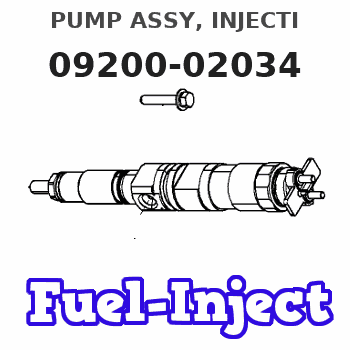

Information pump assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09200-02034 | PUMP ASSY, INJECTI | 22010-7621 |

| 000. | [01] | 09200-02034 | PUMP ASSY, INJECTI | S2201-07621-J |

| 003. | [01] | 19010-00930 | BODY ASSY, INJECTI | 22110-3240A |

| 003. | [01] | 19010-01510 | BODY ASSY, INJECTI | 22110-3670A |

| 004. | [01] | 09130-05553 | GOVERNOR ASSY, MEC | S2231-05813-A |

| 005. | [01] | 09180-03710 | TIMER ASSY, AUTOMA | S2251-02810-A |

| 006. | [01] | 09001-20340 | NUT, TIMER ROUND | S2282-52240-A |

| 007. | [01] | 09250-01061 | COUPLING ASSY | S2261-01860-A |

| 008. | [01] | 90458-05750 | KEY, WOODRUFF | S2289-11070-A |

| 009. | [01] | 09210-02630 | PUMP ASSY, FUEL FE | S2257-01500-A |

| 009. | [01] | 09210-03170 | PUMP ASSY, FUEL FE | S2257-01730-A |

| 010. | [01] | 09001-80381 | COVER, CONTROL RAC | S2211-41200-A |

| 011. | [01] | 94901-81550 | WASHER, COPPER PLA | SL722-02215 |

| 012. | [01] | 94904-76900 | BOLT, W/WASHER | S2281-53230-A |

| 013. | [04] | 94904-76890 | BOLT, W/WASHER | S2281-53210-A |

| 014. | [01] | 94904-76910 | BOLT, W/WASHER | S2281-53240-A |

| 015. | [02] | 94904-76880 | BOLT, W/WASHER | S2281-53320-A |

| 018. | [01] | 09028-50030 | CAP | S2232-31210-A |

| 019. | [01] | 09028-50050 | CAP | S2232-31430-A |

| 021. | [01] | 09031-00380 | VALVE ASSY, OVERFL | S2210-71430-A |

| 022. | [02] | 94901-02480 | WASHER | S2284-71940-A |

| 023. | [02] | 91808-08121 | BOLT, FLANGE | S2281-53330-A |

| 024. | [01] | 09069-00632 | BRACKET SUB-ASSY, | S2234-35351-A |

| 025. | [02] | 91808-08201 | BOLT, FLANGE | S2281-53390-A |

| 026. | [01] | 09045-30170 | STAY, INJECTION PU | S1140-91230-B |

Include in #3:

09200-02034

as PUMP ASSY, INJECTI

09200-02034

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-02034 | 22010-7621 | PUMP ASSY, INJECTI |

Information:

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.