated at least once each year. Checking and calibration should be performed more often if the test results become inconsistent of inaccuracy is suspected. There are two methods for gauge calibration. Gauge calibration should be checked using the 5P-8558 Pressure Gauge Calibrating Group or calibrated by the gauge manufacture.This manual contains the instructions for gauge calibration when using 5P-8558 Pressure Gauge Calibrating Group. This Manual also contains the procedures to follow if the gauges are sent to the manufacturer for calibration.Refer to "Calibration (Method 1 or Method 2)" in this manual.The rate of 8T-0856 Pressure Gauge is 0-6000 kPa (0-870 psi) with minor divisions (increments) of 100 kPa (20 psi).The range of 8T-0860 Pressure Gauge is 0-40 000 kPa (0-5800 psi) with minor divisions (increments) of 1000 kPa (100 psi).The accuracy for either gauge is 2.0 percent full scale across the entire readable range.The test information in this manual has been obtained by comparison tests of fuel nozzles known to be good. These tests are not intended to be a duplication of conditions that exist during engine operation.The tests in this manual will provide an indication of nozzle condition. A nozzle that