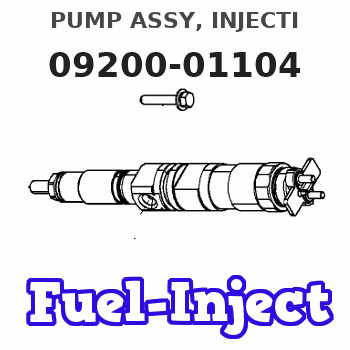

Information pump assy, injecti

Rating:

Scheme ###:

| 000. | [01] | 09200-01104 | PUMP ASSY, INJECTI | 22010-7453 |

| 000. | [01] | 09200-01104 | PUMP ASSY, INJECTI | |

| 003. | [01] | 09210-03170 | PUMP ASSY, FUEL FE | 22570-1730A |

| 003. | [01] | 09210-03170 | PUMP ASSY, FUEL FE | |

| 003. | [01] | 09210-02630 | PUMP ASSY, FUEL FE | |

| 003. | [01] | 09210-02630 | PUMP ASSY, FUEL FE | 22570-1500A |

| 004. | [01] | 09031-00380 | VALVE ASSY, OVERFL | |

| 004. | [01] | 09031-00380 | VALVE ASSY, OVERFL | 22107-1430A |

| 005. | [02] | 94901-02480 | WASHER | 90099-01501 |

| 005. | [02] | 94901-02480 | WASHER | 22847-1940A |

| 006. | [01] | 09001-80090 | COVER, CONTROL RAC | 22116-56230 |

| 006. | [01] | 09001-80090 | COVER, CONTROL RAC | 22114-1250A |

| 007. | [05] | 94904-72690 | BOLT, W/WASHER | 90099-04319 |

| 007. | [05] | 94904-72690 | BOLT, W/WASHER | 22815-2410A |

| 009. | [01] | 91418-06201 | BOLT, W/WASHER | 90091-20608 |

| 009. | [01] | 91418-06201 | BOLT, W/WASHER | 22815-1290A |

| 010. | [01] | 09028-50030 | CAP | |

| 010. | [01] | 09028-50030 | CAP | 22323-1210A |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 90099-04346 |

| 011. | [01] | 94904-73910 | BOLT, W/WASHER | 22815-2820A |

| 012. | [01] | 19010-00561 | BODY ASSY, INJECTI | 22110-3260A |

| 012. | [01] | 19010-00561 | BODY ASSY, INJECTI | |

| 013. | [01] | 09250-01051 | COUPLING ASSY | 22610-1810A |

| 013. | [01] | 09250-01050 | COUPLING ASSY | |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | |

| 014. | [01] | 09001-20220 | NUT, TIMER ROUND | 22611-78030 |

| 015. | [01] | 09180-03580 | TIMER ASSY, AUTOMA | 22510-2700A |

| 015. | [01] | 09180-03580 | TIMER ASSY, AUTOMA | |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 90099-01500 |

| 016. | [01] | 94901-40210 | WASHER, COUNTERSUN | 22867-1320A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 22895-1080A |

| 017. | [01] | 90458-04051 | KEY, WOODRUFF | 95161-20413 |

| 018. | [01] | 09130-05001 | GOVERNOR ASSY, MEC | 22310-5510A |

| 018. | [01] | 09130-05000 | GOVERNOR ASSY, MEC | |

| 019. | [01] | 09028-50050 | CAP | 22323-1320A |

| 019. | [01] | 09028-50050 | CAP |

Include in #3:

09200-01104

as PUMP ASSY, INJECTI

09200-01104

Cross reference number

| Part num | Firm num | Firm | Name |

| 09200-01104 | 22010-7453 | PUMP ASSY, INJECTI |

Information:

Structure And Operation

Cooling System (Flow of Coolant)

Thermostat

* The thermostat is a bottom bypass type that uses a wax-filled pellet as its flow-regulating element. When the wax is heated, it melts from solid to liquid, changing its total volume. This allows the valve to open or close in accordance with the coolant temperature, regulating and adjusting the flow of coolant to the radiator and to the cylinder head (bypassing the radiator).Water Pump

* The water pump has a drain hole to prevent coolant from entering the unit bearing in the case of defect of the unit seal.Troubleshooting

General Inspection And Adjustment

Inspection And Adjustment Of Belt Tension

* Make sure that there is no oil or grease on the belts. Belts soiled with oil or grease may easily slip, resulting in deteriorated performance of the cooling system.* The water pump pulley is driven by two belts. Always replace the two belts simultaneously to ensure that both belts have the same tension.

Service Standards (Unit: mm) Special Tools Inspection and Cleaning Procedure Inspection: Tension of belts * Press each belt at a central portion between pulleys with a force of approximately 98 N {10 kgf} as shown in the illustration and measure the amount of deflection of the belt.A: Crankshaft pulleyB: Water pump pulleyC: Alternator pulley* Place the small O-ring on

at the scale mark corresponding to 98N {10 kgf} (press force). * Place the large O-ring on

at the scale mark corresponding to the maximum permissible deflection value specified for the belt.* Place

at a central portion between pulleys of the belt and push the handle (indicated by the arrow in the illustration) until the O-ring touches the flange. *Measure the amount of deflection of the belt. * If the measured value deviates from the standard value range, adjust the tension of the belt as follows. Adjustment of belts * Loosen the alternator mounting bolt, and adjust the tension of the belt by moving the alternator as required.* After the adjustment is completed, retighten the mounting bolt firmly.

* Excessive tension in the belt may damage not only the belt itself but also the bearings of the related components.

Inspection of Belts

* Visually check the belts for possible cracks and damage. Belt replacement time varies depending on the severity of cracks and damage that may be found through the check. Study the table given below for the applicable replacement time. Coolant Replacement and Cleaning of Cooling System

Tightening Torque (Unit: N m {kgf m}) * Using the radiator for extended periods of time without cleaning can increase chance of rust and scale formation, which may cause engine overheating. The cooling system must be cleaned periodically.Draining of Coolant

* Opening the pressure cap while the coolant temperature is still high can cause hot coolant to spray out. Cover the pressure cap with a cloth, and loosen it slowly to let the pressure out before opening it fully.

* Drain the coolant only after it has cooled sufficiently to avoid getting scalded.

Cleaning Procedure

* Keep the coolant temperature at approximately 90°C so that the thermostat

Cooling System (Flow of Coolant)

Thermostat

* The thermostat is a bottom bypass type that uses a wax-filled pellet as its flow-regulating element. When the wax is heated, it melts from solid to liquid, changing its total volume. This allows the valve to open or close in accordance with the coolant temperature, regulating and adjusting the flow of coolant to the radiator and to the cylinder head (bypassing the radiator).Water Pump

* The water pump has a drain hole to prevent coolant from entering the unit bearing in the case of defect of the unit seal.Troubleshooting

General Inspection And Adjustment

Inspection And Adjustment Of Belt Tension

* Make sure that there is no oil or grease on the belts. Belts soiled with oil or grease may easily slip, resulting in deteriorated performance of the cooling system.* The water pump pulley is driven by two belts. Always replace the two belts simultaneously to ensure that both belts have the same tension.

Service Standards (Unit: mm) Special Tools Inspection and Cleaning Procedure Inspection: Tension of belts * Press each belt at a central portion between pulleys with a force of approximately 98 N {10 kgf} as shown in the illustration and measure the amount of deflection of the belt.A: Crankshaft pulleyB: Water pump pulleyC: Alternator pulley* Place the small O-ring on

at the scale mark corresponding to 98N {10 kgf} (press force). * Place the large O-ring on

at the scale mark corresponding to the maximum permissible deflection value specified for the belt.* Place

at a central portion between pulleys of the belt and push the handle (indicated by the arrow in the illustration) until the O-ring touches the flange. *Measure the amount of deflection of the belt. * If the measured value deviates from the standard value range, adjust the tension of the belt as follows. Adjustment of belts * Loosen the alternator mounting bolt, and adjust the tension of the belt by moving the alternator as required.* After the adjustment is completed, retighten the mounting bolt firmly.

* Excessive tension in the belt may damage not only the belt itself but also the bearings of the related components.

Inspection of Belts

* Visually check the belts for possible cracks and damage. Belt replacement time varies depending on the severity of cracks and damage that may be found through the check. Study the table given below for the applicable replacement time. Coolant Replacement and Cleaning of Cooling System

Tightening Torque (Unit: N m {kgf m}) * Using the radiator for extended periods of time without cleaning can increase chance of rust and scale formation, which may cause engine overheating. The cooling system must be cleaned periodically.Draining of Coolant

* Opening the pressure cap while the coolant temperature is still high can cause hot coolant to spray out. Cover the pressure cap with a cloth, and loosen it slowly to let the pressure out before opening it fully.

* Drain the coolant only after it has cooled sufficiently to avoid getting scalded.

Cleaning Procedure

* Keep the coolant temperature at approximately 90°C so that the thermostat